Portable hydraulic multipurpose punching machine

A multi-purpose and portable technology, applied in the field of electric machinery processing facilities, can solve the problems of laborious, punching can only be processed by drilling machine or hand electric drill, and the accuracy of processed parts is not high, so as to ensure the installation process and quality and reduce time. and labor intensity, the effect of improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

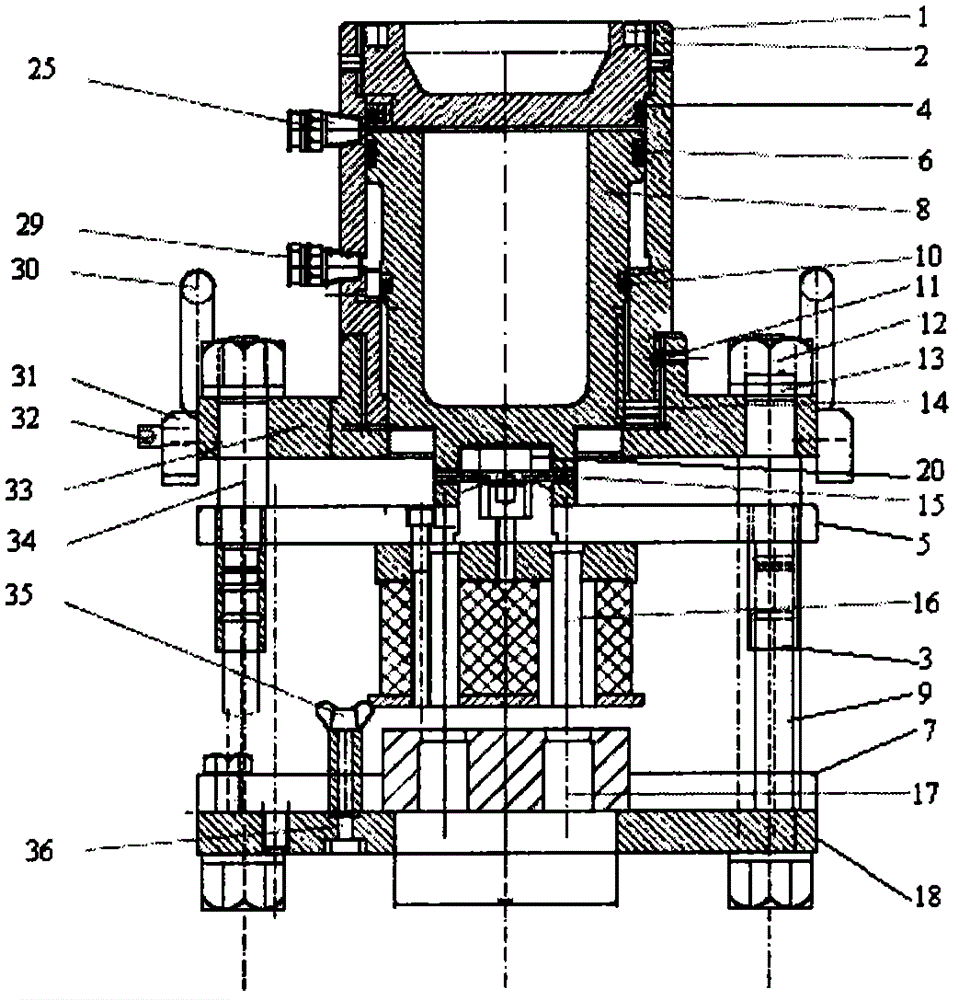

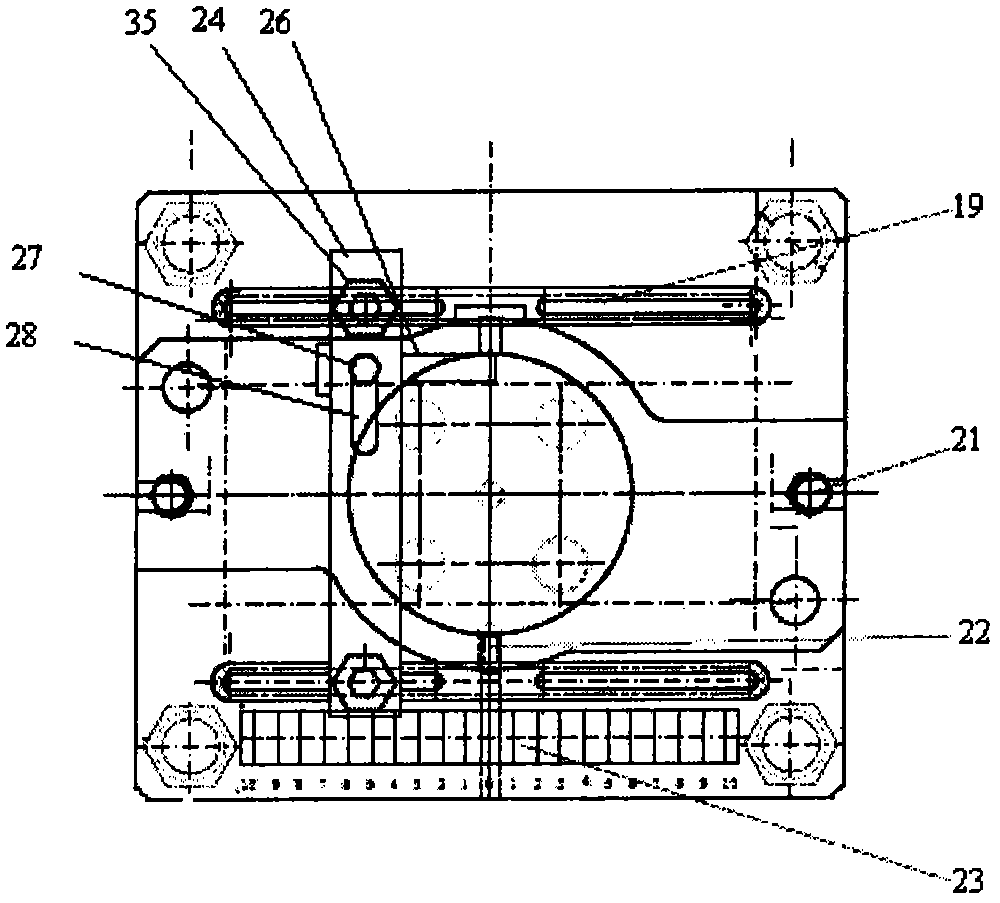

[0010] As shown in the figure, the portable hydraulic multipurpose punching machine is composed of components such as a frame, a hydraulic system, and a punching device. 1. The handle mounting block 31 is formed, and the column 34 is fixedly installed on the four corners of the base 18 and the oil cylinder seat 33 by the nut 12 . The hydraulic system is composed of a bottom cover 1, an oil cylinder 2, O-rings 4, 6, 10, a piston 8, a piston adapter shaft 20, a male joint 25 and a female joint 29, and the input pressure is 700KG / cm 2 , the maximum thrust of the piston is 100T, and the effective stroke is 40mm. Oil cylinder 2 is installed on the frame oil cylinder seat 33 by fixing screw 11, and the lower end of the piston extends out of the round hole provided in the center of oil cylinder seat 33, connects punching device male die seat 5 through piston transfer shaft 20, and sets and installs on the frame base 18. The punching device female mold base 7 of the punching female m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com