A chemical-mechanical polishing solution and applications thereof

A chemical-mechanical, polishing liquid technology, applied in the manufacture of polishing compositions containing abrasives, electrical components, semiconductor/solid-state devices, etc., can solve problems such as corrosion, butterfly depression, etc., and achieve the effect of high polishing removal rate

Inactive Publication Date: 2015-05-27

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Patent 200710172711.7 discloses a polishing solution that can improve excessive corrosion, protrusions and sawtooth phenomena on the edge during barrier layer polishing, but the polishing solution desc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

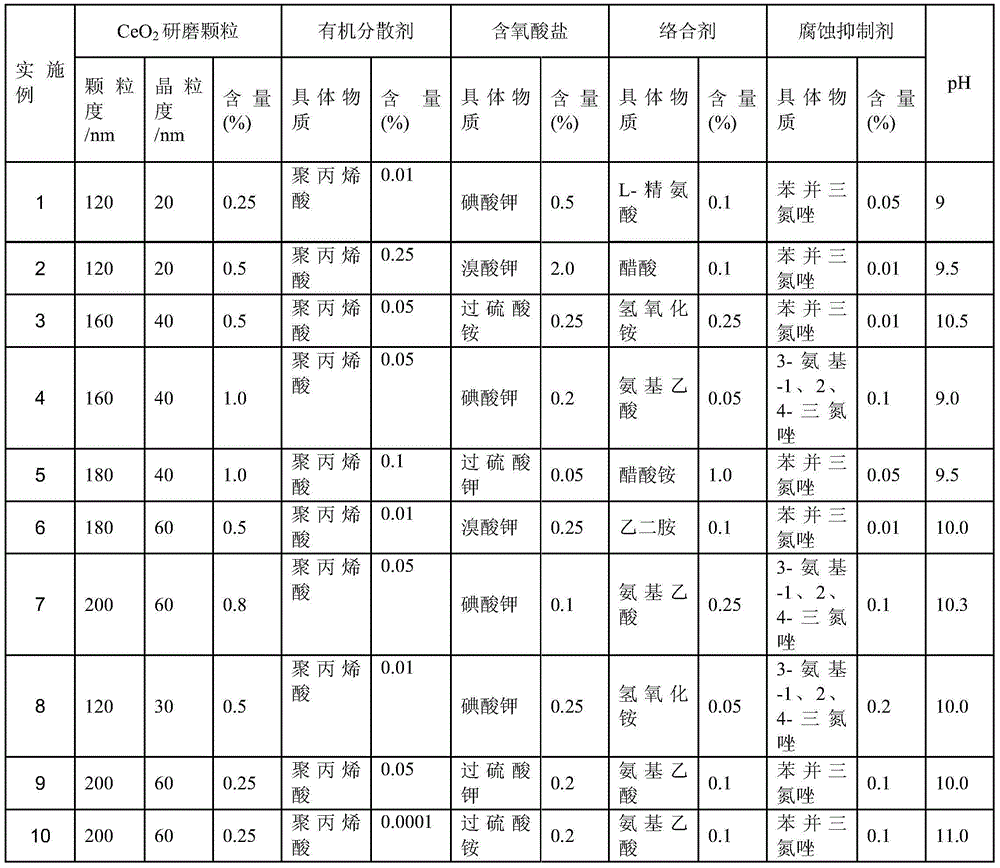

The invention discloses a chemical-mechanical polishing solution used for polishing barrier layers. The polishing solution comprises abrasive particles, oxysalt, a complexing agent, an organic dispersing agent, a corrosion inhibitor, a pH conditioning agent and deionized water. The polishing solution is characterized in that: the polishing solution has adjustable TEOS and Cu polishing speeds under a low cerium oxide solid content, and the polishing solution shows high Ta and Ti polishing and removing speeds especially under the synergistic effect of the oxysalt.

Description

technical field [0001] The invention discloses a chemical mechanical polishing fluid for polishing barrier layer and application thereof. Background technique [0002] With the development of integrated circuits towards high integration, copper has gradually replaced aluminum as interconnect materials, mainly because copper has relatively low resistivity, high anti-electromobility and short RC delay time, which can effectively improve chip performance. The yield rate is reduced, the number of layers of wiring is reduced, and the processing time is shortened. But copper is easily soluble in many dielectric materials, so a diffusion barrier layer is required to prevent copper from diffusing into the underlying dielectric material. Conventional barrier layer materials include titanium, titanium nitride, tantalum, tantalum nitride, etc. [0003] Chemical mechanical planarization (CMP) technology is currently the most reliable and low-cost method for manufacturing flat substrate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09G1/02H01L21/321

CPCC09G1/02H01L21/321

Inventor 尹先升房庆华王雨春

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com