Vacuum coconut treatment process

A technology of vacuum treatment and coconut fruit, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of high cost, low calorie, and high energy consumption, and achieve the effects of short processing time, low energy consumption, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

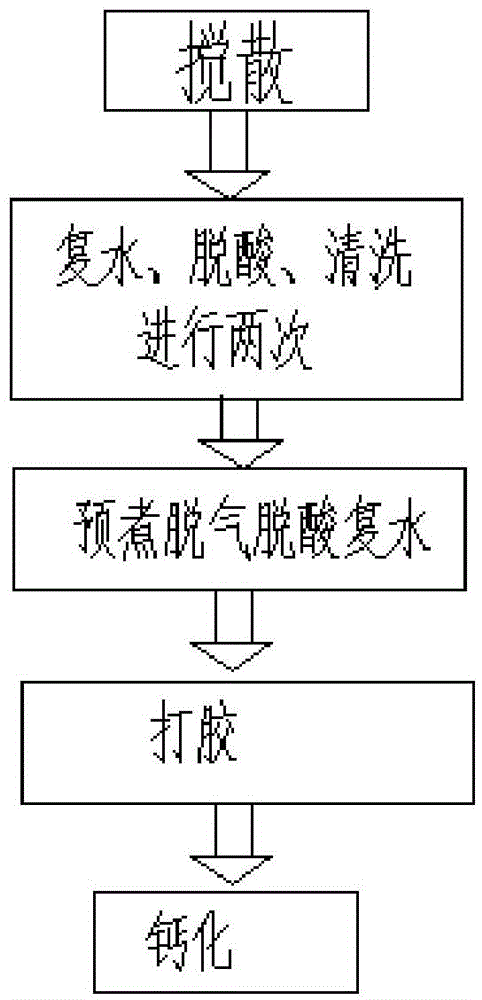

[0021] refer to figure 1 , a coconut fruit vacuum treatment process, its concrete steps are as follows:

[0022] 1. Stir up

[0023] Pour the coconuts into the pretreatment bucket, add enough water to stir up the coconuts, so that the water in the bucket will disperse the coconuts.

[0024] 2. Rehydration, deacidification, cleaning

[0025] One-time rehydration, deacidification and cleaning: suck the stirred coconuts into the treatment tank by vacuum through the pipeline, add a certain amount of clean water, and turn on the blower to blow air on the coconuts, so that the coconuts will move violently under the action of external force. After blowing air for 20 minutes, close the vent valve, open the vacuum valve, raise the vacuum degree in the treatment tank to 500mmHg, and maintain it for 5 minutes, so that the coconut fruit will infiltrate into the clear water and discharge the acid in the coconut fruit during the intense exercise. When the water rate reaches 30%-40%, clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com