Self-adaption absorptive clamping device of airplane skin

A technology for aircraft skinning and clamping devices, which is applied in the direction of clamping devices, positioning devices, clamping, etc., can solve the problem of unable to adjust the adsorption position adaptively due to skin forming errors, and meet the requirements of low cost and reduced component accuracy , The effect of high adsorption success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention is described further, but the present invention is not limited to this embodiment.

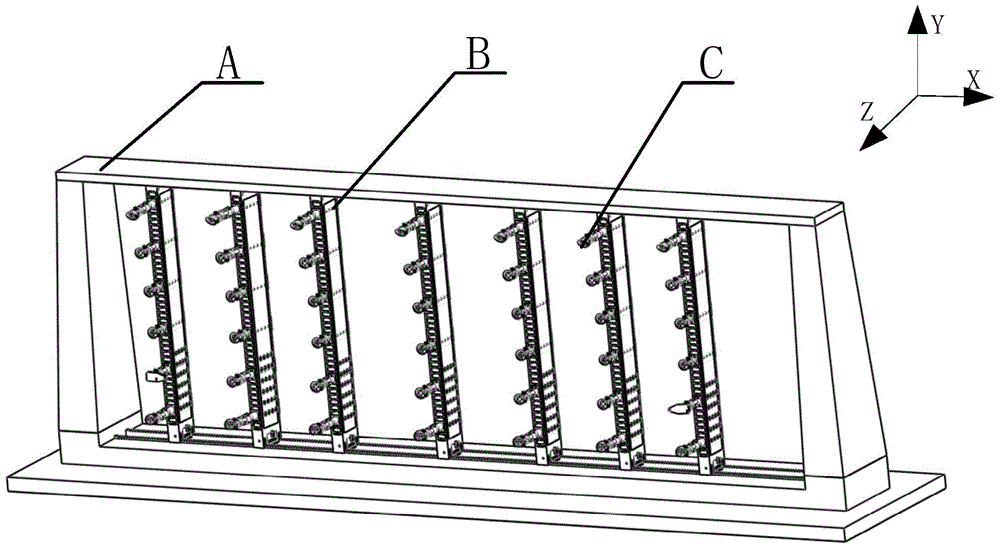

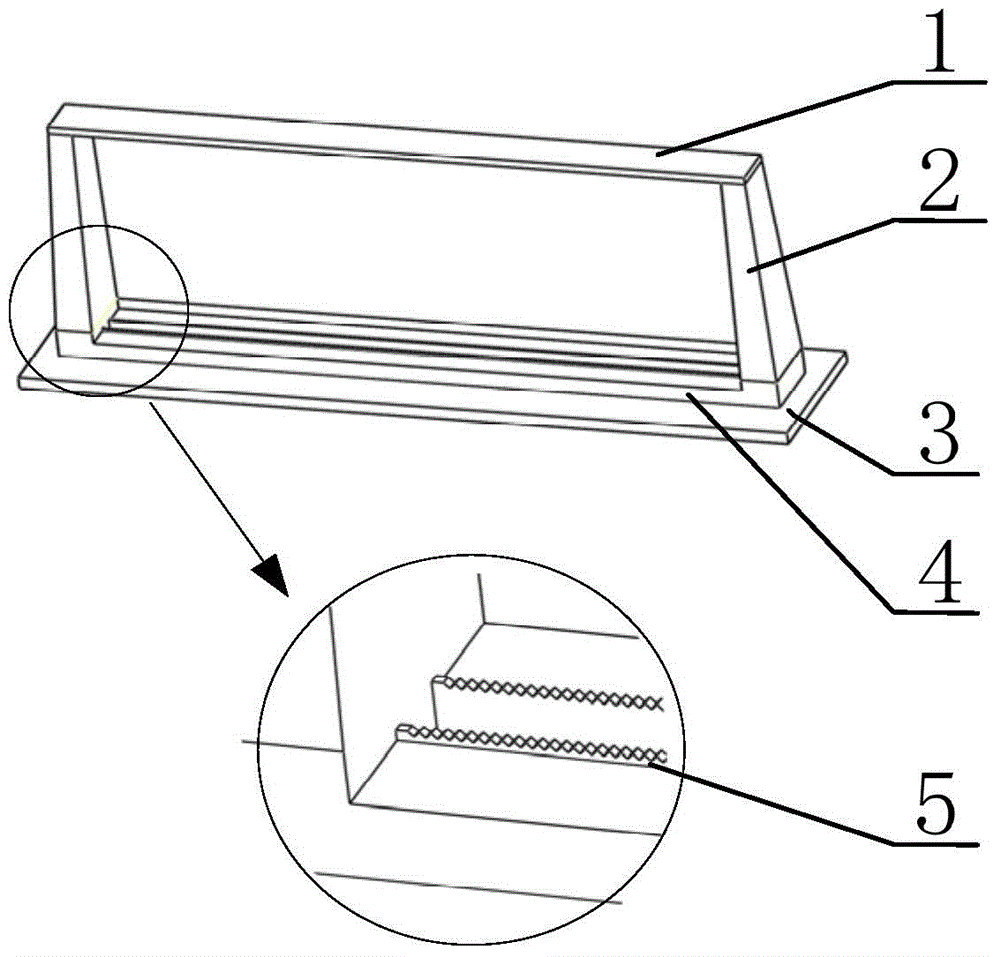

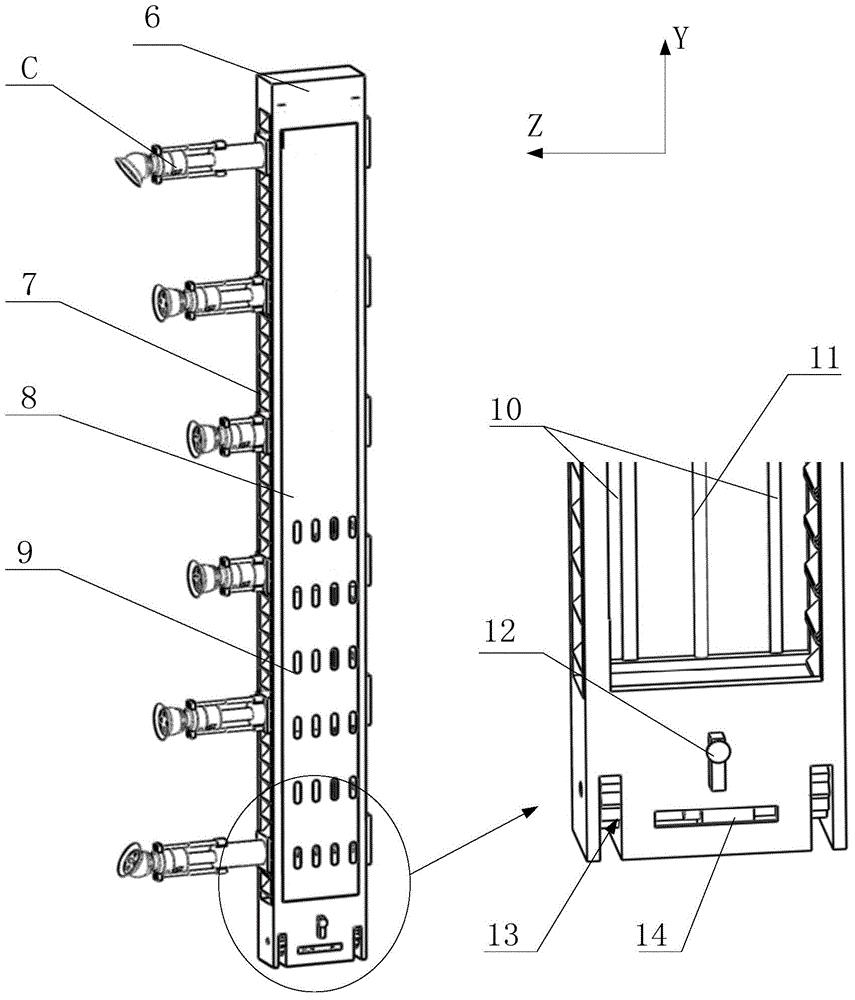

[0037] A skin adaptive adsorption clamping device is suitable for clamping aircraft skins of various shapes and sizes, and includes a frame A, a bent frame B and an adaptive adsorption column C. Such as figure 1 As shown, the upper and lower beams of the frame are respectively equipped with racks; the bent frame is located between the upper and lower beams. The motor I that moves horizontally on the frame, the synchronous movement of the two motors I can make the rack move along the rack on the frame, and the racks need to move in coordination to avoid interference; the racks are equipped with ball wires along the vertical direction Each set of racks is equipped with a certain number of self-adaptive adsorption columns, and each adaptive adsorption column can move up and down along the vertical guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com