Formula and preparation method of high temperature emulsified acid

A high-temperature emulsification and acid emulsification technology, applied in the field of emulsified acid, can solve the problems of uneven acid release, uneven demulsification, poor stability, etc., and achieve the effect of no pitting corrosion, easy monitoring of emulsion quality, and increased strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

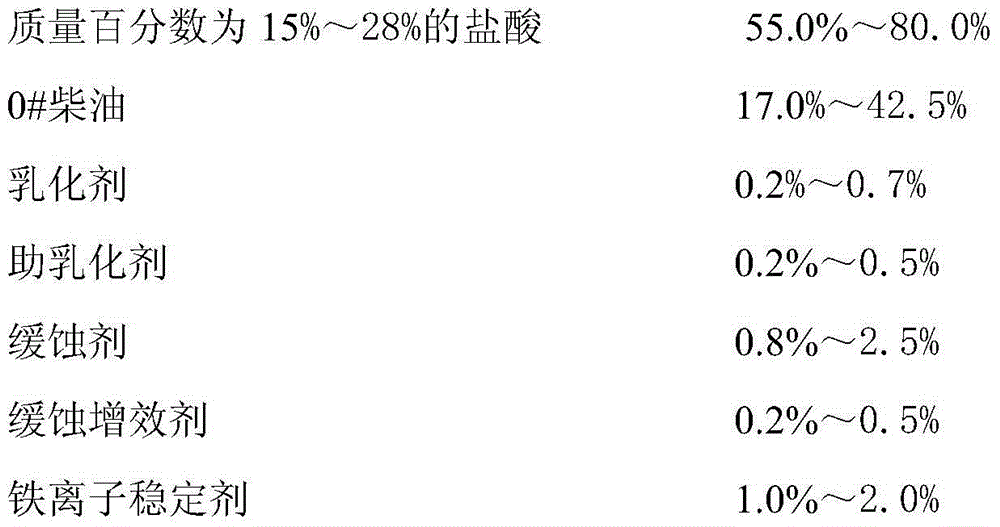

Method used

Image

Examples

Embodiment 1

[0018] Prepare 300mL of acid phase hydrochloric acid with a concentration of 15% and emulsified acid with a volume ratio of 55:45 to acid oil in the room.

[0019] Acid phase preparation: Measure 76mL of industrial hydrochloric acid with a mass percentage of 31%, add 1.65g of corrosion inhibitor and 0.33g of corrosion inhibitor synergist, stir evenly, then add 1.65g of iron ion stabilizer, stir evenly, and dilute to volume with tap water to 165mL.

[0020] Oil phase preparation: Measure 90mL of 0# diesel oil, add 1.5g of emulsifier and 0.9g of co-emulsifier, dissolve evenly, and dilute to 135mL with 0# diesel oil.

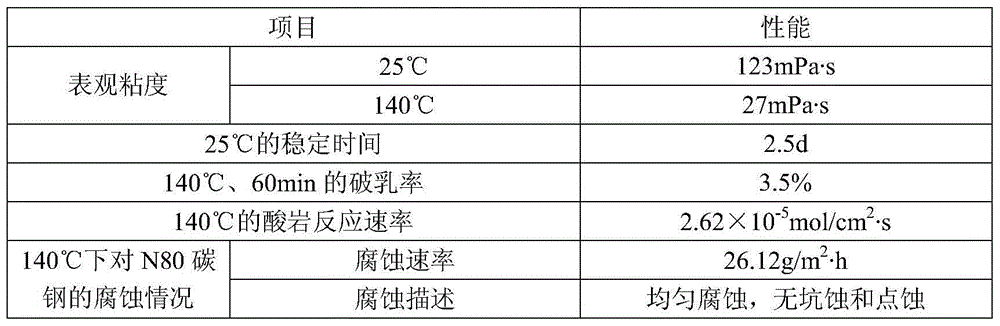

[0021] Preparation of emulsified acid: Pour the prepared oil phase into the volume cup of the agitator, adjust the stirring speed to 3000rpm, slowly pour the acid phase into the volume cup of the agitator under stirring conditions, continue stirring for 5min, and measure it with a conductivity tester Conductivity, the conductivity is 0S / m, indicating that the emul...

Embodiment 2

[0026] Prepare 300mL of acid phase hydrochloric acid with a concentration of 15% and an emulsified acid with a volume ratio of acid to oil of 65:35 in the room.

[0027] Acid phase preparation: Measure 88mL of industrial hydrochloric acid with a mass percentage of 31%, add 1.95g of corrosion inhibitor and 0.4g of corrosion inhibitor synergist, stir evenly, then add 1.95g of iron ion stabilizer, stir evenly, and dilute to volume with tap water to 195mL.

[0028] Oil phase preparation: Measure 90mL of 0# diesel oil, add 1.5g of emulsifier and 0.9g of co-emulsifier, dissolve evenly, and dilute to 105mL with 0# diesel oil.

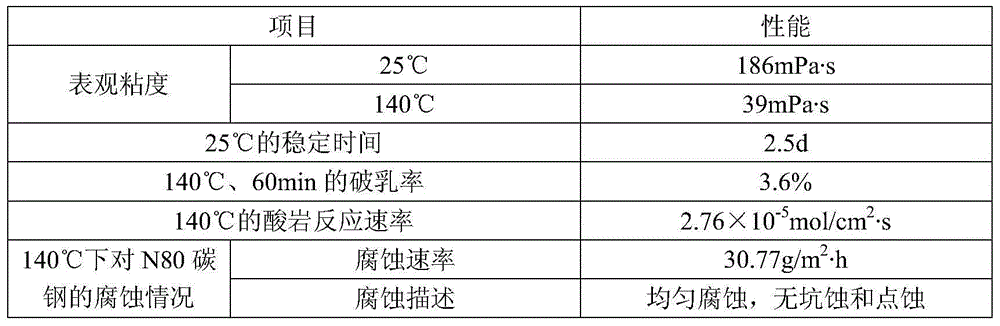

[0029] Preparation of emulsified acid: Pour the prepared oil phase into the volume cup of the agitator, adjust the stirring speed to 3000rpm, slowly pour the acid phase into the volume cup of the agitator under stirring conditions, continue stirring for 5min, and measure it with a conductivity tester Conductivity, the conductivity is 0S / m, indicating that the...

Embodiment 3

[0034] Prepare 300mL of acid phase hydrochloric acid with a concentration of 15% and emulsified acid with an acid-oil volume ratio of 80:20 in the room.

[0035]Acid phase preparation: Measure 112mL of industrial hydrochloric acid with a mass percentage of 31%, add 2.4g of corrosion inhibitor and 0.5g of corrosion inhibitor synergist, stir evenly, then add 2.4g of iron ion stabilizer, stir evenly, and dilute to volume with tap water to 240mL.

[0036] Oil phase preparation: Measure 40mL of 0# diesel oil, add 1.5g of emulsifier and 0.9g of co-emulsifier, dissolve evenly, and dilute to 60mL with 0# diesel oil.

[0037] Preparation of emulsified acid: Pour the prepared oil phase into the volume cup of the agitator, adjust the stirring speed to 3000rpm, slowly pour the acid phase into the volume cup of the agitator under stirring conditions, continue stirring for 5min, and measure it with a conductivity tester Conductivity, the conductivity is 0S / m, indicating that the emulsified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com