Condensate removal by means of condensate evaporation in a refrigeration device

A technology for cooling equipment and condensed water, which is applied in lighting and heating equipment, household refrigeration equipment, defrosting, etc., can solve technical troublesome and expensive problems, and achieve the effects of reducing operating costs, compact structure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

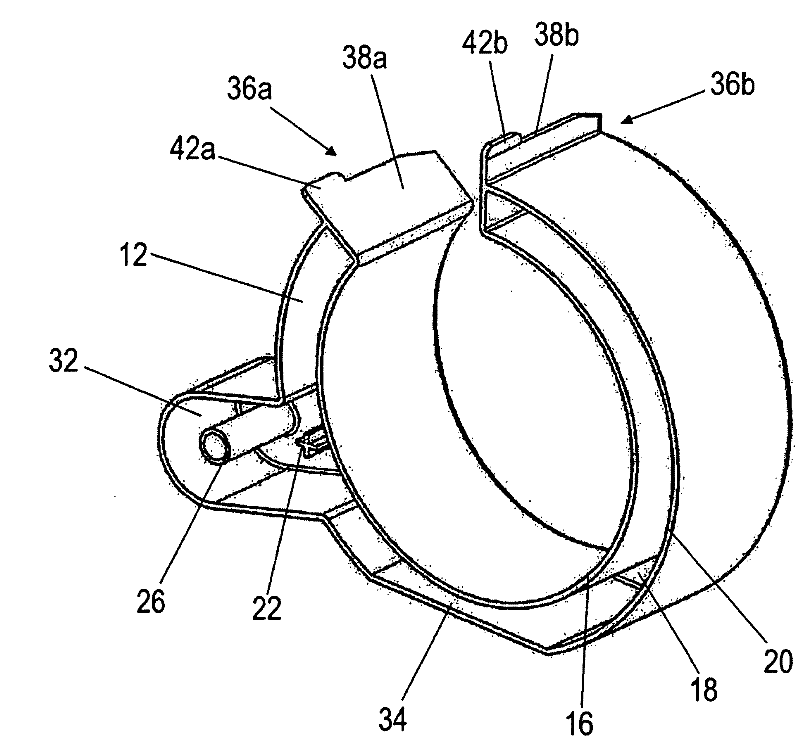

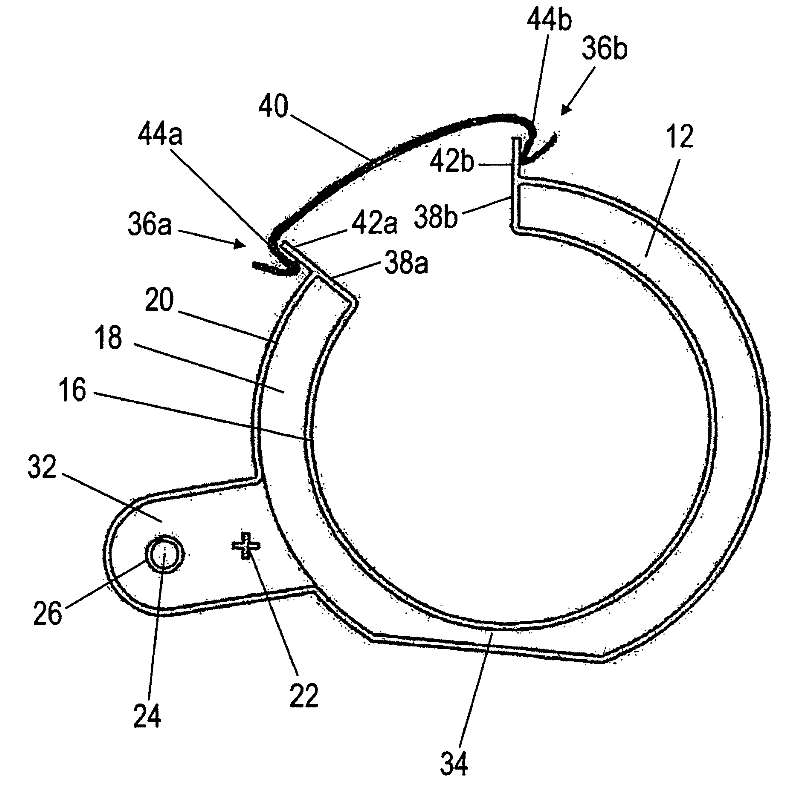

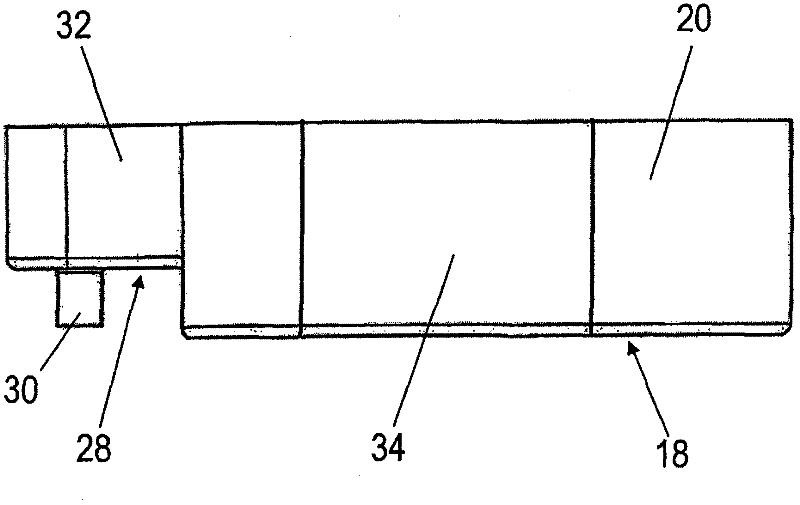

[0028] figure 1 The condensate evaporator is shown as a one-piece plastic die-cast part. The condensate evaporator has a receiving chamber 12 which is designed as a substantially C-shaped collecting trough 12 . The accommodating chamber 12 has a substantially right-angled cross-section that is open upwards and has a thin inner wall 16 , a bottom 18 and an outer wall 20 . This receiving chamber 12 can be connected to a feed hose (not shown) which conducts condensate accumulated on the (not shown) evaporator into the receiving chamber 12 . For this purpose, a stop element 22 is integrally formed on the bottom 18 of the collecting chamber 12 . The retaining element 12 is designed as a cross-shaped sleeve, so that when the supply hose is plugged in, condensation water can flow into the receiving chamber 12 between the cross-shaped ribs of the cross-shaped sleeve.

[0029] figure 2 In a schematic top view showing the figure 1 condensate evaporator. The bottom 18 of the recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com