Embedded type large-stroke lead damper

A large-stroke, nested technology, applied to building components, shockproof, etc., can solve the problems of large fluctuations in damper output and small damping output, so as to avoid uneven output, increase stroke, and increase shear area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

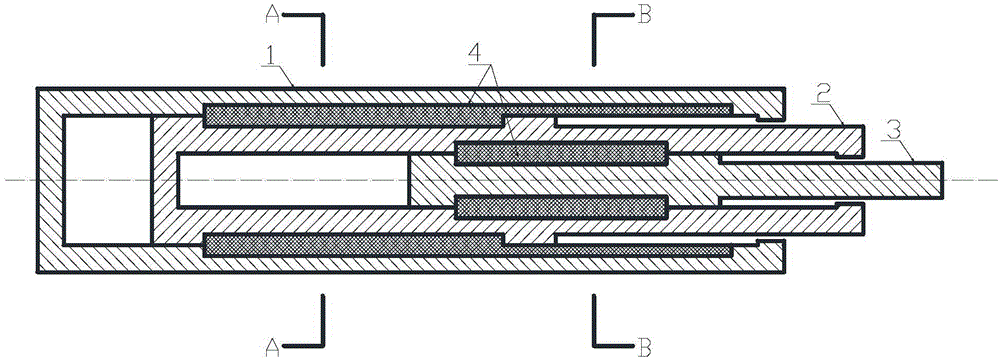

[0016] Combine below Attached picture The present invention will be further described with specific embodiments.

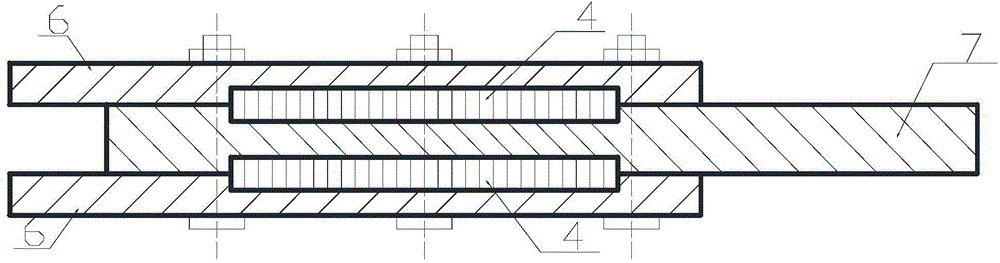

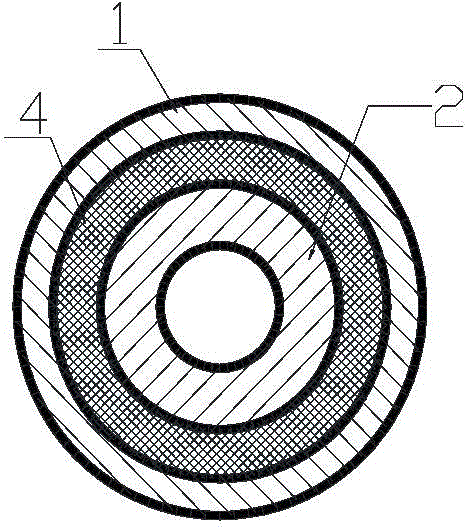

[0017] as shown in the picture and Figure Institute A nested large-stroke lead damper is shown, including an outer sleeve 1, an inner sleeve 2, a center rod 3, and a lead block 4; it is characterized in that: the outer sleeve 1 is set on the outer surface of the inner sleeve 2 , the inner sleeve 2 is set on the outer surface of the center tie rod 3; grooves are arranged on the two contact surfaces of the center tie rod 3 and the inner sleeve 2, and the grooves on the upper and lower surfaces are opposite to form an annular cavity; 1 and the inner sleeve 2 are provided with grooves on both contact surfaces, the groove of the outer sleeve 1 is longer than the groove of the inner sleeve 2 along the shear direction, and the grooves on the upper and lower surfaces are opposite to each other, forming a variable cross-section An annular cavity; a lead block 4 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com