Inductive wire end cutting device

A technology of inductance wire and inductance, which is applied in the field of cutting devices for excessively long leads at both ends of the inductance. It can solve the problems of inconsistent length, low production efficiency, and poor stability, and achieve the effects of increased production efficiency, reduced labor intensity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

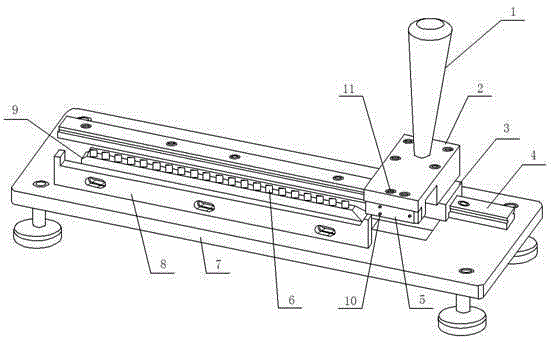

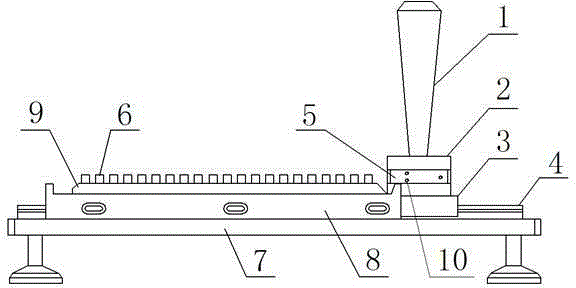

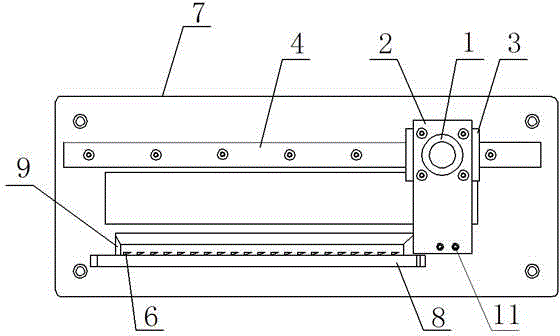

[0016] Such as Figure 1 to Figure 5 The shown inductance lead cutting device includes a base 7 and a positioning seat 9 arranged on the base 7, and a plurality of guides corresponding to the inductance 13 installed on the printing stick 12 are provided at intervals on the top of the positioning seat 9. Block 6, on one side of the positioning seat 9, a rod seat 8 with a gap at the top is provided, on the other side of the positioning seat 9, a guide rail 4 is provided on the base 7, and the guide rail 4 is connected with the knife rest 2 through the guide sleeve 3 , the knife rest 2 is provided with a blade mounting part that stretches out and is placed above the positioning seat 9; the positioning seat 9 is arranged in parallel with the guide rail 4; the knife rest 2 is provided with a handle 1; the positioning seat 9 is provided with a On an inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com