Air pressure damping mechanism and air pressure damping shock absorber with the same

A technology of damping mechanism and shock absorber, applied in the direction of shock absorber, gas shock absorber, spring/shock absorber, etc. The shock effect is stable, the damping force is improved, and the protection is not damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

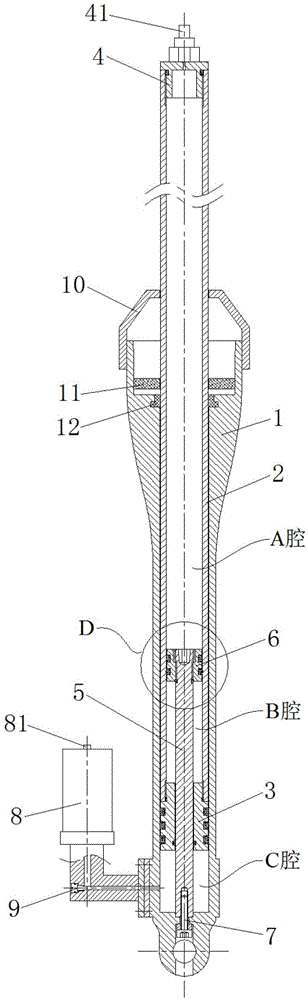

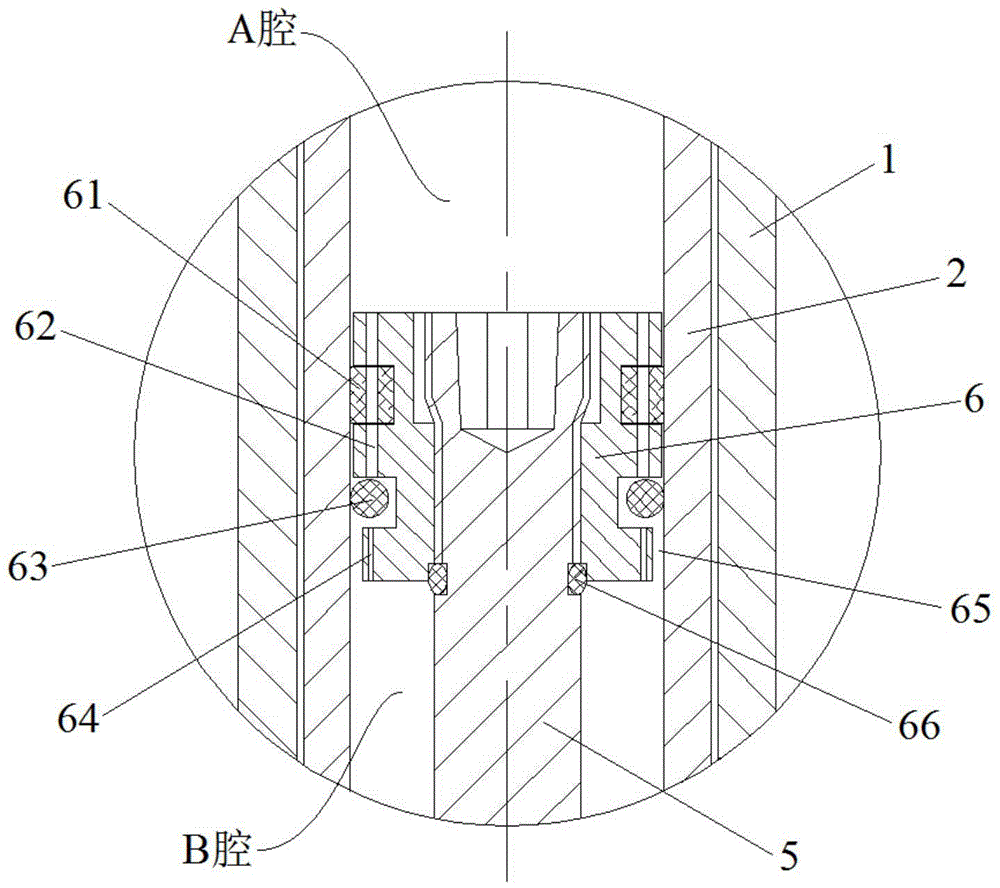

[0034]As shown in Fig. 2, a kind of air pressure damping mechanism of this embodiment includes a handle tube 2 and a piston rod 5 arranged in the handle tube 2, both ends of the handle tube 2 are sealed, and the handle tube 2 is filled with gas, which can It can be air or a mixed gas. One end of the piston rod 5 located in the handle tube 2 is provided with a damping piston 6. The damping piston 6 divides the handle tube 2 into an A chamber and a B chamber. The A chamber is a rodless chamber, and the B chamber It is a rod cavity, and the structure is similar to the cylinder structure, the difference is that the handle tube 2 is a sealed space, and the damping piston 6 has a good gas damping effect; specifically, the damping piston 6 is provided with a sealing ring installation groove, and the sealing ring A floating sealing ring 63 is arranged in the installation groove, and the size of the sealing ring installation groove is appropriately larger than the floating sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com