A method for determining the limit distance of co-processing sludge in thermal power plants

A technology of co-processing and extreme distance, applied in combustion methods, sludge treatment, electrical digital data processing, etc., can solve problems such as economic constraints and achieve the effect of promoting the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

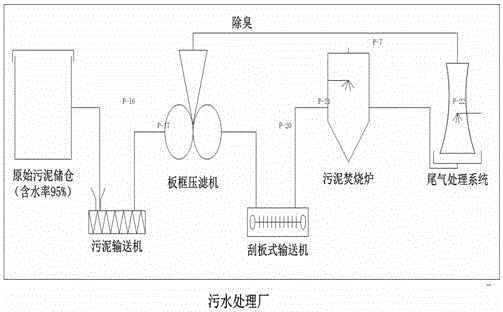

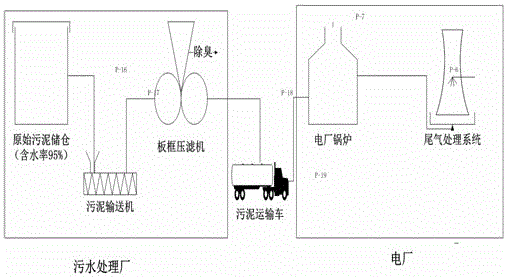

[0034] The present invention provides a method for determining the limit distance of co-processing sludge in thermal power plants. The following three technical routes for sludge disposal are used as examples to specifically illustrate how the present invention determines the limit distance. The technical route for co-processing sludge in power plants in the present invention is not Limited to routes (1) and (3) below.

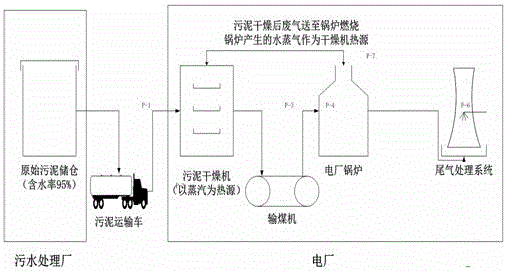

[0035] (1) Technical route for co-firing sludge drying in thermal power plants:

[0036] Such as figure 1 As shown, the sludge with a water content of 95% produced by the sewage treatment plant is directly transported to the thermal power plant by vehicle without any treatment, and then dried by a sludge dryer using steam as a heat source (the waste gas generated by the sludge during the drying process is separated by a cyclone After preliminary tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com