Pretreatment method of lignocellulose raw material

A lignocellulose and pretreatment technology, which is applied in the processing of fiber raw materials, pulping of cellulose raw materials, and fiber raw materials, can solve the problems of high cost, cumbersome operation, inability to use slag fermentation and simultaneous saccharification fermentation, etc. Less loss, lower inhibitor content, and reduced inhibitor production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

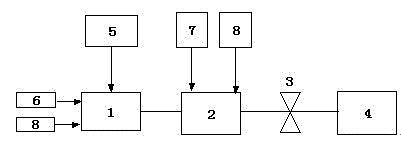

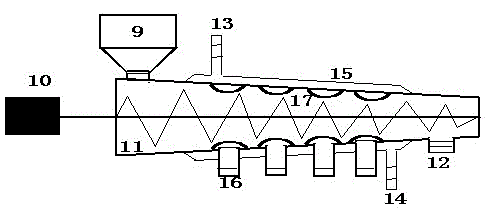

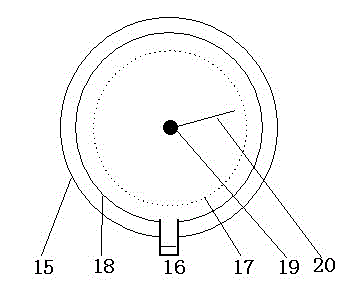

[0043] Using the invention figure 1 The process flow shown is to pretreat the lignocellulosic raw material. The immersion liquid used is tap water and heated to 90°C. Start the conical screw device and the equal-diameter screw device, and continuously add the heated soaking liquid and corn stalk particles into the conical screw at the ratio of liquid-solid mass ratio of 3:1 through the feeding hopper. The temperature in the conical screw is controlled. At 170℃, the residence time of corn stalks in the conical screw is 20 min by adjusting the frequency of the screw motor. The concentration of glucose in the extrudate of the conical screw device is 1 g / L, the concentration of xylose is 8 g / L, the total phenol is 75 mg / L, acetic acid is 7 g / L, furfural is 0.25 g / L, and others Check out. The raw materials after the first cooking enter the equal-diameter screw device, and tap water is added in the ratio of liquid-solid mass ratio of 1:3 for the second cooking. The temperature is ...

Embodiment 2

[0048] Using the same process conditions as in Example 1, the lignocellulosic raw material was pretreated. The difference is that the impregnation solution used contains 0.5wt% NaCl, 0.01wt% SDS and 0.6wt% ammonium oxalate, and is heated to 70°C.

[0049] The concentration of glucose in the extrudate of the conical screw device is 1 g / L, the concentration of xylose is 7 g / L, the total phenol is 80 mg / L, acetic acid is 7.5 g / L, furfural is 0.3 g / L, and others Check out.

[0050] The dry matter concentration of pretreated corn stalks (PCS) was 32.6wt%, the cellulose content of the dry matter was 40.3wt%, the semi-fiber content was 7.5wt%, the xylo-oligosaccharide content was 6.3wt%, and the xylose content was 9.7wt%. The concentration of xylose in the PCS extruded solution is 39.3g / L, the concentration of glucose is 5.2g / L, the concentration of xylo-oligosaccharide is 23.0g / L, the concentration of gluco-oligosaccharide is 1.1g / L, and the concentration of acetic acid is 2.8 g / L. The...

Embodiment 3

[0054] The same process conditions as in Example 1 are adopted, with the first difference being: the impregnation solution used contains 1.0 wt% NaCl, 0.05 wt% SDS, and 0.2 wt% ammonium oxalate, and is heated to 90°C. The second difference is that the liquid-solid mass ratio of the dipping liquid to the corn stover is 4:1, the residence time in the conical screw is 25 min, and the cooking temperature is controlled at 150°C. The third difference is: the liquid-solid mass ratio in the equal-diameter screw device is 1:2, the temperature is controlled at 220 ℃, and the residence time is 10 min.

[0055] The concentration of glucose in the conical screw extruded liquid is 0.8 g / L, the concentration of xylose is 6 g / L, the total phenol is 78 mg / L, the acetic acid is 7.4 g / L, and the furfural is 0.2 g / L. Others are not detected .

[0056] The dry matter concentration of the pretreated corn stover (PCS) was 34.8wt%, the cellulose content of the dry matter was 39.8wt%, the semi-fiber conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com