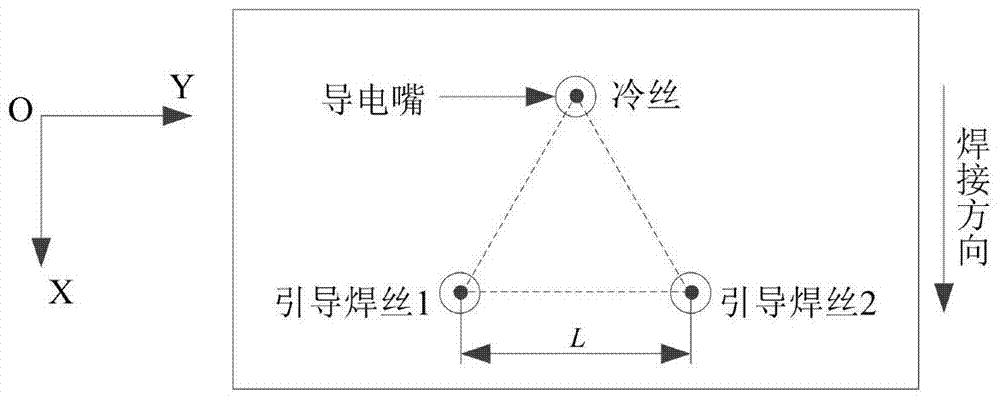

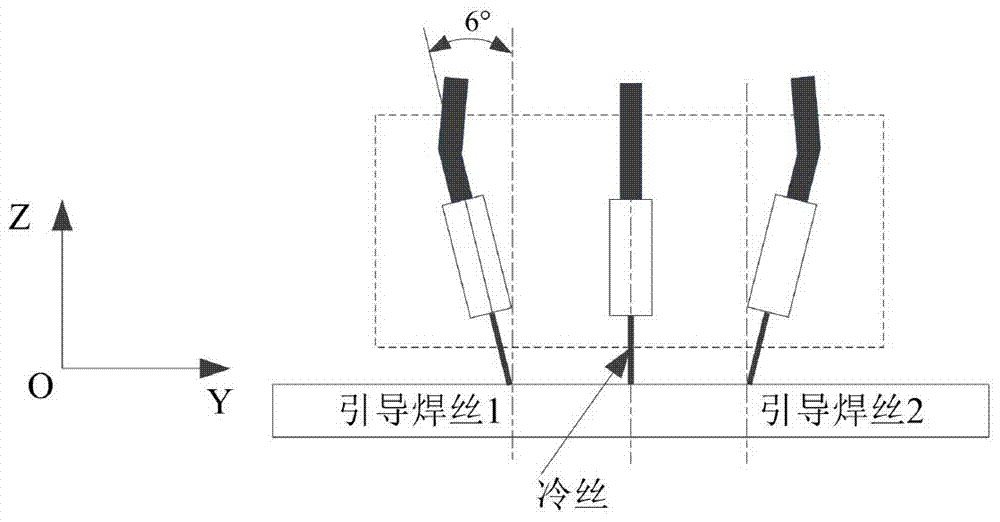

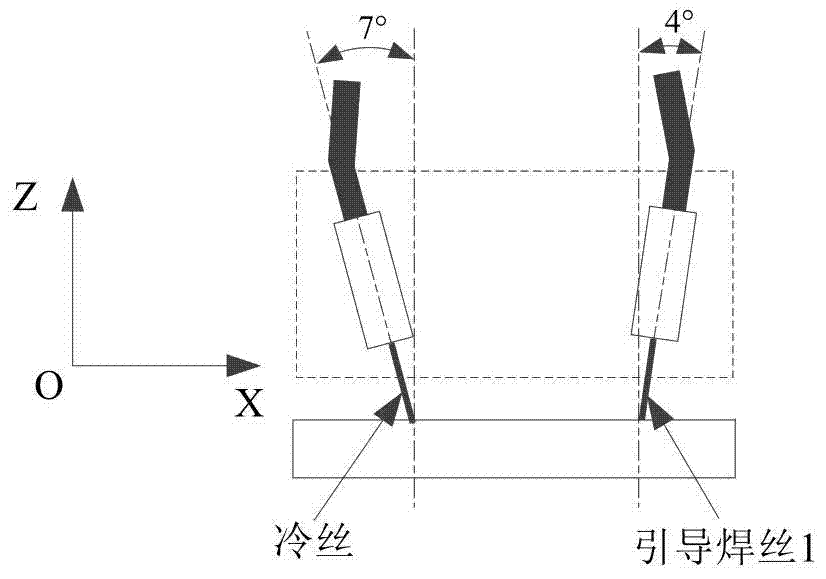

Three-wire welding torch, welding system and method for double-arc and cold wire pulse hybrid welding

A hybrid welding and double arc technology, applied in arc welding equipment, welding equipment, devices supporting electrode clamps, etc., can solve problems such as small welding parameters, weld defects, etc., to reduce the probability of interference between two arcs, reduce severe The effect of tumbling and welding efficiency at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] Implementation method: adopt the welding method of double arc and cold wire pulse hybrid welding, and implement the plate surfacing test. The specific implementation steps are as follows:

[0060] Basic steps of welding process:

[0061] (1) According to Figure 4 Connect the equipment (including the main system equipment and acquisition system equipment) at the position shown, and access the power supply with a power frequency of 50Hz;

[0062] (2) Adjust the working mode of the two Pulse MIG-350, and adjust the pulse working mode of the two welding machines to one master and one slave through the front control panel, that is, the master welder guides the slave welder to send pulse signals;

[0063] (3) Adjust the preset current and voltage of the two welding machines, the preset current range: 80-220A, the preset voltage range: 18-32V;

[0064] (4) Adjust the corresponding pulse waveform input of the two welding machines, and the pulse waveform output that can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com