wet wall tower

A wetted wall tower and wetted wall column technology, applied in the field of gas capture equipment, can solve the problems of uneven gas distribution, high axial velocity, etc., and achieve the effects of reducing impact, eliminating volatility, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

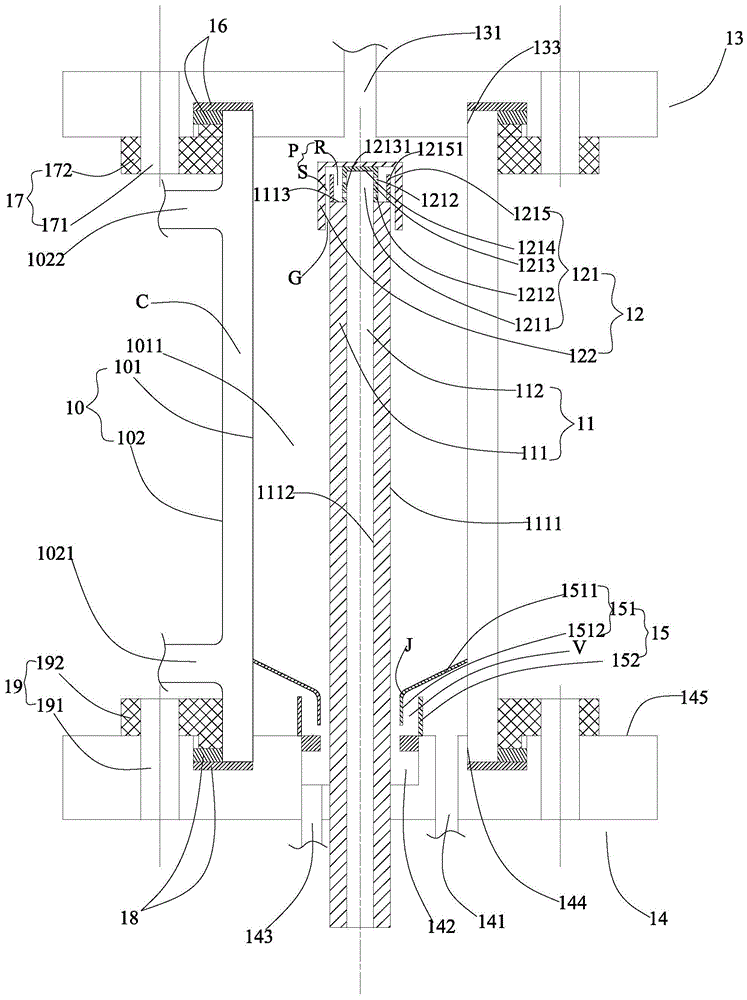

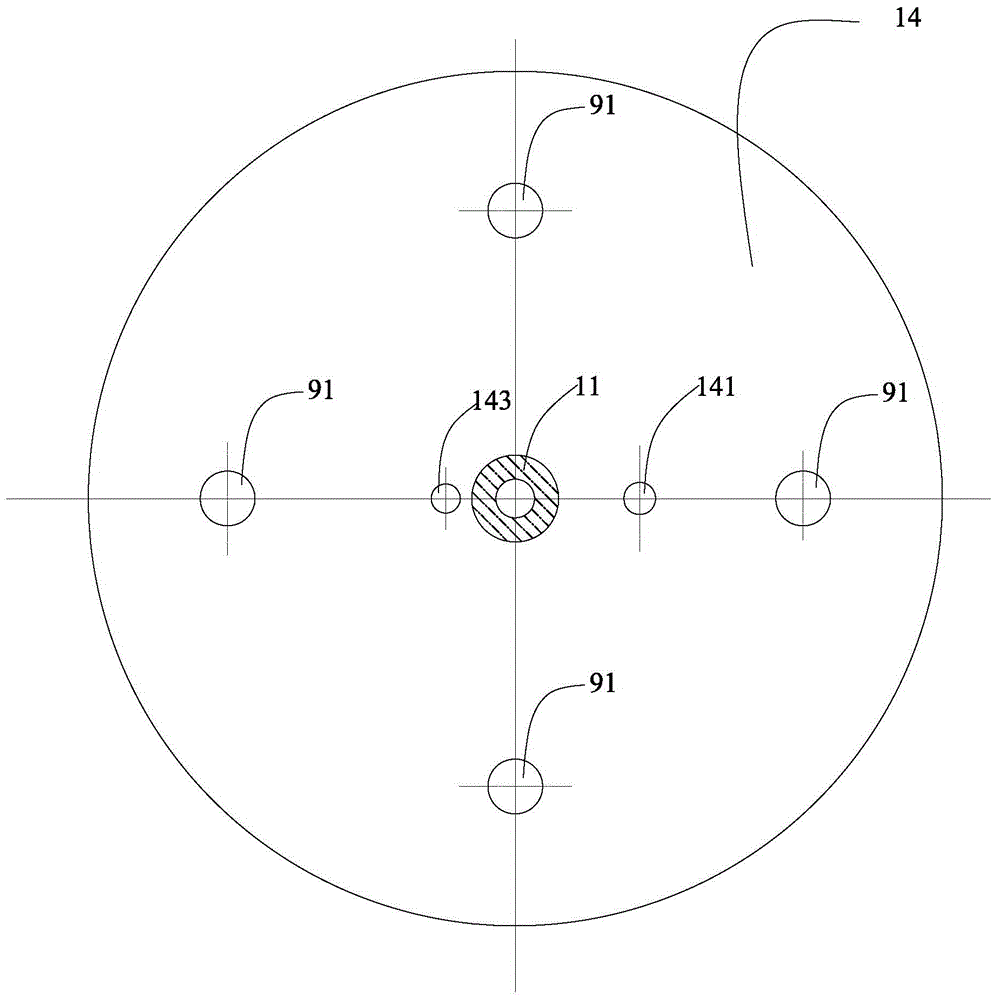

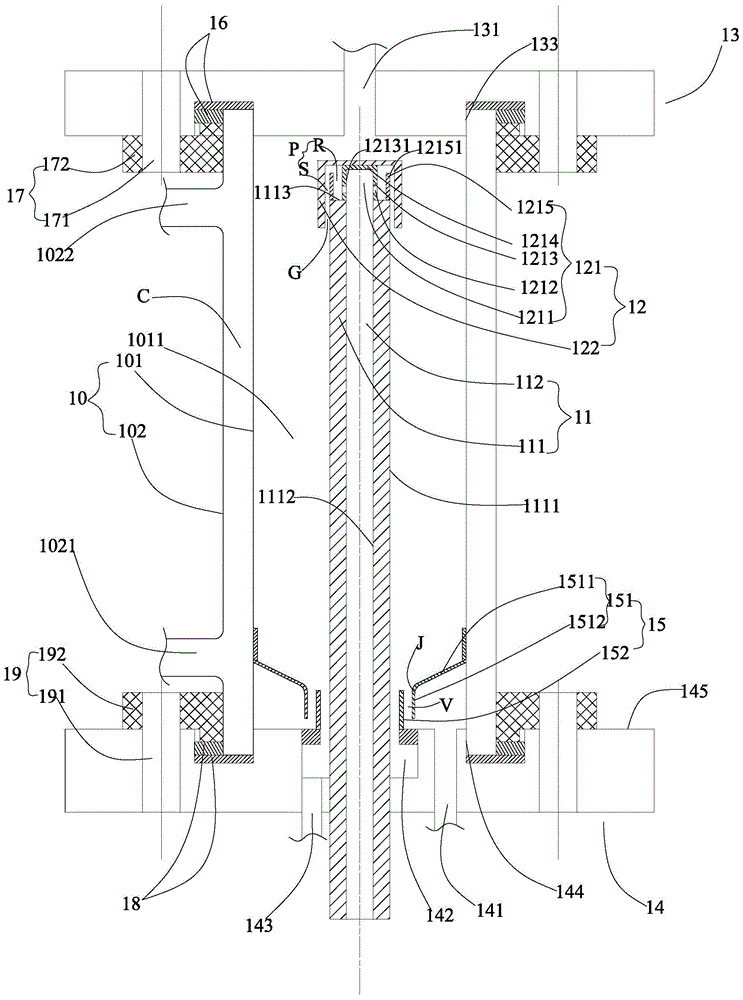

[0059] The wetted wall column according to the present invention will be described in detail below with reference to the accompanying drawings.

[0060] refer to Figure 1 to Figure 5 , The wetted wall column according to the present invention includes a jacket 10 , a wetted wall column 11 , a liquid distributor 12 , an upper flange 13 , a lower flange 14 and a gas distribution baffle 15 .

[0061] The jacket 10 has: an inner wall 101, which forms an accommodating cavity 1011; and an outer wall 102, which surrounds the inner wall 101 and forms a cavity C with the inner wall 101, and is provided with an insulating liquid inlet 1021 and an insulating liquid outlet 1022 communicating with the cavity C, The insulation fluid inlet 1021 , the cavity C and the insulation fluid outlet 1022 form a passage for the insulation fluid (not shown), and the insulation fluid flowing through the passage keeps the accommodating chamber 1011 insulated.

[0062] The wetted pilaster 11 is accommod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com