Front-loading washer and inner tub thereof

The technology of a drum washing machine and an inner drum is applied in other washing machines, washing devices, textiles and paper making, etc., which can solve the problems of high power consumption and achieve the effect of reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] It should be noted that in this embodiment, the opening side of the washing machine inner drum is called the front, and the side opposite to the opening end of the washing machine inner drum is called the rear, and the front and rear sides, front and rear of each component are defined according to this standard. end.

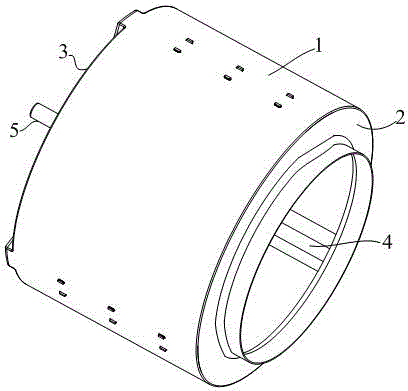

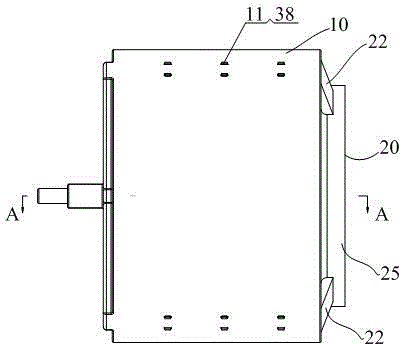

[0019] refer to Figure 2 to Figure 7 , the inner cylinder of the drum washing machine in this embodiment includes a cylinder body 10 and a front flange 20, and the front flange 20 is fixedly connected to the front end of the cylinder body 10 by means of screws or flanging pressing, and has a central opening 24, so that The inner space of the body 10 is used to pick and place clothes; at the same time, the inner surface of the cylinder wall of the cylinder body 10 is equipped with a raised elongate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com