Transparent highly heat conductive adhesive tape and preparation method thereof

A technology of high thermal conductivity and thermally conductive adhesives, applied in adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of unsightly appearance of electrical appliances, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

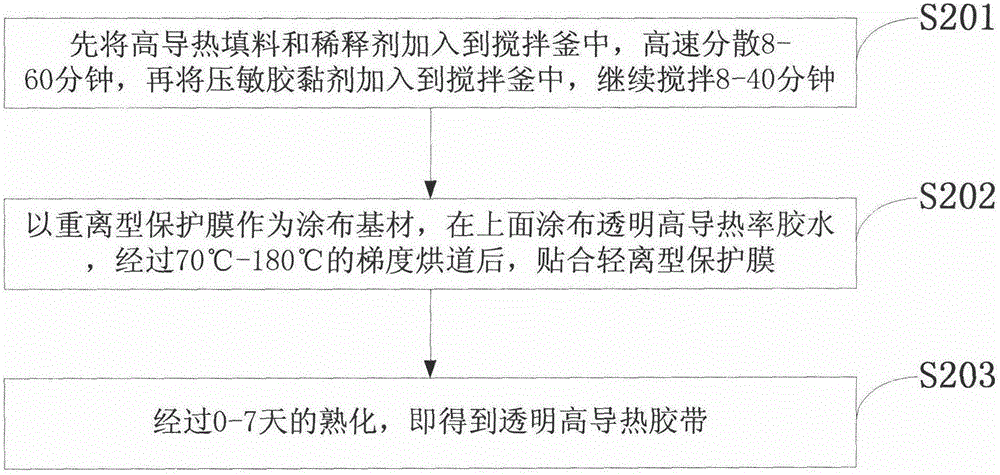

[0029] Such as figure 2 As shown, the preparation method of the transparent high thermal conductivity adhesive tape of the embodiment of the present invention comprises the following steps:

[0030] S201: First add the high thermal conductivity filler and diluent into the stirring tank, disperse at high speed for 8-60 minutes, then add the pressure-sensitive adhesive into the stirring tank, and continue stirring for 8-40 minutes;

[0031] S202: Use the heavy-release protective film as the coating substrate, coat transparent high thermal conductivity glue on it, and stick the light-release protective film after passing through the gradient oven at 70°C-180°C;

[0032] S203: After aging for 0-7 days, a transparent high thermal conductivity tape is obtained.

[0033] The pressure-sensitive adhesive of the present invention can be a one-component adhesive or a two-component adhesive.

[0034] The diluent of the present invention can be one or more of ethyl acetate, butyl acetat...

Embodiment 1

[0037] The following scale factors are all mass percentages:

[0038] Main agent: Acrylic pressure sensitive adhesive 47%;

[0039] Thermally conductive filler: nano silver wire 3%;

[0040] Thermally conductive filler: nano-alumina 20%;

[0041] Diluent: ethyl acetate 30%;

[0042] According to the above formula, disperse the filler in the solvent, stir for 20 minutes, add the main agent glue, and stir for another 10 minutes. The dispersion liquid was coated on the heavy-release protective film to ensure that the dry film thickness was 15 μm after exiting the drying tunnel, and the light-release protective film was attached, and then aged at 50°C for 2 days to obtain the thermally conductive tape of Example 1.

Embodiment 2

[0044] The following scale factors are all mass percentages:

[0045] Main agent: silane pressure sensitive adhesive 50%;

[0046] Thermally conductive filler: CNT 5%;

[0047] Thermally conductive filler: nano diamond powder 15%;

[0048] Diluent: ethyl acetate 35%;

[0049] According to the above formula, disperse the filler in the solvent, stir for 30 minutes, add the main agent glue, and stir for another 10 minutes. The dispersion liquid was coated on the heavy-release protective film to ensure a dry film thickness of 10 μm after exiting the drying tunnel, and then the light-release protective film was attached to obtain the thermally conductive adhesive tape of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com