Detection tool structure for shaft positioning groove of automobile connecting rod

An automobile connecting rod and shaft positioning technology, applied in the direction of mechanical depth measurement, etc., can solve the problems of time-consuming detection and complicated operation, and achieve the effects of convenient calibration, improved measurement accuracy, and small axial expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

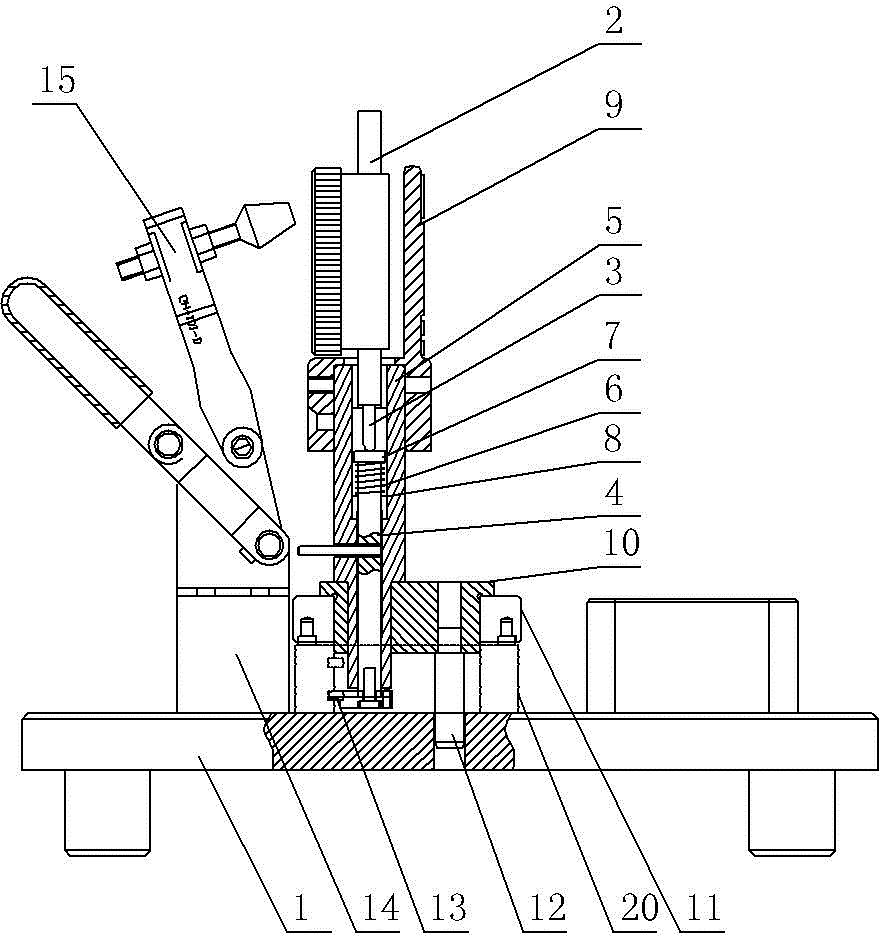

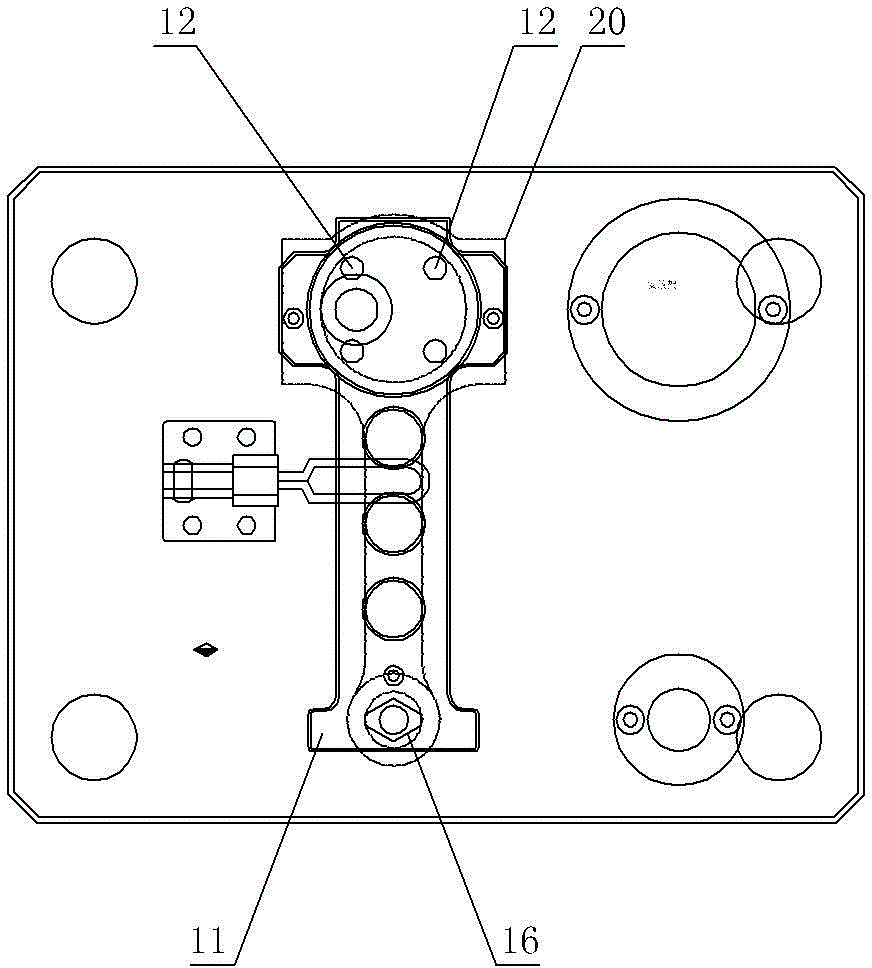

[0018] like figure 1 , figure 2 As shown, the inspection tool structure of the shaft positioning groove of the automobile connecting rod includes a bottom plate 1 and a measuring table device. The positioning pin is arranged on the bottom plate 1, and the measuring rod head of the measuring table device is provided with the shaft positioning groove of the automobile connecting rod. The matching positioning protrusion 13, the positioning protrusion 13 is located at the radial outside of the measuring rod; the measuring gauge device includes a dial indicator 2, a gauge body 5 and a measuring rod, the gauge body 5 is provided with an axial perforation, and the perforation of the gauge body 5 The upper part is equipped with a dial indicator 2, the lower part of the perforation is equipped with a measuring rod 4, and the measuring rod 3 of the dial indicator is installed on the upper end surface of the measuring rod 4; Notch one 7, the spring 6 is also set on the measuring rod 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com