Energy dissipation shear wall with built-in trusses and construction method of shear wall

A construction method and shear wall technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems that the prefabricated block shear wall cannot meet the requirements of high-rise buildings against lateral stiffness, and the effect of ductility and bearing capacity is weak. , to achieve the effect of facilitating the promotion of the industrialized model, good energy consumption and anti-seismic effect, and standardized production size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

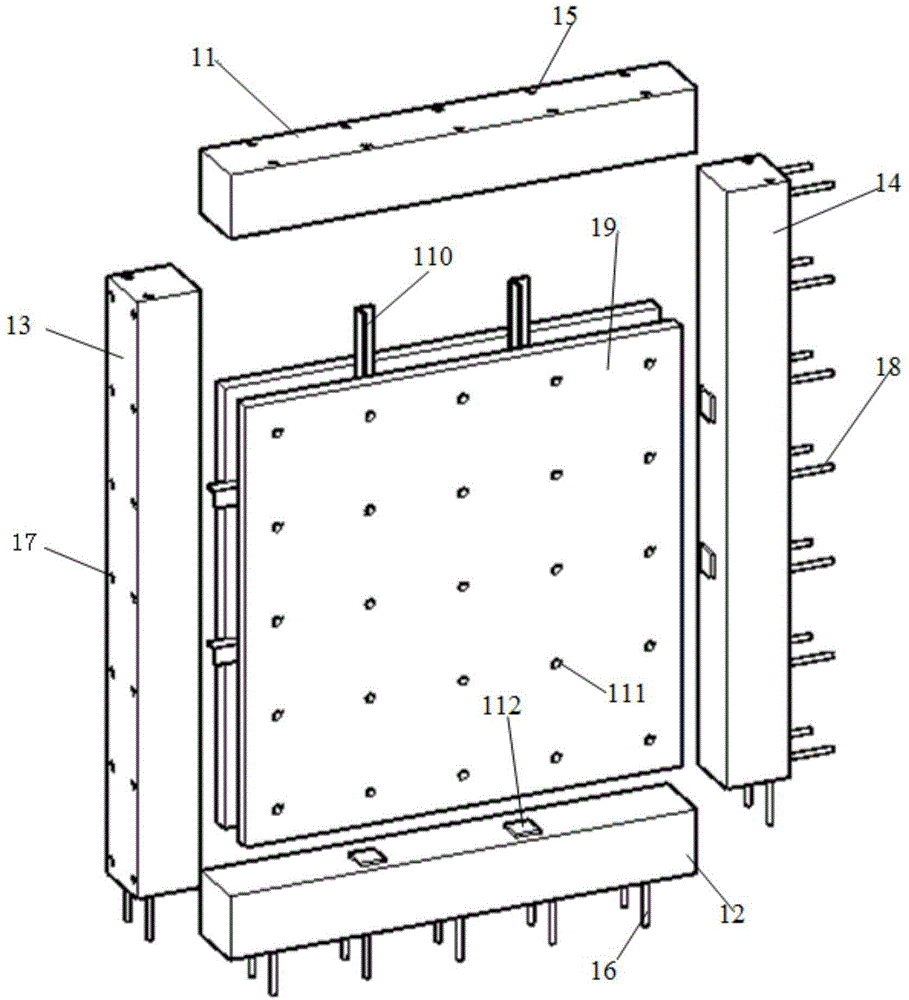

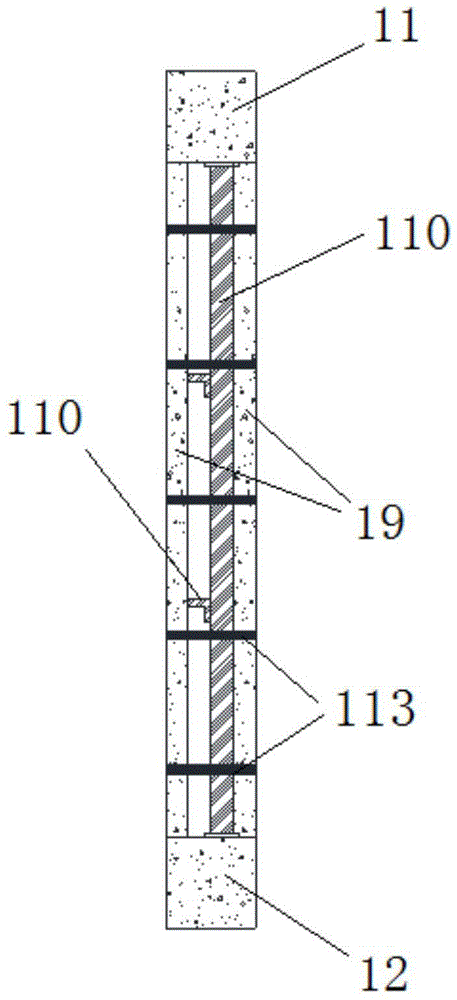

[0043] Such as Figure 1-Figure 5 As shown, the energy-dissipating shear wall with built-in trusses is mainly composed of built-in trusses, reinforced concrete slabs (i.e., shear wall panels 19) arranged on both sides of the trusses and restraining the out-of-plane deformation of the trusses, and edge frames connected with the built-in trusses ; The end of the truss is welded with the pre-embedded steel plate 112 of the edge frame; the edge frame is composed of the left edge frame column 13, the upper edge frame beam 11, the right edge frame column 14 and the lower edge frame beam 12; by changing the layout of the truss, it can Design different stiffness and strength of the shear wall, and then realize different yield loads and corresponding yield displacements, and achieve a design with controllable parameters. The shear wall panels 19 are provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com