BiOXs pholocatalyst, grapheme-compounded BiOXs pholocatalyst and preparation method thereof

A photocatalyst and graphene technology, applied in the field of photocatalytic materials, can solve the problems affecting photocatalytic performance, material structure changes, etc., and achieve the effects of low production cost, simple production process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

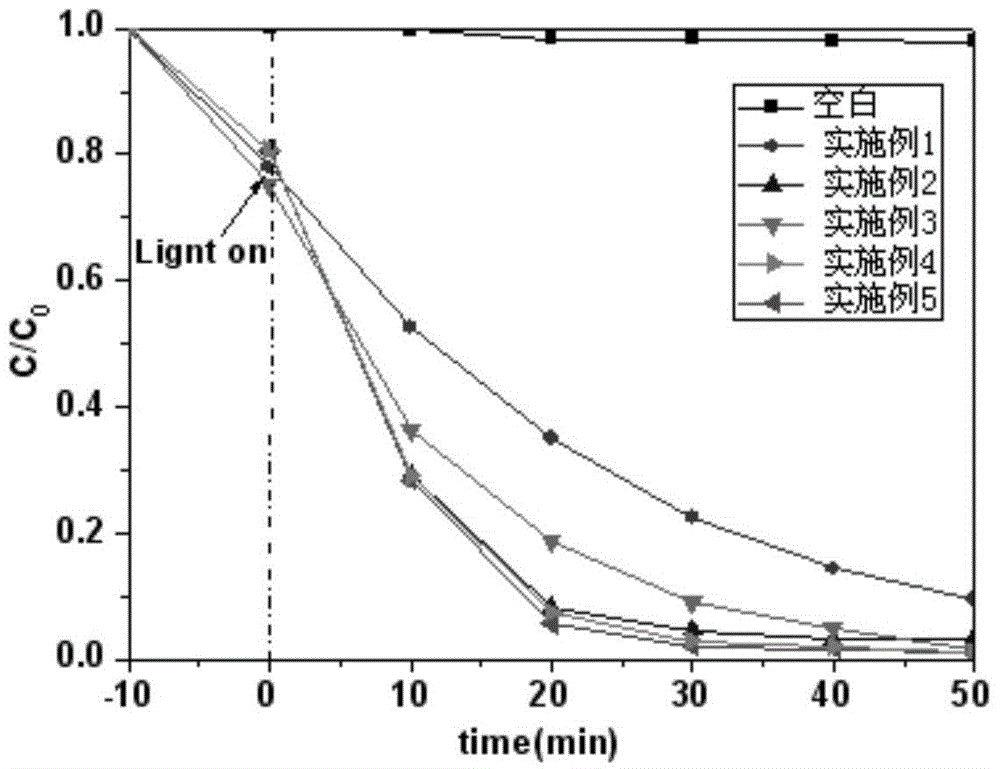

Embodiment 1

[0020] Put 0.005 mol of bismuth nitrate into 40 ml of a solution of ethylene glycol and glacial acetic acid with a volume ratio of 2:1, and magnetically stir for 0.5 hours to fully dissolve it to obtain a solution A. Then 0.005 mol NaBr (KBr can also be used) was added to 40 ml of anhydrous ethanol and deionized water solution with a volume ratio of 2:1, and magnetically stirred for 0.5 hours to fully dissolve it to obtain a B solution. Subsequently, the B solution was slowly added dropwise to the continuously stirred A solution. After the addition, the stirring was continued for 0.5 hours, and then the mixed solution was transferred to a 100ml PTFE-lined stainless steel reactor and reacted at 110°C for 10 hours After the reaction, the precipitate was filtered, washed three times with deionized water and absolute ethanol, and finally placed in an oven at 80°C and dried in vacuum for 8 hours. Grind into powder to obtain a sample whose chemical composition is BiOBr.

[0021] Photo...

Embodiment 2

[0023] Put 0.008 mol of bismuth nitrate into 40 ml of ethylene glycol and glacial acetic acid solution with a volume ratio of 3:1, and magnetically stir for 1 hour to fully dissolve it to obtain a solution A. Then 0.006 mol NaCl and 0.002 mol NaBr were added to 40 ml of anhydrous ethanol and deionized water solution with a volume ratio of 3:1, and magnetically stirred for 1 hour to fully dissolve it to obtain a B solution. Subsequently, the B solution was slowly added dropwise to the continuously stirring A solution. After the addition, the stirring was continued for 0.5 hours, and then the mixed solution was transferred to a 100ml PTFE-lined stainless steel reactor and reacted at 120°C for 12 hours After the reaction, the precipitate was filtered, washed three times with deionized water and absolute ethanol, and finally placed in an oven at 80°C and dried in vacuum for 8 hours. Grind into powder, get sample, its chemical composition is BiOCl 0.75 Br 0.25 .

[0024] Photocatalyt...

Embodiment 3

[0026] Put 0.006 mol of bismuth nitrate into 40 ml of ethylene glycol and glacial acetic acid solution with a volume ratio of 1:1, and magnetically stir for 1 hour to fully dissolve it to obtain a solution A. Then 0.006 mol NaCl was added to 40 ml of anhydrous ethanol and deionized water solution with a volume ratio of 1:1, and magnetically stirred for 1 hour to fully dissolve it to obtain a B solution. Subsequently, the B solution was slowly added dropwise to the continuously stirring A solution. After the addition, the stirring was continued for 0.5 hours, and then the mixed solution was transferred to a 100ml PTFE-lined stainless steel reactor and reacted at 120°C for 12 hours After the reaction, the precipitate was filtered, washed three times with deionized water and absolute ethanol, and finally placed in an oven at 80°C and dried in vacuum for 8 hours. Grind into powder to obtain a sample whose chemical composition is BiOCl.

[0027] Photocatalytic performance test: Put 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com