Chitosan petrolatum gauze and preparation method thereof

A technology of chitosan and vaseline, which is applied in medical science, bandages, absorbent pads, etc., can solve the problem of not having antibacterial properties, and achieve the effect of strengthening anti-infection ability, simple materials, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The making of embodiment 1 chitosan vaseline gauze

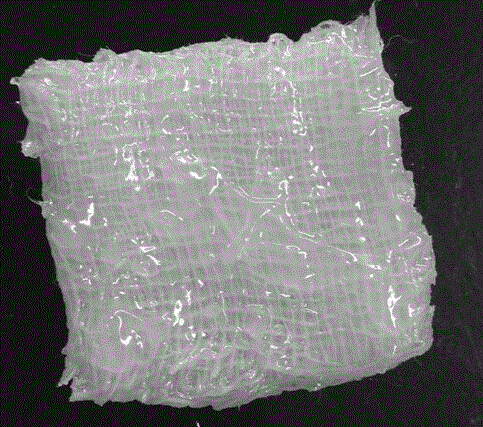

[0032] Add 1.5g of high molecular weight chitosan (molecular weight is 800,000) and 1.5g low molecular weight chitosan (molecular weight of 3,000) into 97g of weakly acidic solution, stir well to obtain 3% chitosan mixture; Immerse the degreased gauze in the chitosan mixture for 24 hours, take out the gauze, and dry it in a drying oven at 60-65°C for 1 hour; soak the dried gauze in melted vaseline paraffin oil (the weight ratio of vaseline to paraffin is 2:1) ) for 1 minute, take it out and drain; then sterilize with ethylene oxide to get 3% chitosan vaseline gauze ( figure 1 , is the superposition of multi-layer chitosan vaseline gauze). The weakly acidic solution here is 1% acetic acid.

Embodiment 2

[0033] Embodiment 2 The making of chitosan vaseline gauze

[0034] Add 0.5g of high molecular weight chitosan (molecular weight of 200,000 and half of 500,000) and low molecular weight chitosan (molecular weight of 50,000 and half of 100,000) to 99g of 1% acetic acid solution, stir well and prepare 1% chitosan mixture; immerse common degreasing gauze in the chitosan mixture for 12 hours, take out the gauze, and dry it in a lyophilizer for 6 hours; soak the dried gauze in vaseline paraffin oil (Vaseline and The weight ratio of paraffin wax is 1:2) for 1 hour, take out and drain, and obtain 1% chitosan vaseline gauze. Here, the chitosan mixture is sterilized by filtration, the vaseline paraffin oil mixture is sterilized by high pressure steam, and the weakly acidic solution is 0.5% sorbic acid.

Embodiment 3

[0035] Embodiment 3 The making of chitosan vaseline gauze

[0036] Add 2g of high molecular weight chitosan (1g each with molecular weights of 200,000 and 800,000) and 3g of low molecular weight chitosan (1g each with molecular weights of 3,000, 10,000 and 50,000) into 95g of weakly acidic solution, stir well Prepare a 5% chitosan mixture; immerse ordinary degreasing gauze in the chitosan mixture for 48 hours, take out the gauze, and dry it in a drying oven at 60~65°C for 3 hours; dip the dried gauze into the melted Vaseline paraffin oil (weight ratio of vaseline and paraffin is 1:1) for 30 minutes, take out and drain; then sterilize with ethylene oxide to obtain 5% chitosan vaseline gauze. The weakly acidic solution here is 2% citric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com