Steel rail grinding machine

A grinding machine and grinding mechanism technology, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc., can solve problems such as inaccurate flaw detection results, and achieve the effects of ensuring health and improving grinding speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

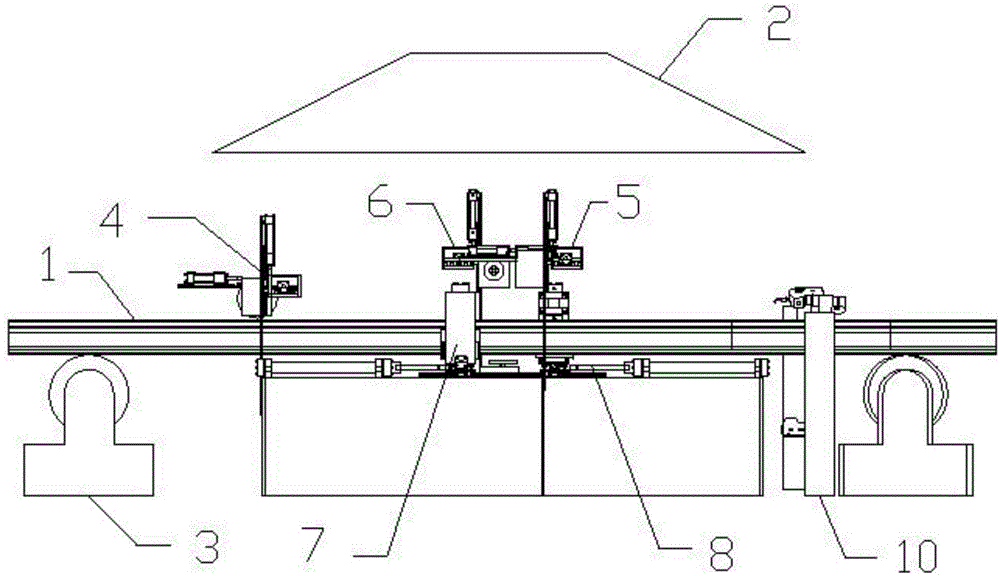

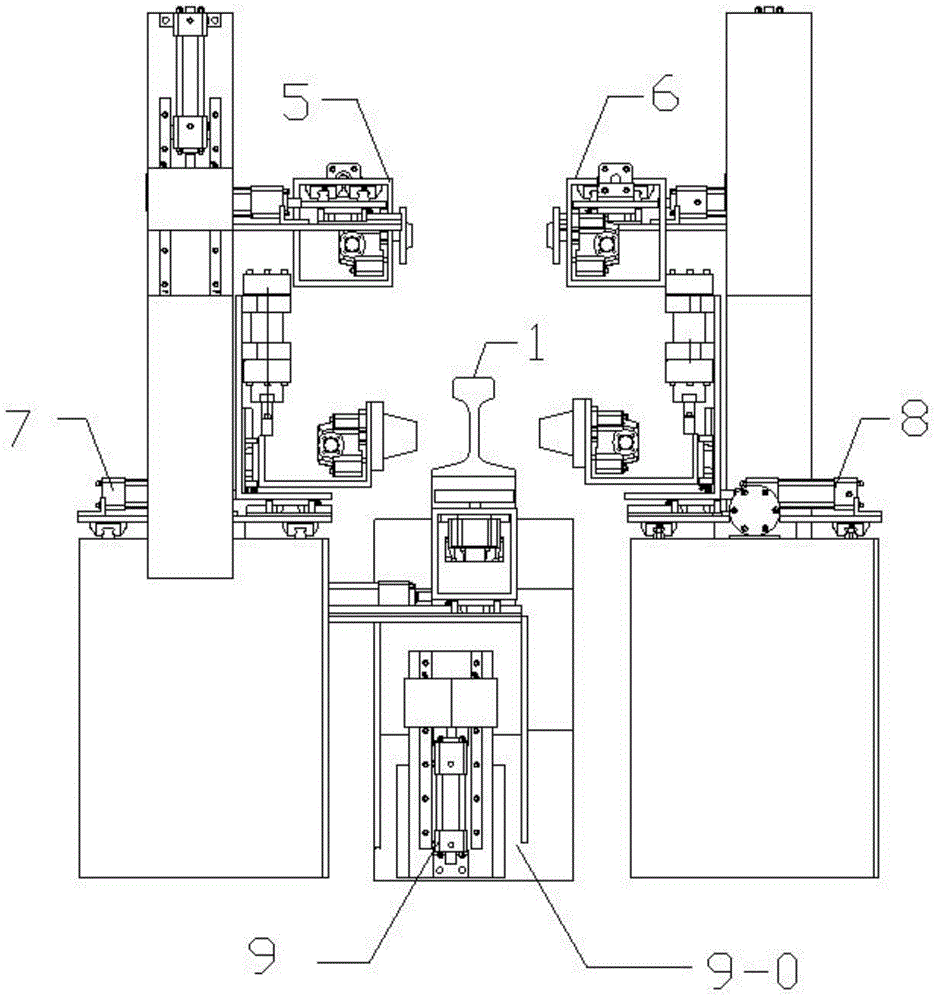

[0061] Example 1: A rail grinding machine, its structure reference Figure 2-4 Shown include:

[0062] Rail top surface grinding mechanism 4, rail head side grinding mechanism, rail triangle grinding mechanism, rail bottom grinding mechanism 9, running line drum 3 and dust cover 2, rail 1 is caught by the rail while sliding on the running line drum 3 The top surface grinding mechanism 4, the rail head grinding mechanism, the rail triangle grinding mechanism and the rail bottom grinding mechanism 9 are ground, and the dust generated during the grinding process is sucked away by the dust hood 2;

[0063] The traveling line roller 3 includes a support 3-1, and a roller 3-2 is installed on the support 3-1.

[0064] reference Figure 7 As shown, the rail bottom grinding mechanism 9 includes a central base 9-0, a backing plate 9-1 is fixedly connected to the central base 9-0, and a Z-direction oil cylinder 9-2 and Z-direction guide rail 9-3, Z-direction oil cylinder 9-2 drives Z-direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com