Microwell plate

A technology of micro-orifice plate and open side, which is applied in the field of micro-orifice plate, can solve the problems such as difficult formation of cell agglutination, and achieve the effect of good formation, ensured well capacity and sufficient well capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

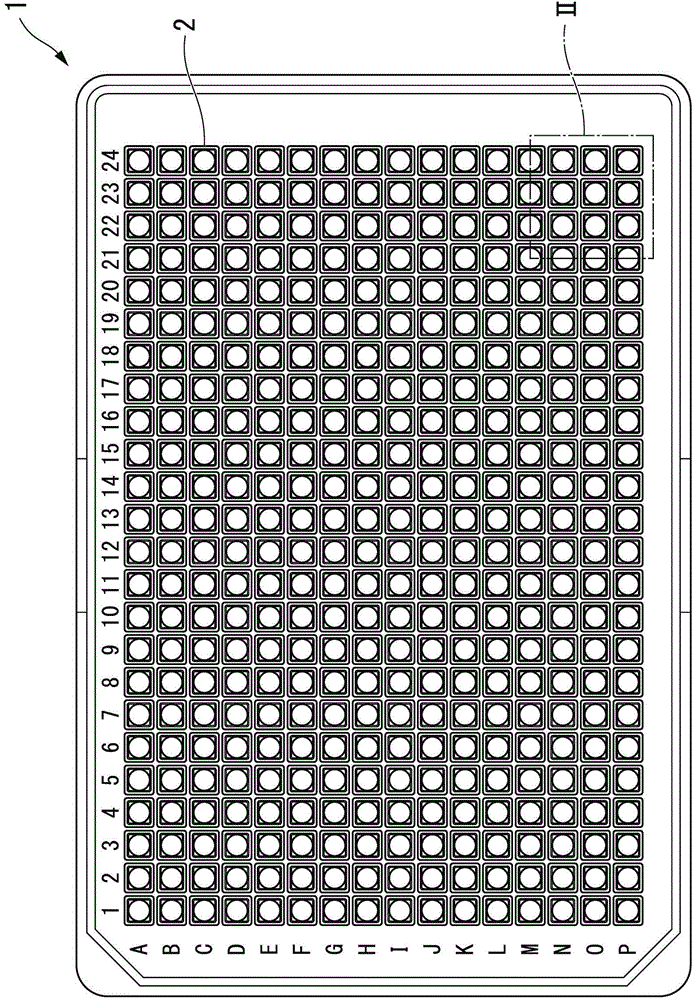

[0056] Injection molding using transparent polystyrene resin (manufactured by PS Japan Co., Ltd., HF77) and transparent polystyrene resin mixed with 15% white pigment titanium dioxide (manufactured by SUMIKA COLORCO.,LTD.) Form two types of 384-well microplates, transparent and white.

[0057] The shape of the obtained microplate was 127.7 mm in width, 85.5 mm in length, and 14.4 mm in height.

