Production process method for novel crop straw environment-friendly material

A technology of crop straw and production process, applied in textiles and papermaking, water/steam pretreatment, etc., can solve problems such as difficult and effective treatment, environmental pollution, etc., and achieve the effects of protecting the environment, high pulp strength, and improving quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

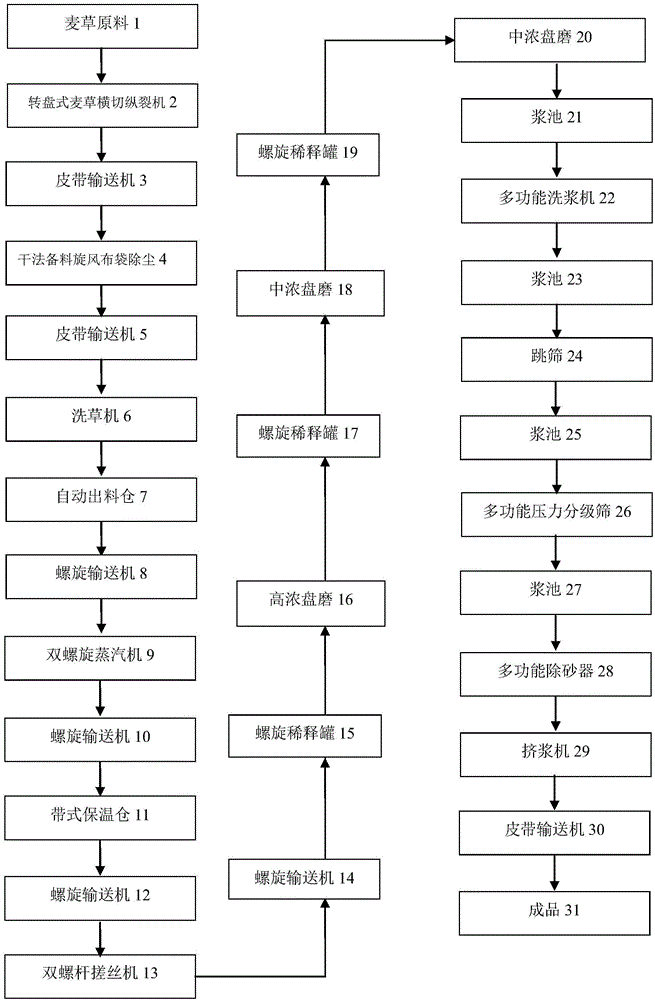

[0031] like figure 1 As shown, the production process flow chart of the crop straw environmental protection new material of the present invention: take the raw material wheat straw as an example:

[0032] A production process method for crop straw environmentally friendly new materials, the method steps comprising:

[0033] (A), the wheat straw raw material 1 is crushed, wire-drawn and disintegrated by the rotary disc type wheat straw cross-cutting and slitting machine 2;

[0034] (B), the wheat straw raw material 1 is sent into the dry preparation cyclone bag dedusting 4 by the belt conveyor 3, and wind power dust removal is carried out to remove silt, impurities etc. in the wheat straw raw material; then, the wheat straw raw material is passed through the belt conveyor 5 1 into the grass washing machine 6 to remove impurities mixed in the wheat straw raw material;

[0035] (C), the wheat straw raw material 1 washed by the grass washing machine 6 is sent into the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com