Method for straightening bent square billet

A technology for straightening and billet, which is applied in the field of straightening and bending billet, can solve the problems of high production cost and billet waste, achieve the effect of reducing the quantity and improving the satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

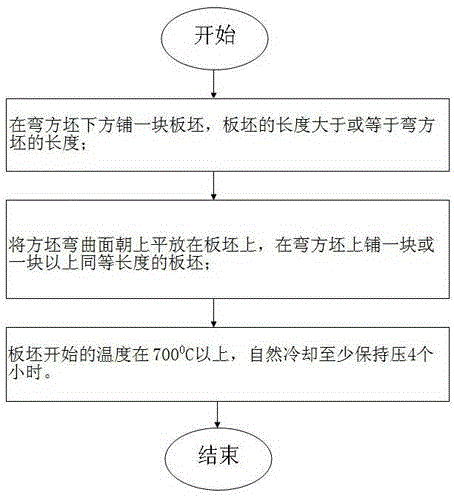

[0017] Such as figure 1 and figure 2 Shown, a kind of method for straightening curved billet comprises the following steps:

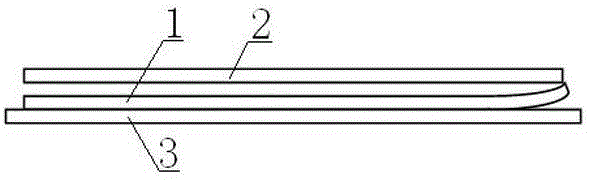

[0018] 1) Laying a slab 3 under the bent billet 1, the length of the slab 3 is greater than or equal to the length of the bent billet 1;

[0019] 2) Place the curved billet 1 flat on the slab 3, and spread one or more slabs 2 of the same length on the curved billet 1;

[0020] 3) The starting temperature of the slab is 700 0 Above C, naturally cool and keep the pressure for at least 4 hours.

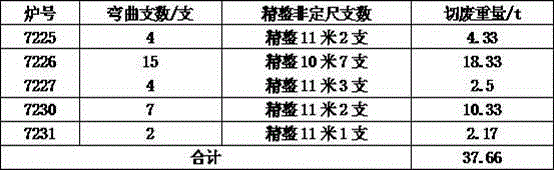

[0021] Table 1 and Table 2 show the bending billet and finishing conditions, and Table 3 shows the situation of using the present invention to process the bending billet. (The billet produced without furnace number meets the quality requirements)

[0022] Table 1 9 furnaces of 35CrMo produced on July 16, 2013

[0023]

[0024] Table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com