A silicon oil fan clutch with controllable separation speed

A clutch and silicone oil technology, which is applied in the field of silicone oil fan clutches, can solve the problems of fan clutch speed reduction, difficult processing, and high production costs, and achieve the effects of smooth meshing process, low production costs, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be further detailed below in conjunction with the accompanying drawings:

[0028] The core point of the present invention is that the system for different wind resistance can control the separation speed of the silicone oil fan clutch at an appropriate level, so that the negative pressure generated by the fan rotation under the separation condition can make the air flow overcome the wind resistance of the cooling system to reach the bimetal Around the temperature sensor, so that the bimetallic temperature sensor can sense the water temperature in the radiator 7 in time, and ultimately ensure that the engine works within a reasonable temperature range.

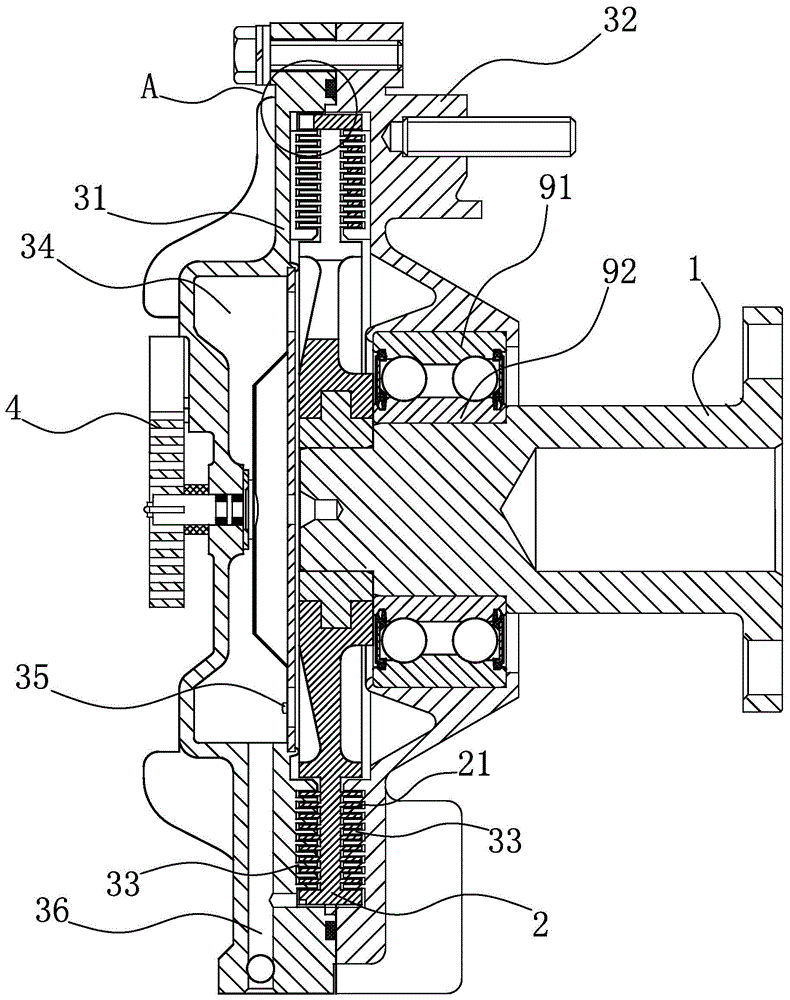

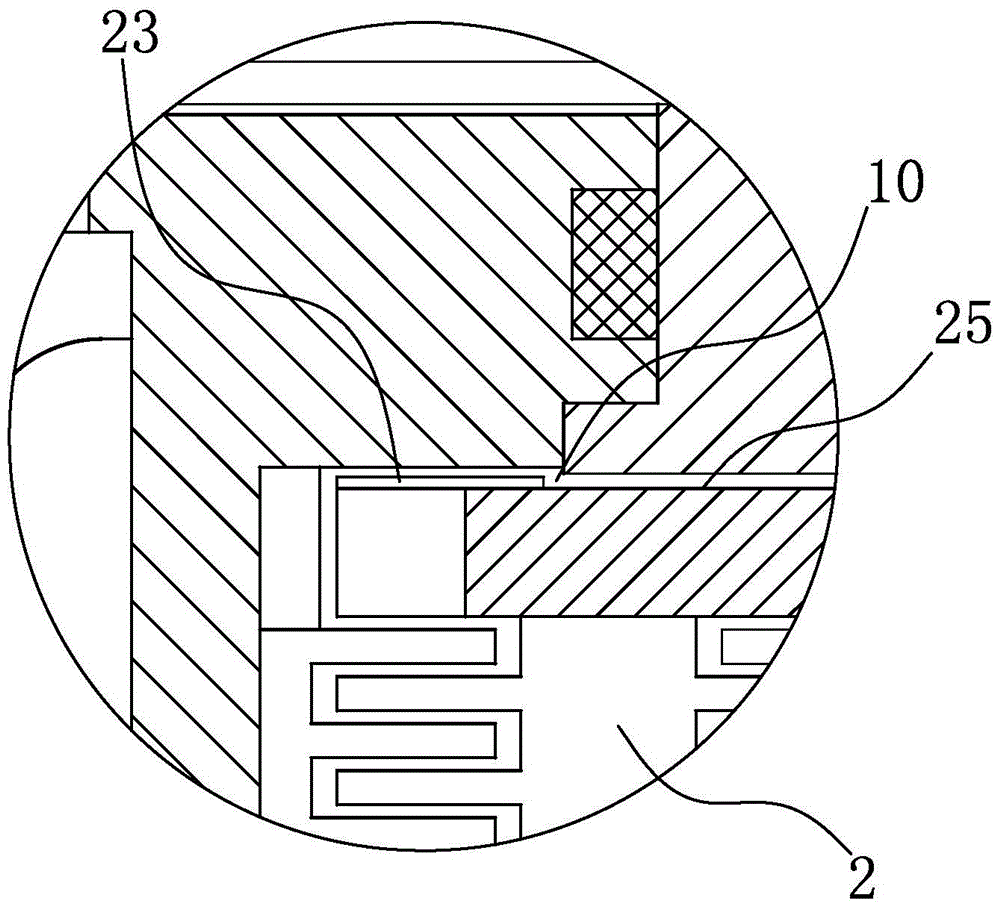

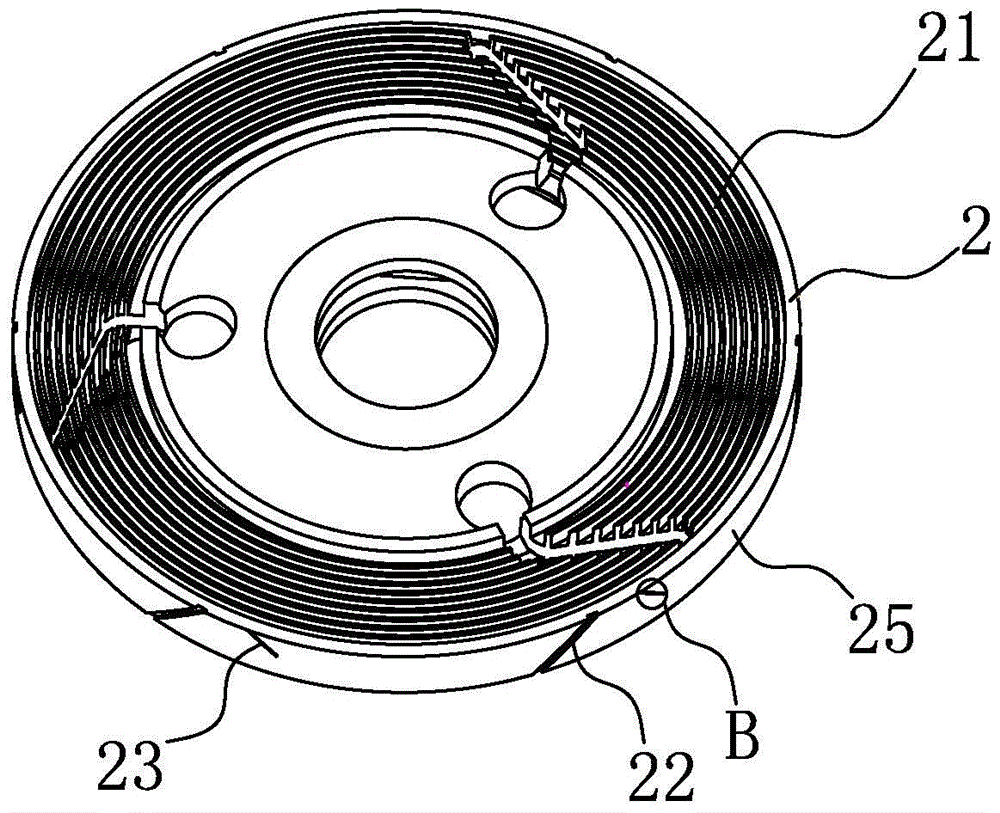

[0029] See Figure 1 to Figure 6 , The embodiment of the silicone oil fan clutch 100 with controllable separation speed provided in accordance with the present invention includes a sealed bearing, a housing mounted on the outer ring 91 of the sealed bearing, and a drive shaft mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com