B1-grade flame-retardant polyurethane rigid foam used for continuous line production as well as preparation method and usage thereof

A rigid foam and polyurethane technology, which is applied in the field of manufacturing foam insulation materials for construction, can solve the problems of poor foam fluidity, large concentrated heat release, slow foam curing, etc. Good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following examples will further illustrate the method provided by the present invention, but the present invention is not limited to the listed examples, and should also include any other known changes within the claimed scope of the present invention.

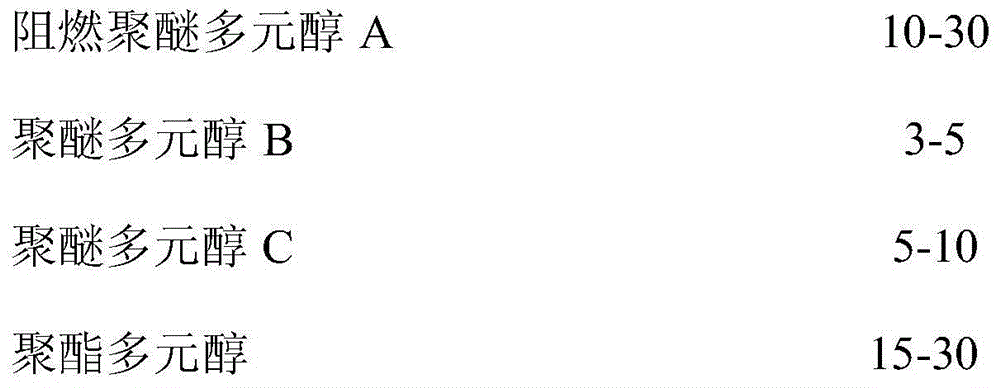

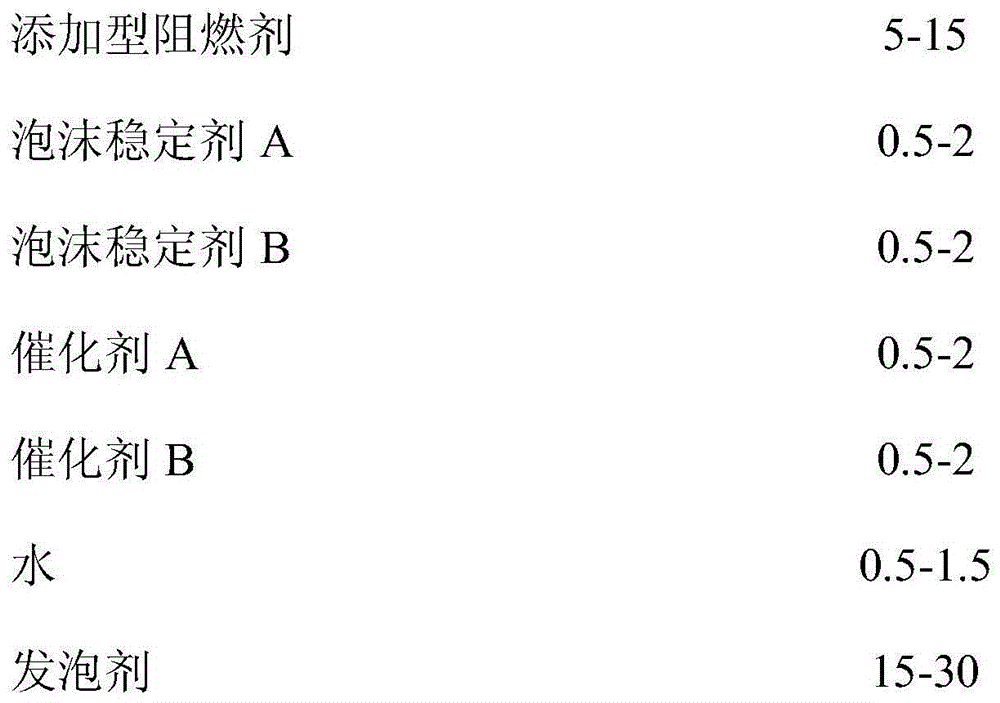

[0047] Raw material and equipment involved in the embodiment:

[0048] High-pressure foaming machine: German HENNECK machine,

[0049] Flame-retardant polyether polyol A: FR130 (Wanhua Chemical (Ningbo) Rongwei Polyurethane Co., Ltd.)

[0050] Polyether polyol B: PEG200, PEG400, PEG600 (Jiangsu Haian Petrochemical Plant),

[0051] Polyether polyol C: R6245 (Wanhua Chemical (Ningbo) Rongwei Polyurethane Co., Ltd.), H6020 (Nanjing Hongbaoli Co., Ltd.), SA-460 (Shandong Bluestar Dongda Chemical Co., Ltd.)

[0052] Additive flame retardant: a mixture of tris(2-chloropropyl) phosphate and triethyl phosphate with a mass ratio of 60:40.

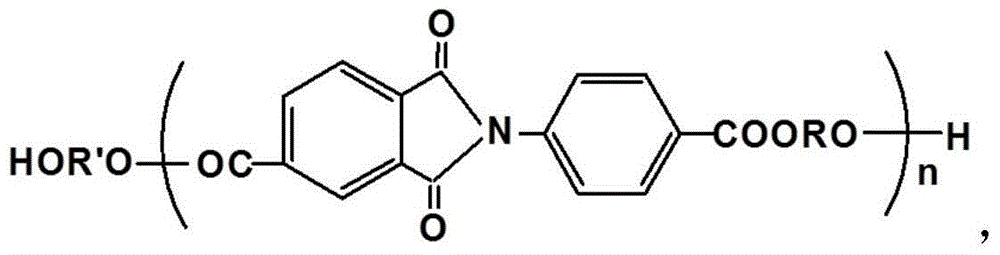

[0053] Polyester polyol 1:

[0054] Add trimellitic anhydride, p-aminobenzoic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com