Morphology improvement method of LLM-105 explosives on basis of crystal-form modifying agent

A technology for modifiers and explosives, applied in the field of improving the morphology of LLM-105 explosives based on crystal modifiers, can solve problems such as poor solubility, achieve mild reaction conditions, improve crystal morphology, and have good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

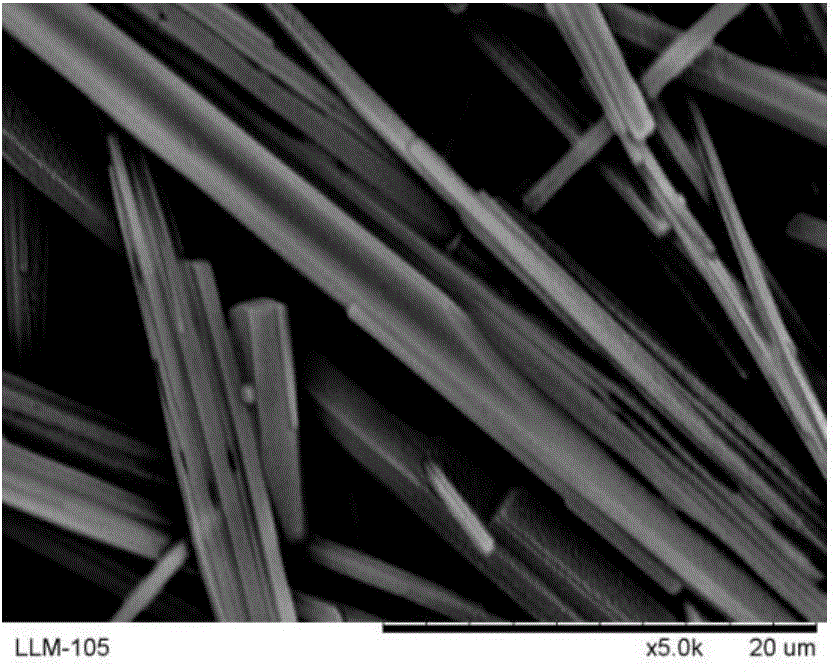

[0034] At room temperature, add 100g of dimethyl sulfoxide into the crystallizer, then add 6g of raw material LLM-105 explosive under stirring, raise the temperature to 80°C to obtain a saturated solution of LLM-105 explosive; then add 0.06g Add urea in the saturated solution of LLM-105 explosive, stir evenly, then adopt the dissolution crystallization method, drop ethyl acetate 300g with the speed of 2ml / min at this temperature, filter, wash, dry to obtain such as figure 1 The needle-like LLM-105 crystal shown is 5.16 g, and the yield is 86%.

Embodiment 2

[0036] At room temperature, add 300g of dimethylformamide into the crystallizer, then add 6g of raw material LLM-105 explosive under stirring, raise the temperature to 65°C to obtain a saturated solution of LLM-105 explosive; then add 0.1g Cyclohexanone was added to the saturated solution of LLM-105 explosives, stirred evenly, and then using the dissolution crystallization method, 600g of absolute ethanol was added dropwise at a speed of 2ml / min at this temperature, filtered, washed, and dried to obtain needle-shaped LLM- 4.62 g of 105 crystals, yield 77%.

Embodiment 3

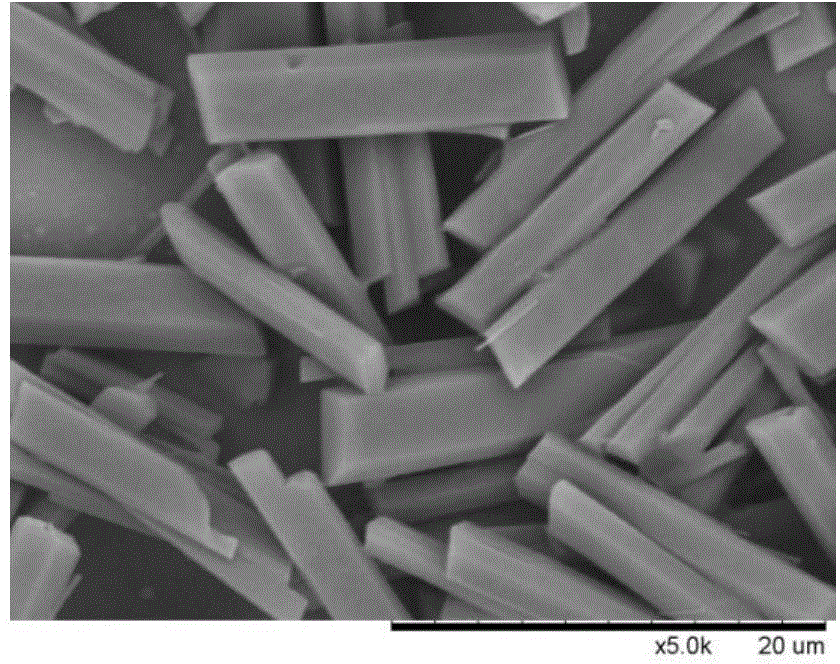

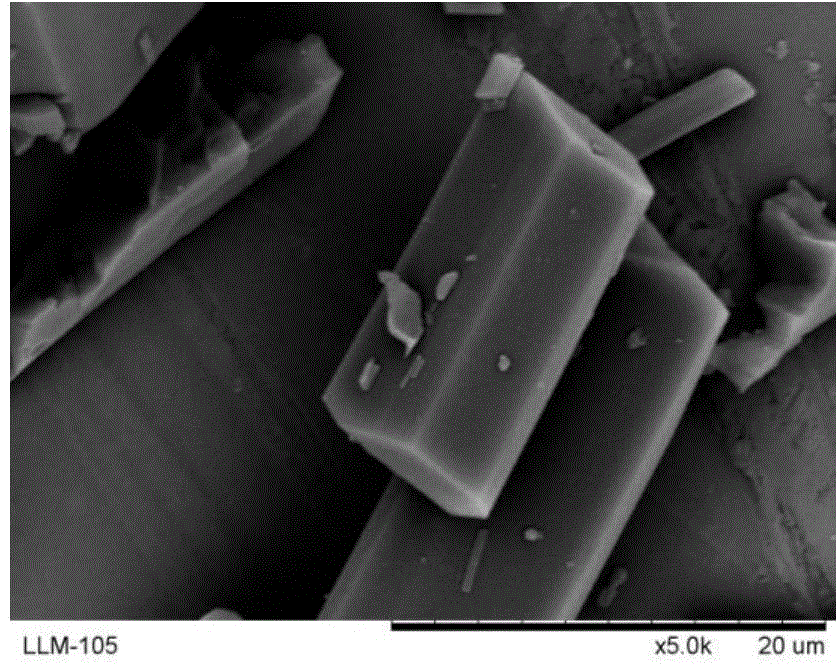

[0038] At room temperature, add 100g of dimethyl sulfoxide into the crystallizer, then add 6g of raw material LLM-105 explosive under stirring, raise the temperature to 90°C to obtain a saturated solution of LLM-105 explosive; then add 0.06g Glycine is added in the saturated solution of LLM-105 explosive, stirs evenly, adopts elution crystallization method then, drops anhydrous methanol 300g with the speed of 1ml / min at this temperature, filters, washes, dries to obtain such as figure 2 The shown rod-shaped LLM-105 crystals were 5.34 g, and the yield was 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com