Copper-lead mixed concentrate flotation separation inhibitor and its preparation method and beneficiation method

A separation method and inhibitor technology, applied in flotation, solid separation, etc., can solve problems such as environmental hazards, corrosiveness of equipment and workshops, and unstable operation, and achieve huge application prospects, environmentally friendly production processes, and simplified process requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

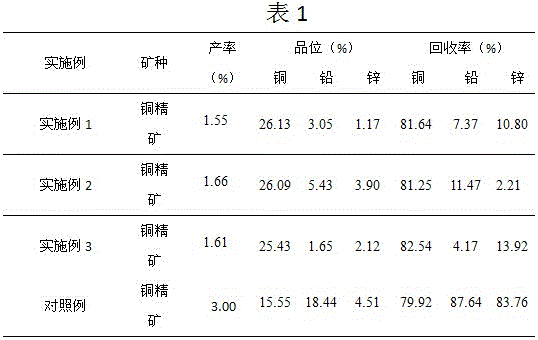

Examples

Embodiment 1

[0030] 1. In parts by weight, weigh 30 parts of phthalic acid, 15 parts of thiosalicylic acid, 5 parts of tannin extract, and three components;

[0031] 2. Mix the weighed thiosalicylic acid and phthalic acid evenly, then add water and stir until the thiosalicylic acid and phthalic acid are completely dissolved;

[0032] 3. Add the weighed tannin extract to the solution obtained in step 2 and stir until the material system is uniform and transparent to obtain the required copper-lead concentrate flotation separation inhibitor.

Embodiment 2

[0034] 1. In parts by weight, weigh 15 parts of phthalic acid, 10 parts of thiosalicylic acid, 3 parts of tannin extract, and three components;

[0035] 2. Mix the weighed thiosalicylic acid and phthalic acid evenly, then add water and stir until the thiosalicylic acid and phthalic acid are completely dissolved;

[0036] 3. Add the weighed tannin extract to the solution obtained in step 2 and stir until the material system is uniform and transparent to obtain the required copper-lead concentrate flotation separation inhibitor.

Embodiment 3

[0038] 1. In parts by weight, weigh 20 parts of phthalic acid, 12 parts of thiosalicylic acid and 4 parts of tannin extract;

[0039] 2. Mix the weighed thiosalicylic acid and phthalic acid evenly, then add water and stir until the thiosalicylic acid and phthalic acid are completely dissolved;

[0040] 3. Add the weighed tannin extract to the solution obtained in step 2 and stir until the material system is uniform and transparent to obtain the required copper-lead concentrate flotation separation inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com