A forming mold and forming method for the hollow block of the silt-promoting embankment

A technology for molding molds and molding methods, which is applied in the direction of molds, ceramic molding machines, ceramic molding cores, etc., can solve problems such as increased construction costs, increased construction complexity, engineering costs, and large throwing volumes, and achieve structural design Simple and reasonable, convenient and labor-saving disassembly and assembly, and the effect of ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

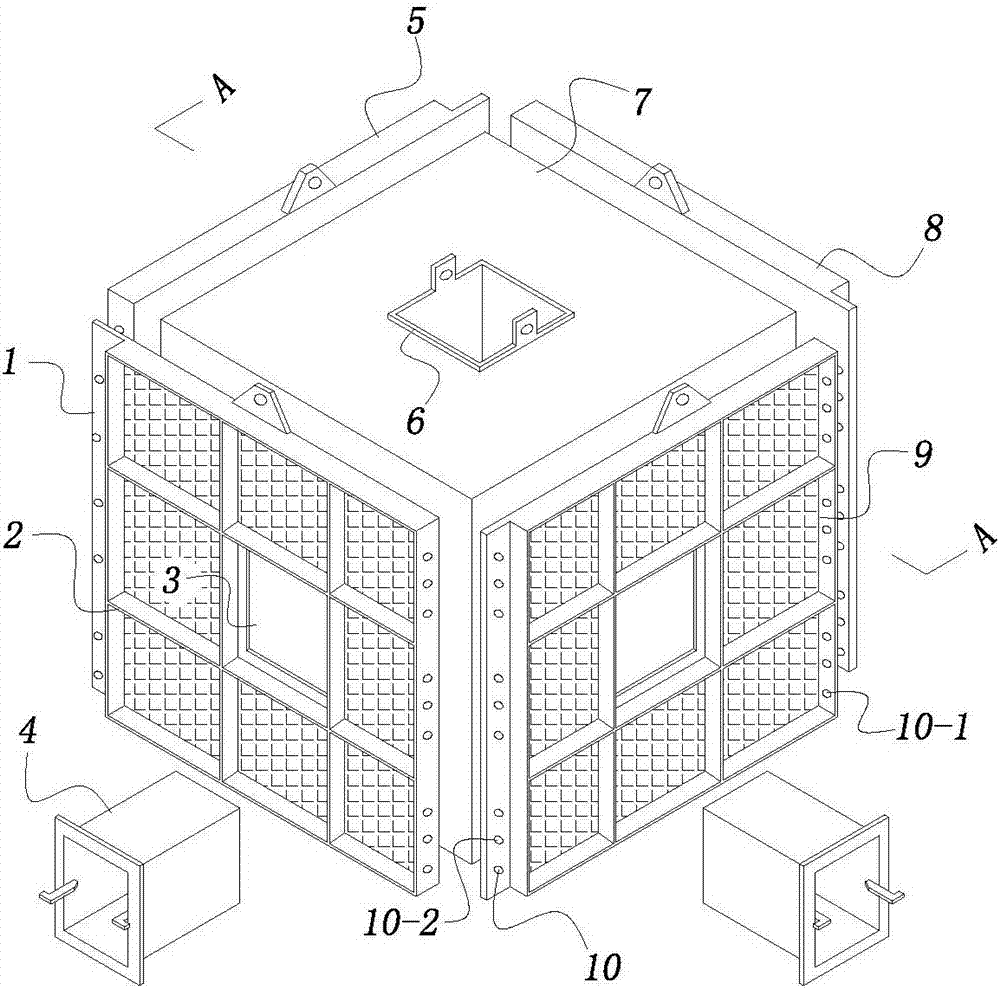

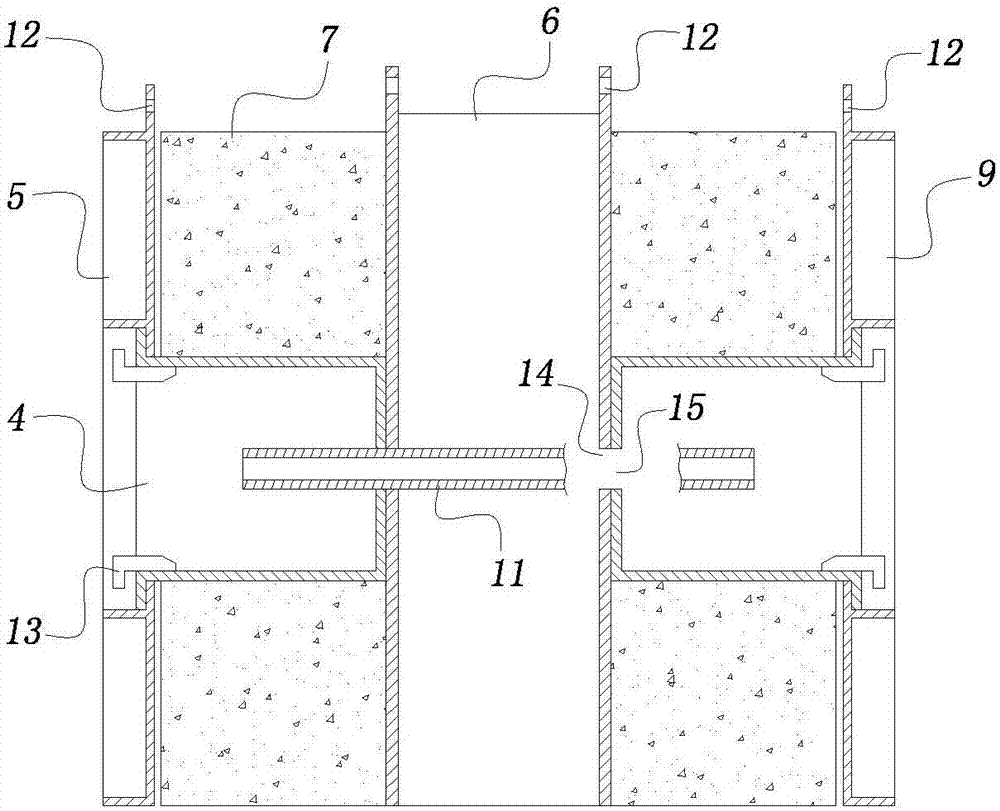

[0017] See figure 1 and figure 2 , the present invention comprises a vertical mandrel 6 with a rectangular cross-section at the center and a first side plate 2, a second side plate 5, a third side plate 8 and a fourth side plate 9 positioned around the vertical mandrel 6 , the four side panels form a frame with a rectangular cross-section, and two adjacent side panels are fixedly connected at the butt edges.

[0018] A square drawer hole 3 is provided at the centers of the first side plate 2 , the second side plate 5 , the third side plate 8 and the fourth side plate 9 . It also includes four drawer-type mandrels 4 with a square cross-section that are inserted laterally into the inner cavity of the frame by the drawer holes 3 of each side plate. the middle of each outer wall.

[0019] The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com