Pressing suction device

A technology of adjusting device and gland, which is applied in the directions of injection device, packaging, transportation and packaging, etc., can solve the problems of inability to adjust the distance between the liquid outlet pipe and gland and waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

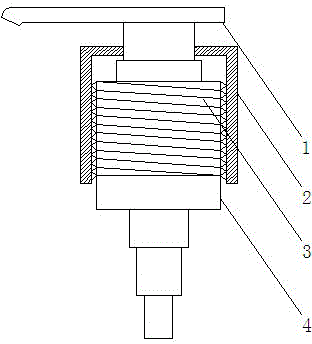

[0008] The present invention will be further described in detail in conjunction with the accompanying drawings. The liquid outlet pipe 1 of the present invention is slid up and down in the hole at the top of the gland 4, and a liquid outlet adjustment device is provided between the gland 4 and the upper end of the liquid outlet pipe 1. The liquid outlet regulating device includes an outer cover 2, the inner side of the outer cover 2 is provided with an internal thread, the outer side of the gland 4 is provided with an external thread 3 matching the inner side of the outer cover, and the internal thread and the external thread 3 are screwed together. The hole at the top of the outer cover 2 is opposite to the hole at the top of the gland 4 , and the outlet pipe 1 slides up and down and is connected in the hole at the top of the outer cover 2 .

[0009] When in use, according to the amount of liquid you usually need, rotate the outer cover 2 to adjust the distance between the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com