Vibration absorbing for railway vehicle

A technology for railway vehicles and underframes, which is applied in the field of pit-vibrated railway vehicle bases, can solve the problems of loss, damage, and compression deformation of shock-absorbing devices, and achieve the effect of increasing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

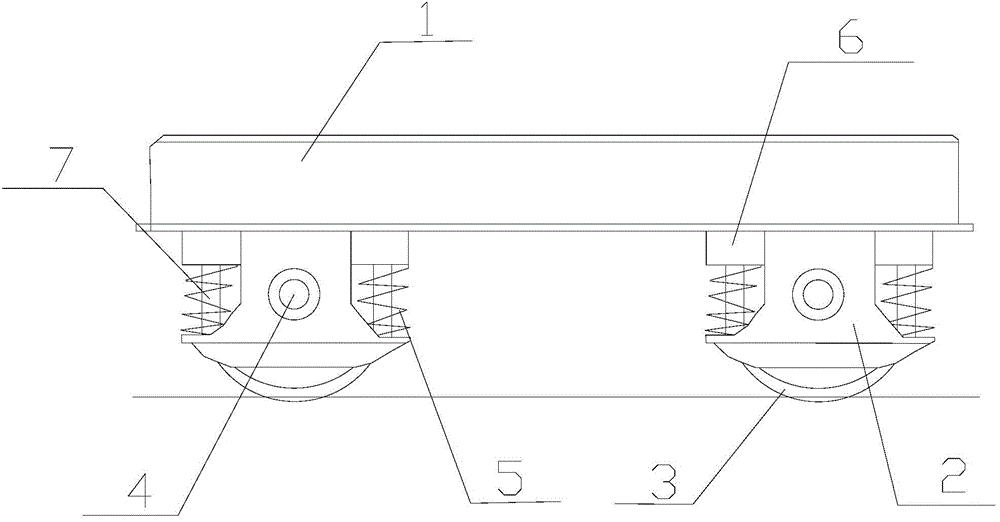

[0010] like figure 1 As shown, a pit-vibration railway vehicle base includes: an underframe 1, a fixed frame 2, a wheel 3, an axle 4, a spring 5, a damping device 6 and a shear pin 7; There are a plurality of fixed mounts 2, and the fixed mounts 2 are connected with wheels 3 through the axles 4, and the two sides of the fixed mounts 2 are provided with shock absorbers 6, and the shock absorber 6 has springs 5, and the shock absorbers A shear pin 7 is installed in the middle of the spring 5 of the device 6 .

[0011] An intermediate hydraulic shock absorber is arranged in the middle of the underframe 1 .

[0012] The bottom frame 1 and the fixed frame 2 are connected by riveting first, and then fixed by welding.

[0013] The base of a pit-vibration railway vehicle according to the present invention is provided with a shear pin in the damping device with a spring, and when the base device suddenly receives a relatively large pressure, the spring on the damping device is presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com