Method and system for treating high-concentration wastewater by virtue of low-temperature evaporative crystallization

A high-concentration wastewater treatment method technology, applied in multi-stage water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of easy scaling of equipment, low evaporation efficiency, high cost, etc. Scale reduction, cost reduction, and the effect of avoiding corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

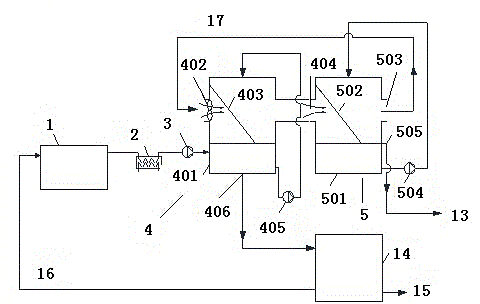

[0032] Such as figure 1 As shown, the method for treating high-concentration wastewater by single-effect low-temperature evaporation and crystallization comprises the following steps:

[0033] (1) Evaporation cycle: The raw water in the raw water tank 1 enters the evaporation chamber 401 of the first effect evaporation module 4 after preheating, and then enters the top of the evaporation chamber 401 through the circulation pump 405; the water at the top of the evaporation chamber 401 flows along the evaporation chamber. The surface of the inclined plate 403 of 401 flows downward, and the wind blown by the fan at the air inlet 402 contacts the water layer on the surface of the inclined plate 403 to generate saturated humid air, which is discharged from the evaporation chamber 401 through the air outlet 404; The concentrated liquid that generates saturated humid air and flows into the bottom of the evaporation chamber 401 is lifted to the top of the evaporation chamber 401 by th...

Embodiment 2

[0038] Such as figure 2 As shown, the double-effect low-temperature evaporation and crystallization method for treating high-concentration wastewater has a treatment capacity of 100m 3 / d, including the following steps:

[0039] (1) Evaporation cycle: The raw water in the raw water tank 1 is preheated by the heater 2 and pumped into the evaporation chamber 401 of the first-effect evaporation module 4 through the raw water pump 3, and then lifted to the second-effect evaporation module 6 by the circulation pump 405 At the top of the evaporation chamber 601, the water flows down along the surface of the inclined plate 603 and flows into the evaporation chamber 601. At the same time, the fan at the air inlet 602 blows to the evaporation chamber 601. The water contacts with the wind to become saturated humid air, and the saturated humid air flows from the outlet to the evaporation chamber 601. The tuyere 604 is discharged into the second-effect condensing module 7; the concentra...

Embodiment 3

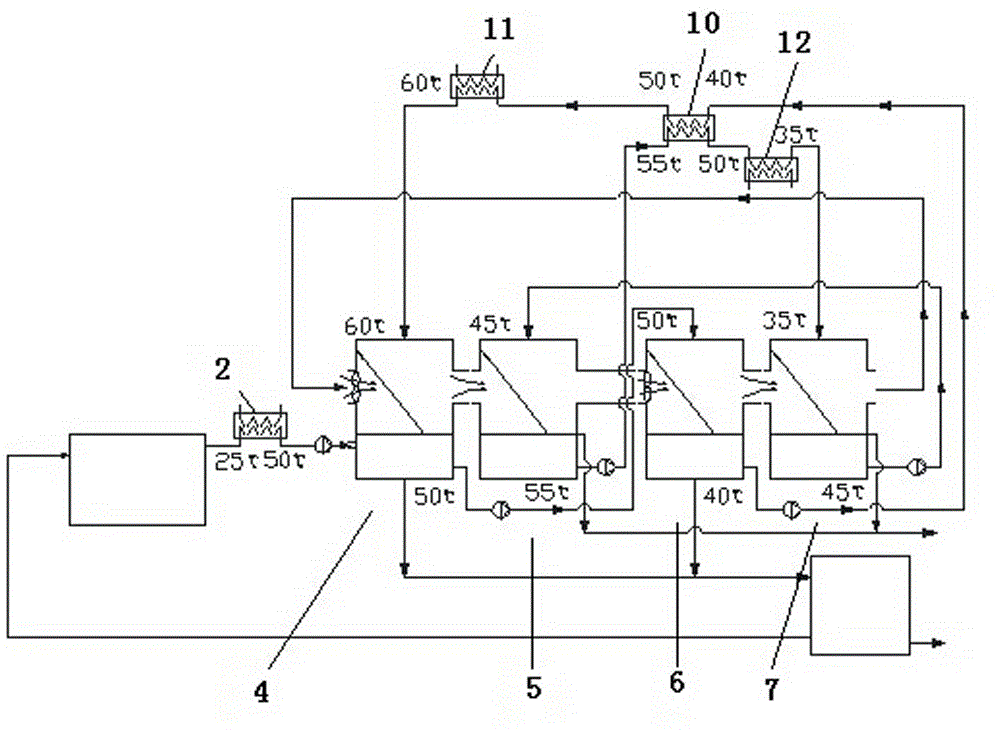

[0047] Such as Figure 4 , a three-effect low-temperature evaporation and crystallization method for treating high-concentration wastewater, with a treatment capacity of 150m 3 / d, including the following steps:

[0048] (1) Evaporation cycle: The raw water in the raw water tank 1 is preheated by the heater 2 and pumped into the evaporation chamber 401 of the first-effect evaporation module 4 through the raw water pump 3, and then lifted by the circulation pump 5 to the second-effect evaporation module 6. At the top of the evaporation chamber 601, water flows down along the surface of the inclined plate 603, and flows into the evaporation chamber 601 of the second effect evaporation module 6. At the same time, the air inlet 602 blows to the evaporation chamber 601, and the wind contacts with the water to become saturated humid air. Air is discharged into the second-effect condensing module 7 from the air outlet 604; the concentrated liquid that does not generate saturated hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com