Method for manufacturing hat eye brow and eye brow manufactured by adopting method

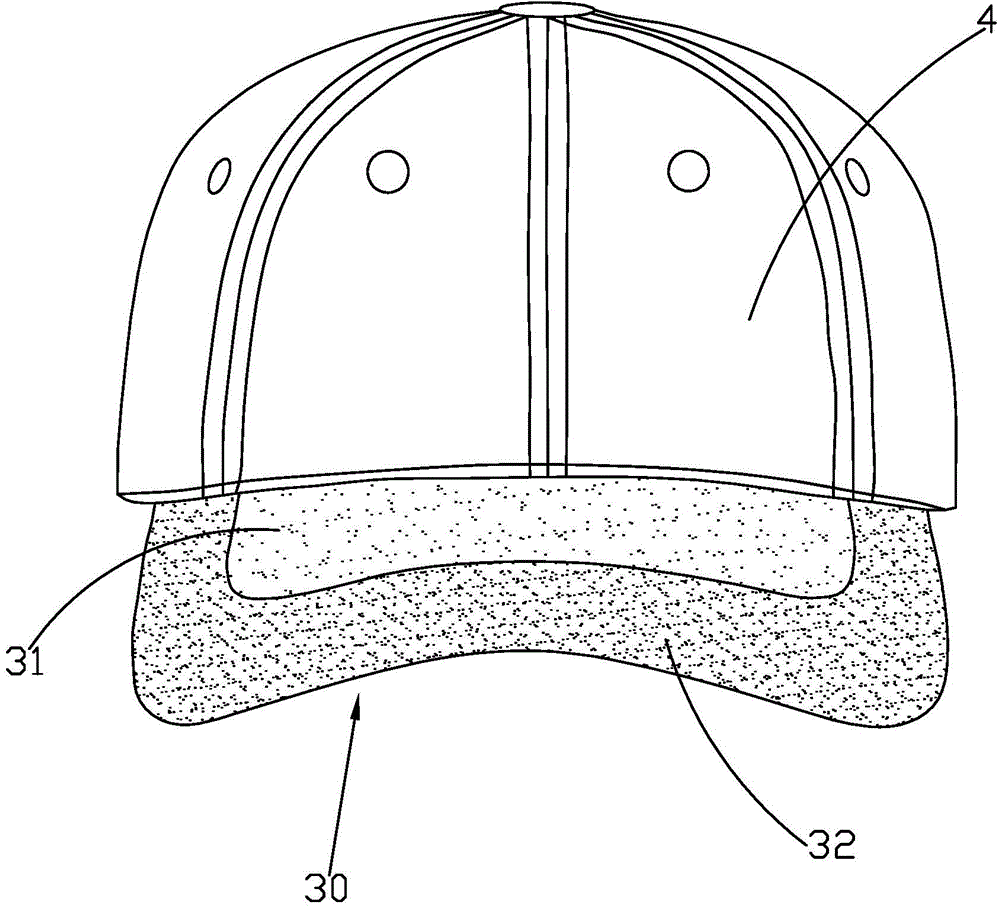

A technology of brow boards and hats, which is applied in the field of making hat brow boards, which can solve problems such as easy sagging, damaged skin on the head, inconvenient walking or observation, etc., and achieve a good-looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

