Outside-disc inside-magnet disc brake

A technology of disc brakes and electromagnetic brakes, applied in the direction of brake types, axial brakes, brake actuators, etc., can solve the problem of not completely solving the thermal degradation of brakes, affecting the reliability of automobile braking, and mutual interference of heat, etc. problems, to avoid mutual interference of heat, avoid overheating and heat decay, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

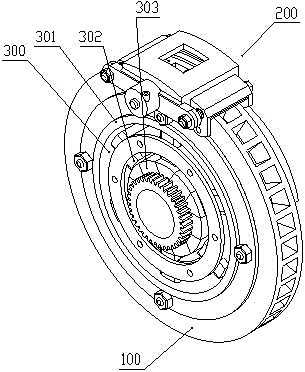

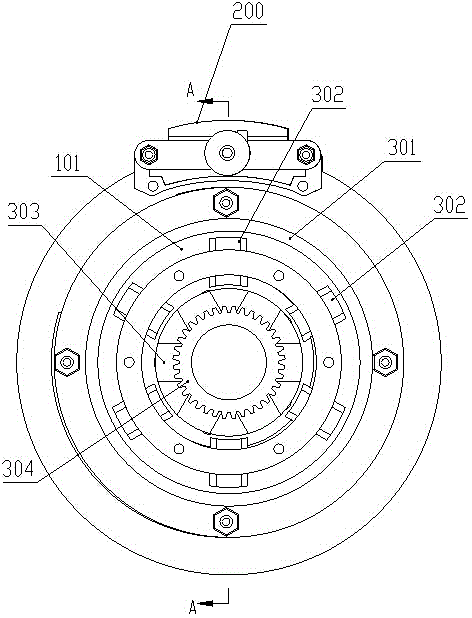

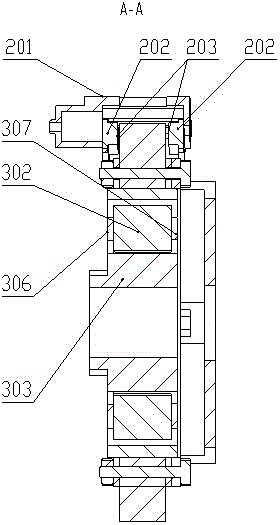

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: the outer disc inner magnetic disc brake of the present embodiment includes a brake disc 100 installed on the rotating shaft and performs frictional braking on the edge of the brake disc 100 The friction brake device 200 includes a caliper body 201, pistons 202 located on both sides of the brake disc 100 in the caliper body 201, and friction blocks 203 installed on the piston 202. The caliper body is provided with The oil passage connected with the piston, when the oil enters the oil passage, the two pistons 202 move to the brake disc 100 respectively and make the two friction blocks 203 press the brake disc 100, and the two sides of the rotating brake disc 100 are hydraulically It is braked by the friction resistance torque of the friction block 203.

[0031] In the middle of the brake disc 100, there is a circular hole 101 concentric with it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com