Improved plunger type fluid pump and motor

A plunger type, fluid pump technology, applied in the field of fluid pumps and motors, can solve the problems of power loss and temperature rise, increase mechanical wear, etc., and achieve the effect of eliminating fluid temperature rise, increasing mechanical wear, and eliminating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

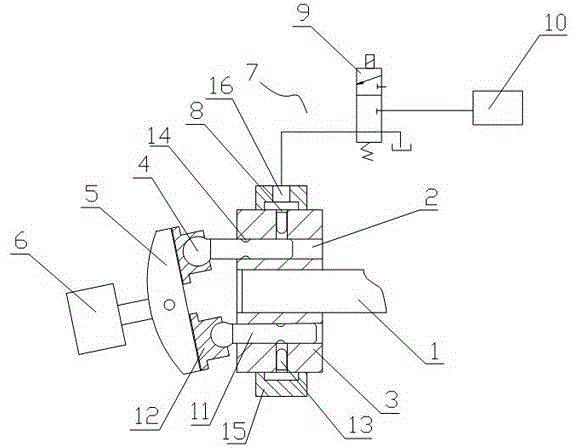

[0023] exist figure 1 In the shown embodiment, the improved plunger type fluid pump and motor include a cylinder body 3 with a fluid chamber 2 mounted on a shaft 1, a plurality of plunger assemblies 4 sliding in the cylinder body 3, and the plunger assembly The variable plate 5 in contact with 4 and the variable mechanism 6 connected with the variable plate 5, the plunger type fluid pump and the motor are also provided with a plunger holding device 7 to keep the plunger assembly 4 separated from the variable plate 5 or to restore contact. The plunger holding device 7 is a hydraulic control device. The plunger holding device 7 includes a control chamber 8, a control valve 9 and a control fluid 10. The control valve 9 is a two-position three-way valve. The control fluid 10 is connected with the control chamber 8 through the control valve 9, and the control fluid 10 comes from an external low-pressure fluid. The plunger assembly 4 is in the form of a plunger shoe part, including...

Embodiment 2

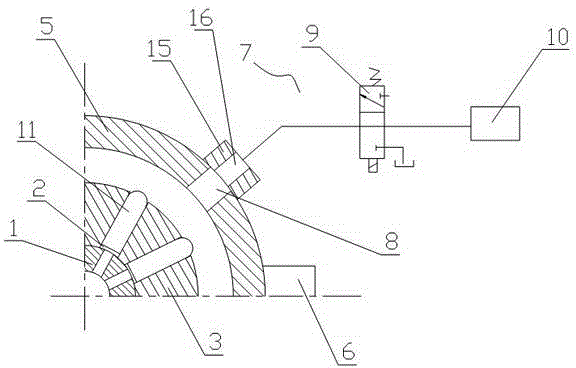

[0025] exist image 3In the shown embodiment, the improved plunger type fluid pump and motor include a cylinder body 3 with a fluid chamber 2 mounted on a shaft 1, a plurality of plunger assemblies 4 sliding in the cylinder body 3, and the plunger assembly The variable plate 5 in contact with 4 and the variable mechanism 6 connected with the variable plate 5, the plunger type fluid pump and the motor are also provided with a plunger holding device 7 to keep the plunger assembly 4 separated from the variable plate 5 or to restore contact. The plunger holding device 7 is a hydraulic control device. The plunger holding device 7 includes a control chamber 8, a control valve 9 and a control fluid 10. The control valve 9 is a two-position three-way valve. The control fluid 10 is connected with the control chamber 8 through the control valve 9, and the control fluid 10 comes from an external low-pressure fluid. The plunger assembly 4 is a plunger structure, including a plunger 11 , ...

Embodiment 3

[0027] exist Figure 4 In the shown embodiment, the improved plunger type fluid pump and motor include a cylinder body 3 with a fluid chamber 2 mounted on a shaft 1, a plurality of plunger assemblies 4 sliding in the cylinder body 3, and the plunger assembly The variable plate 5 in contact with 4 and the variable mechanism 6 connected with the variable plate 5, the plunger type fluid pump and the motor are also provided with a plunger holding device 7 to keep the plunger assembly 4 separated from the variable plate 5 or to restore contact. The plunger holding device 7 is a hydraulic control device. The plunger holding device 7 includes a control chamber 8, a control valve 9 and a control fluid 10. The control valve 9 is a two-position three-way valve. The control fluid 10 is connected with the control chamber 8 through the control valve 9, and the control fluid 10 comes from an external low-pressure fluid. The plunger assembly 4 is a plunger structure, including a plunger 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com