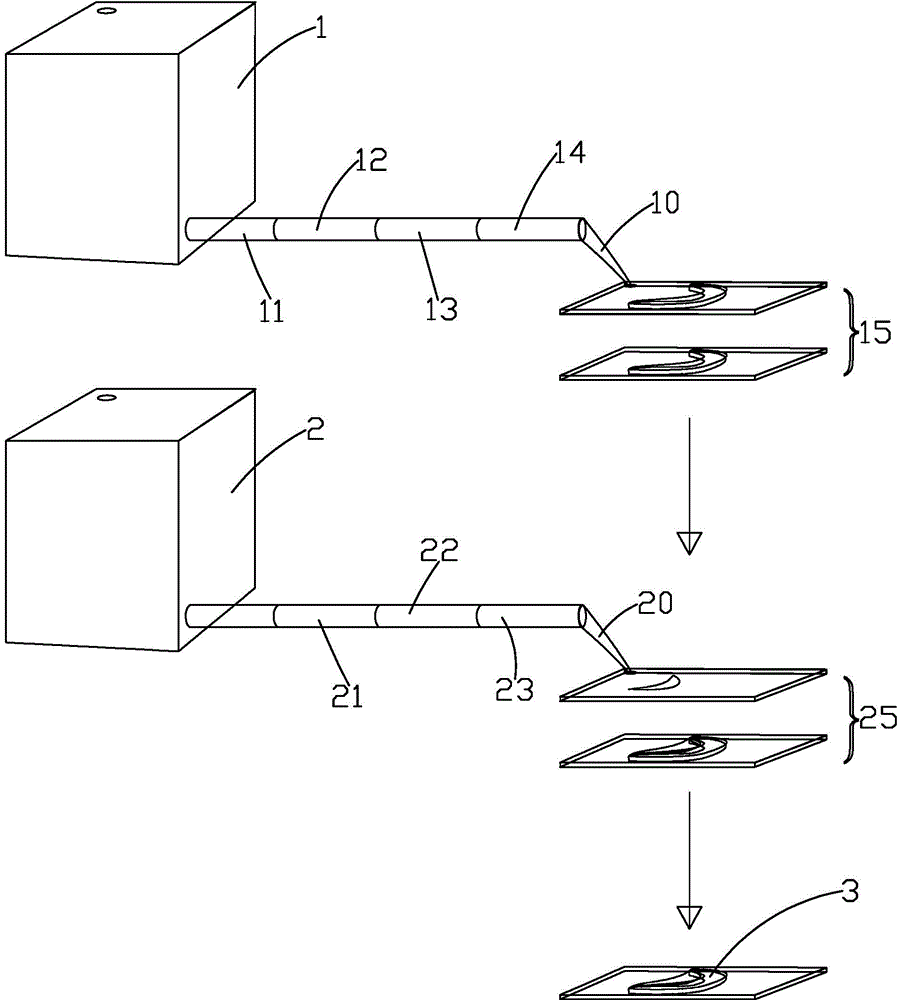

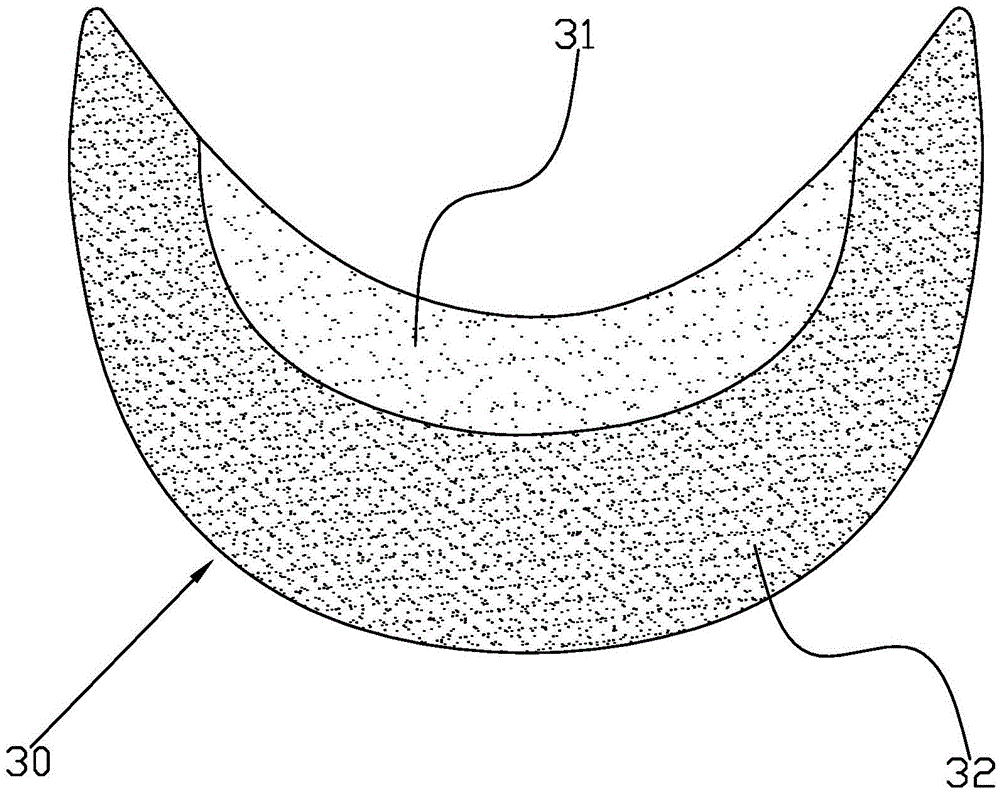

[0034] A method for making a hat brow, comprising the following steps:

[0035] Prepare the mold and molding materials, first prepare the first injection mold and the second injection mold, then install the first injection mold and the second injection mold on the injection molding machine, and finally prepare the molding materials for injection molding, here, as this In a preferred embodiment of the invention, the above-mentioned molding material ready for injection molding is preferably PE;

[0036] 2) One-time injection molding, firstly heat the molding material and raise the temperature of the molding material to 140°C, at this time the molding material melts, and then inject the melted molding material into the first injection mold through the injection molding machine, so as to form the first Parts, in the present invention, before the injection molding machine injects the molten molding material into the first injection mold, the injection molding machine needs t...

Embodiment 2

[0039] A method for making a hat brow, comprising the following steps:

[0040] 1) Prepare the mold and molding materials, first prepare the first injection mold and the second injection mold, then install the first injection mold and the second injection mold on the injection molding machine, and finally prepare the molding materials for injection molding, here, As a preferred embodiment of the present invention, the above-mentioned molding material ready for injection molding is preferably PE;

[0041]2) In one injection molding, first heat the molding material and raise the temperature of the molding material to 150°C, at this time the molding material melts, and then inject the melted molding material into the first injection mold through the injection molding machine, so as to form the first Parts, in the present invention, before the injection molding machine injects the molten molding material into the first injection mold, the injection molding machine needs to continu...

Embodiment 3

[0044] A method for making a hat brow, comprising the following steps:

[0045] 1) Prepare the mold and molding materials, first prepare the first injection mold and the second injection mold, then install the first injection mold and the second injection mold on the injection molding machine, and finally prepare the molding materials for injection molding, here, As a preferred embodiment of the present invention, the above-mentioned molding material ready for injection molding is preferably PE;

[0046] 2) One-time injection molding, first heat the molding material and raise the temperature of the molding material to 160°C, at this time the molding material melts, and then inject the melted molding material into the first injection mold through the injection molding machine, so as to form the first Parts, in the present invention, before the injection molding machine injects the molten molding material into the first injection mold, the injection molding machine needs to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com