Ultrasonic wave emitting circuit

A transmitting circuit and ultrasonic technology, applied in the field of ultrasonic transmission, can solve the problems of not steep pulse front, complex circuit structure and high cost, and achieve the effects of wide application range, simple circuit structure and strong load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the technical solution of the ultrasonic transmitting circuit of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] The invention relates to an ultrasonic transmitting circuit, which is suitable for the application system of the ultrasonic probe of the separate transceiver and the ultrasonic probe of the same body of the transceiver.

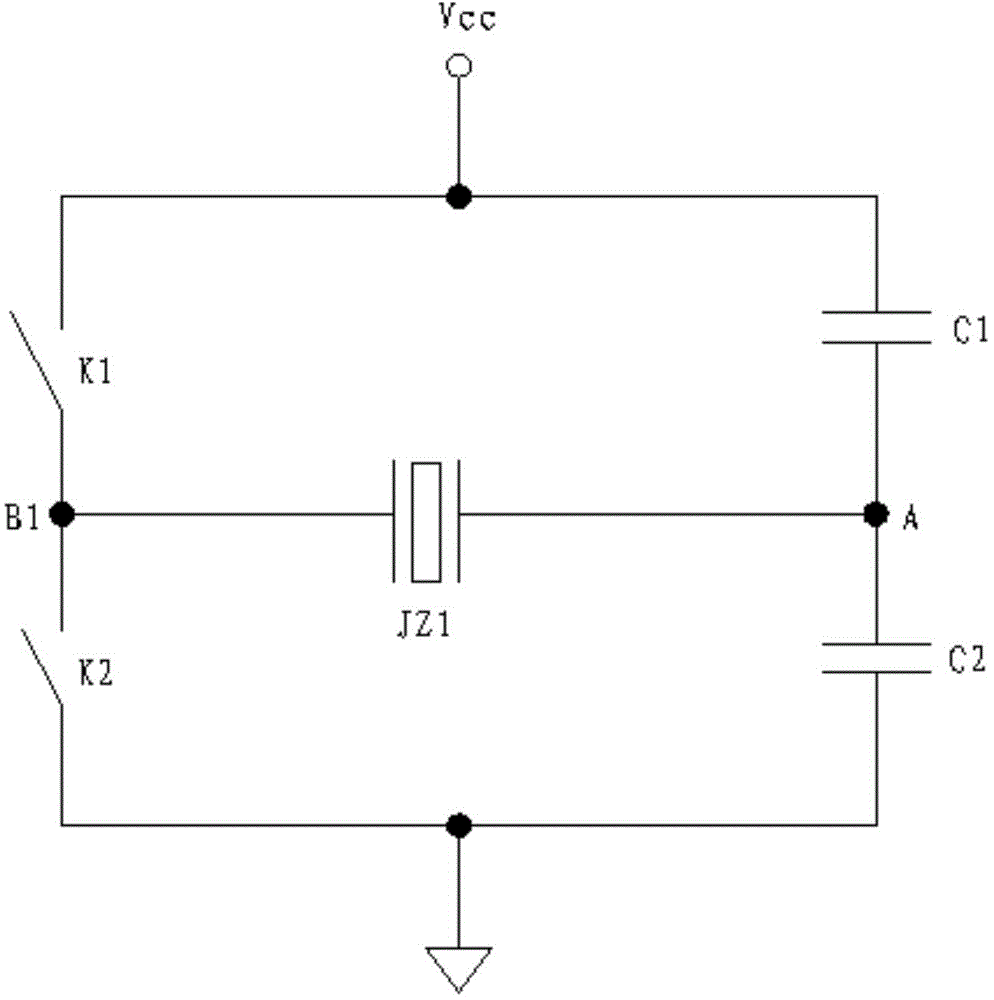

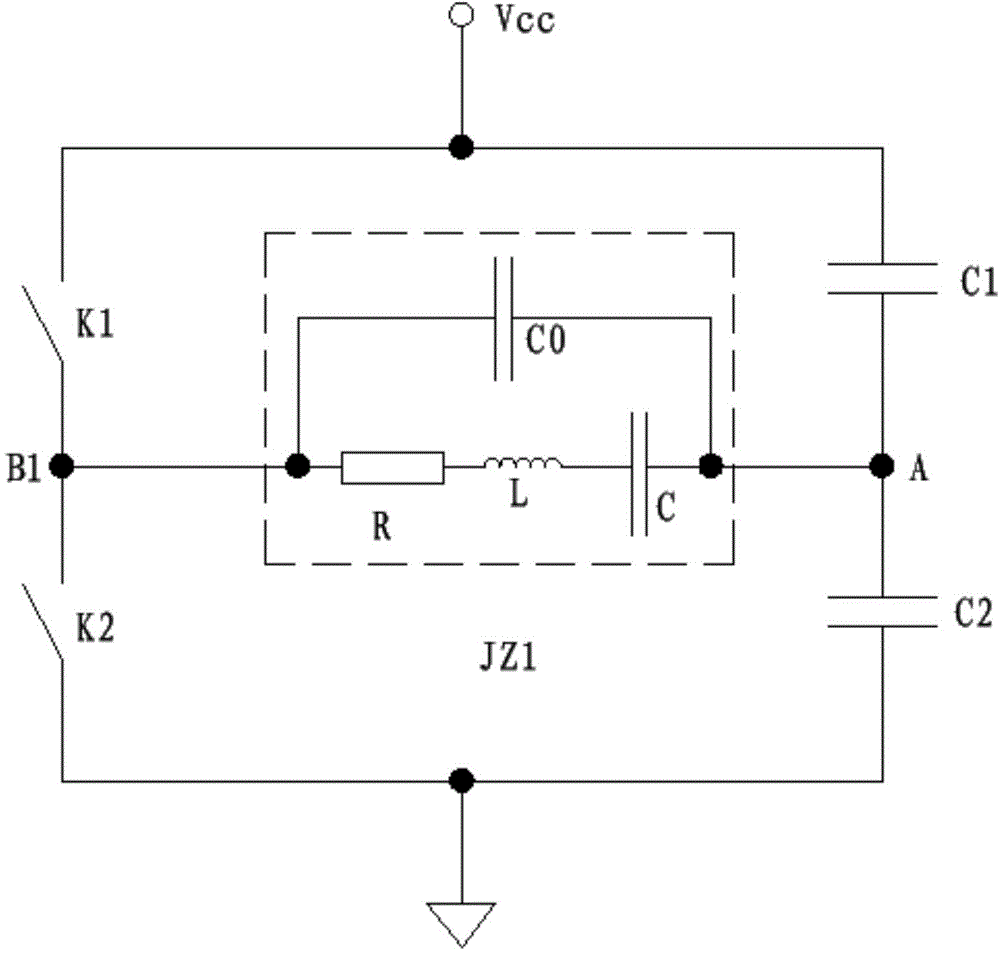

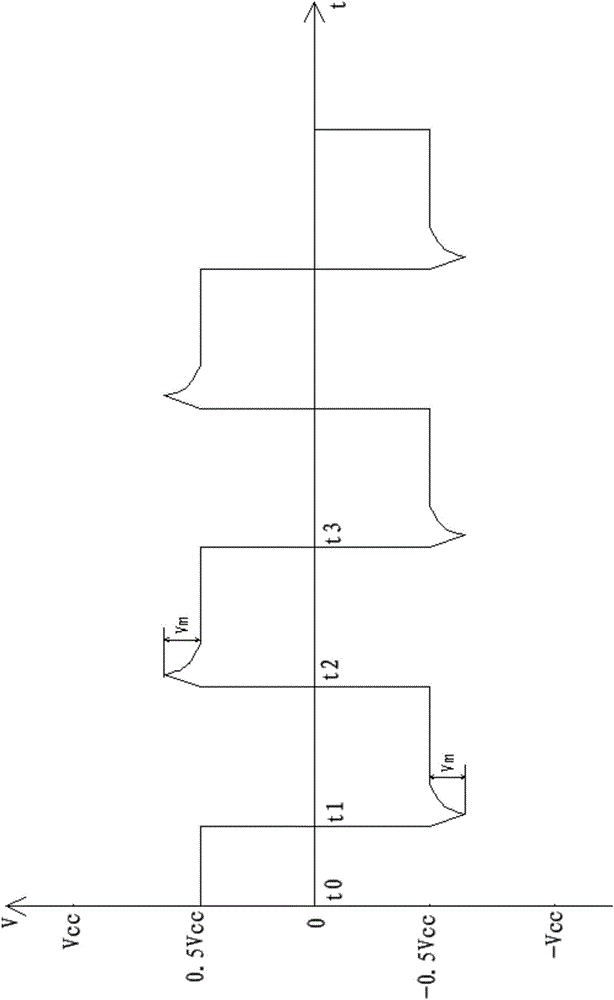

[0030] as attached figure 1 And attached figure 2 As shown, one end of capacitor C1 and electronic switch K1 is connected to the power supply Vcc, one end of capacitor C2 and electronic switch K2 is grounded (reference potential), the other end of capacitor C1 is connected to the other end of capacitor C2, and its connection point is node A. The other end of the switch K1 is connected to the other end of the electronic switch K2, and its connection point is node B1, and the two ends of the ultrasonic probe JZ1 are respectively connected to node A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com