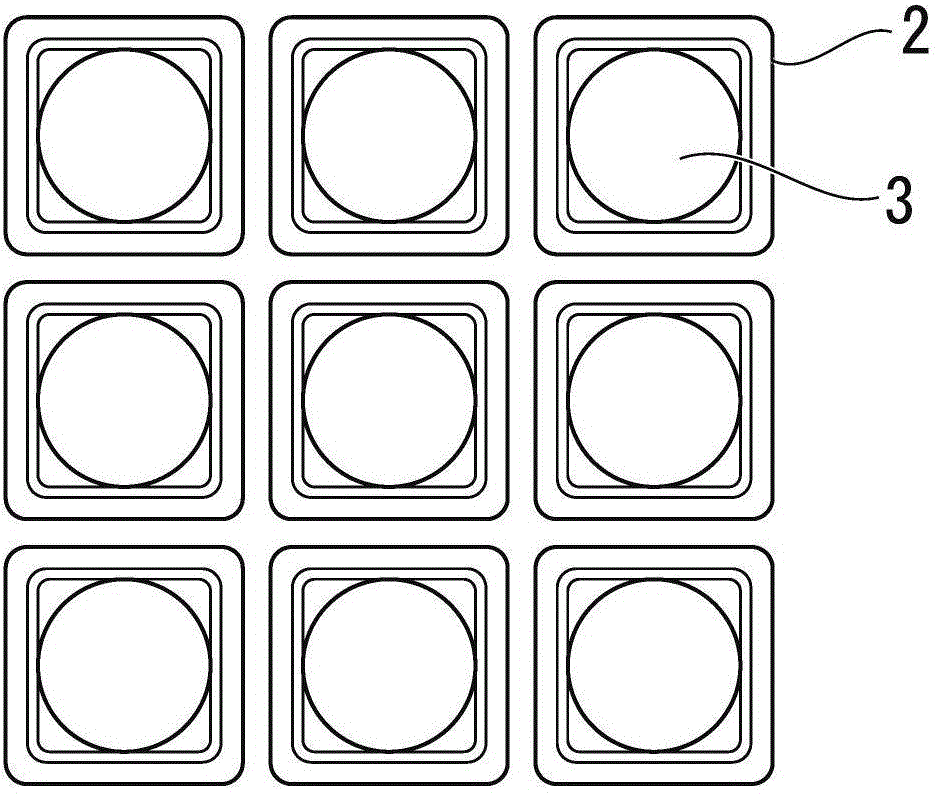

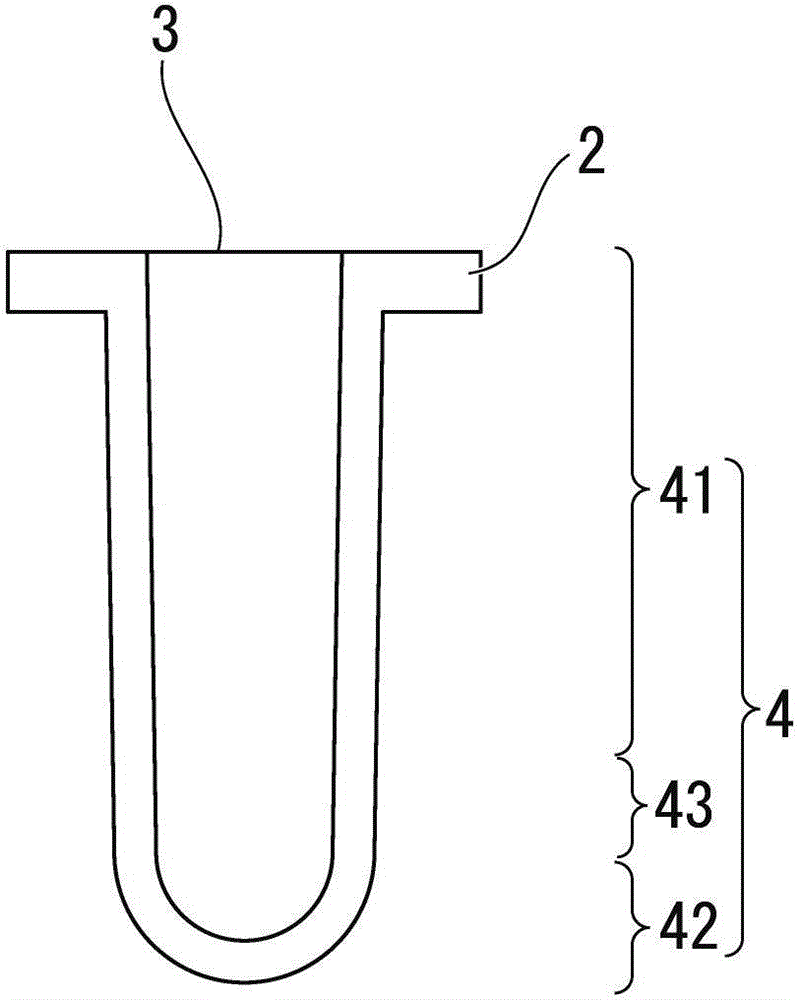

[0058] In addition, the shape of each hole is as image 3 As shown, the opening is a quadrilateral with a side of 3.3 mm, a depth of 12 mm, a radius of curvature of the bottom of 1.5 mm, and a pore volume of 108.4 μL.

[0059] In addition, the depth of the opening side portion 41 is 8.8 mm, the total depth of the bottom side portion 42 and the transition portion 43 is 3.2 mm, and the depth ratio is 15:4.

[0060] The obtained plate was subjected to plasma treatment (oxygen plasma for 10 minutes) using a plasma treatment apparatus (SERIES 7000 manufactured by Branson / IPC Co., Ltd.) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com