Independent plinth construction method in narrow environment

A technology of independent column foundation and construction method, which is applied in the direction of foundation structure engineering, excavation, construction, etc., and can solve problems such as unsuitable use of load-bearing pile foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

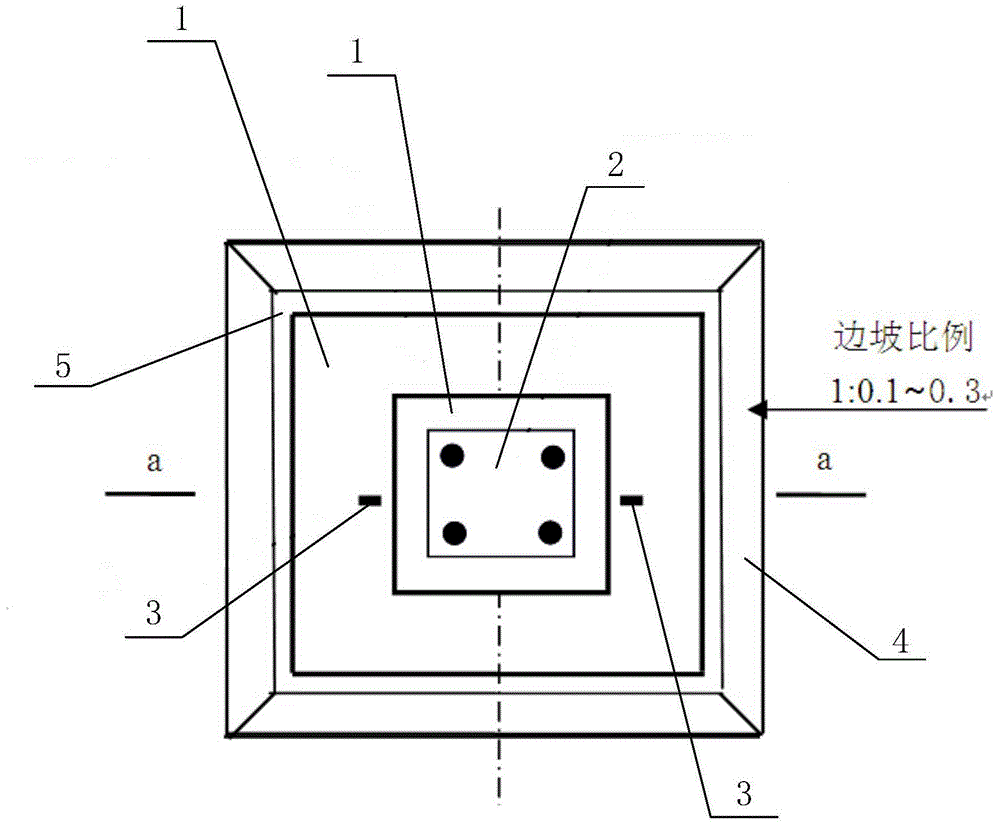

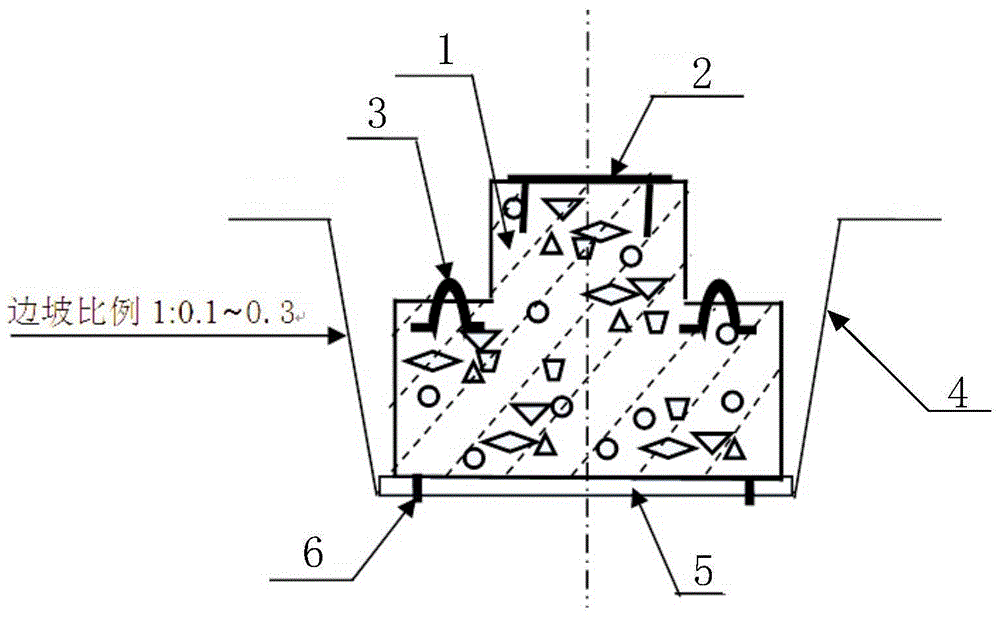

[0025] The following will combine figure 1 with figure 2 The independent column base construction method under the narrow environment provided by the present invention is described in detail, which is an optional embodiment of the present invention, and it can be considered that those skilled in the art can understand the It is revised and polished.

[0026] Please refer to figure 1 , this embodiment provides a construction method for an independent column base in a narrow environment, including the following steps:

[0027] S1: According to the required volume, mass, cross-sectional size and structural form, determine the number of different independent column bases, the volume and quality of each independent column base, and then determine the position of its lifting point and the material and diameter of the ring reinforcement;

[0028] S2: Pouring each independent column foundation according to the determination result of step S1, and assembling the lifting ring 3 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com