A high-furrow enhanced surface flow constructed wetland system and its operation method

A constructed wetland system and Takakuro technology, applied in the field of water treatment, can solve problems such as low water purification efficiency and turbidity of effluent, and achieve the effects of low investment and operating costs, increased diversity, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

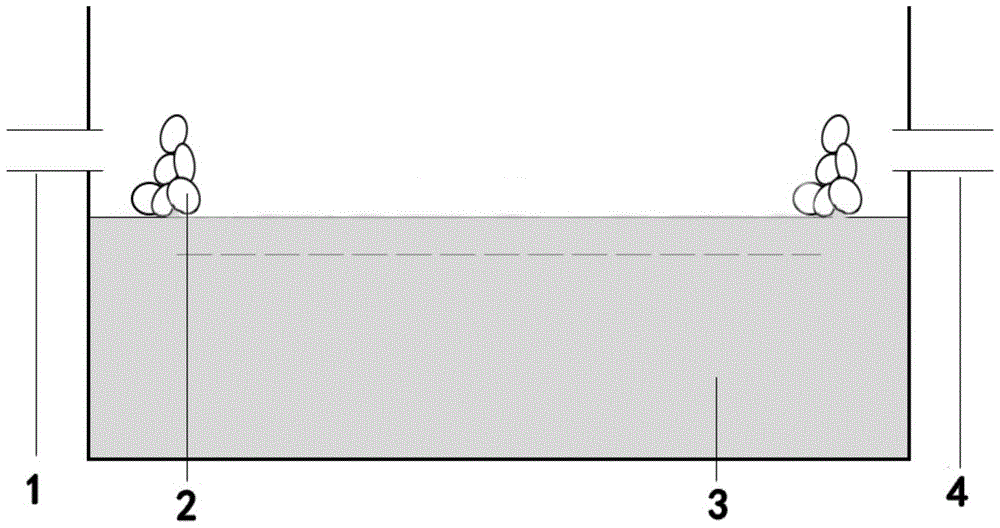

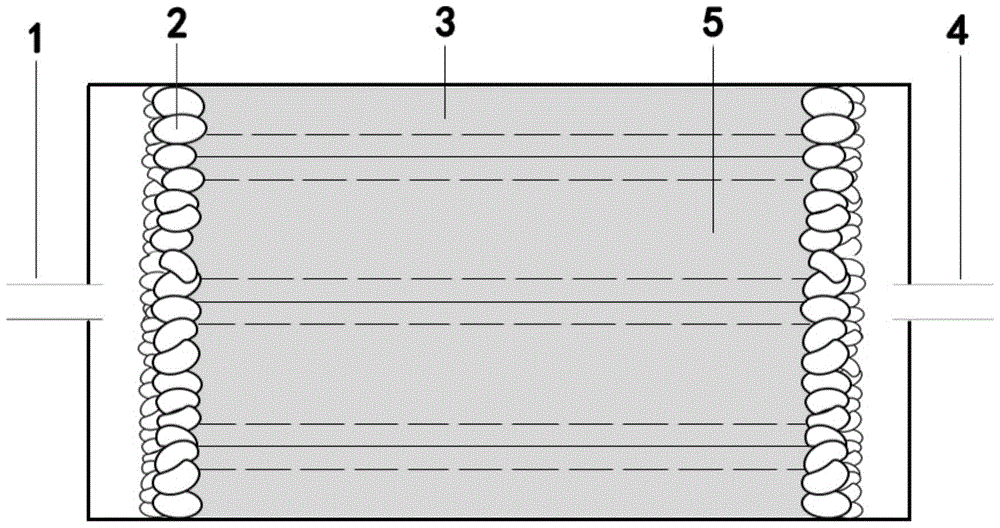

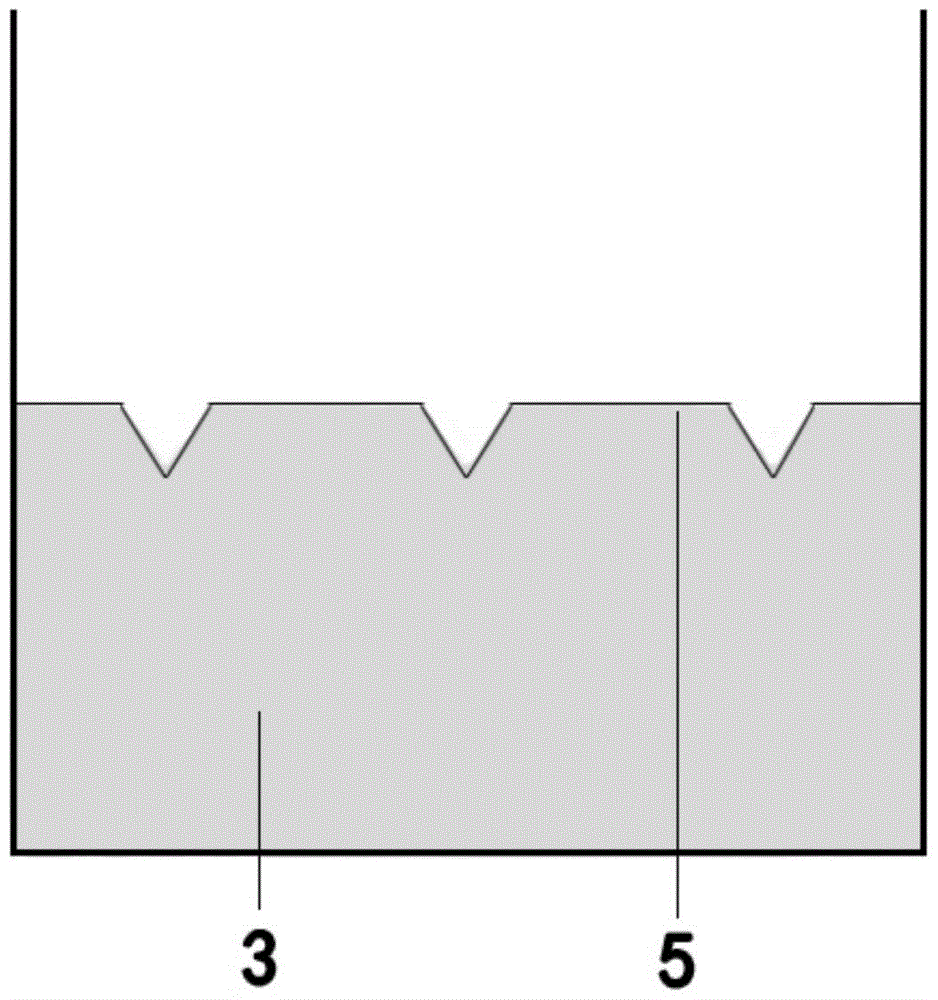

[0027] The Takakuro type surface flow artificial wetland system of the present invention has a structure such as figure 1 , figure 2 and image 3 shown. It includes water inlet pipe 1, water distribution weir 2, bed body 3, water outlet weir and water outlet pipe 4. The bed body 3 is made of concrete and is rectangular in shape with an aspect ratio of 1.8-2.0:1. The length and width are determined according to actual conditions, and the depth is 1.2-1.3m. The bed body 3 is filled with matrix (light loam and medium loam) and compacted to a filling depth of 0.6-0.7m. A water inlet pipe 1 and a water outlet pipe 4 are respectively arranged on both sides of the bed body 3 in the length direction at about 0.3 m above the substrate surface. The two sides of the length direction of the bed body 3 are respectively provided with a water distribution weir 2 and an outlet weir, both of which are triangular weirs with a height of 0.4-0.45m piled up by gravel or stones with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com