Domestic lift

A technology for home elevators and elevator guide rails, which is applied to elevators, lifts, transportation and packaging in buildings, etc. It can solve the problems of reducing the service life of elevators, inability to disassemble, and small elevator shaft dimensions, so as to reduce the difficulty of shaft construction. The effect of prolonging the service life and saving the hoistway space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

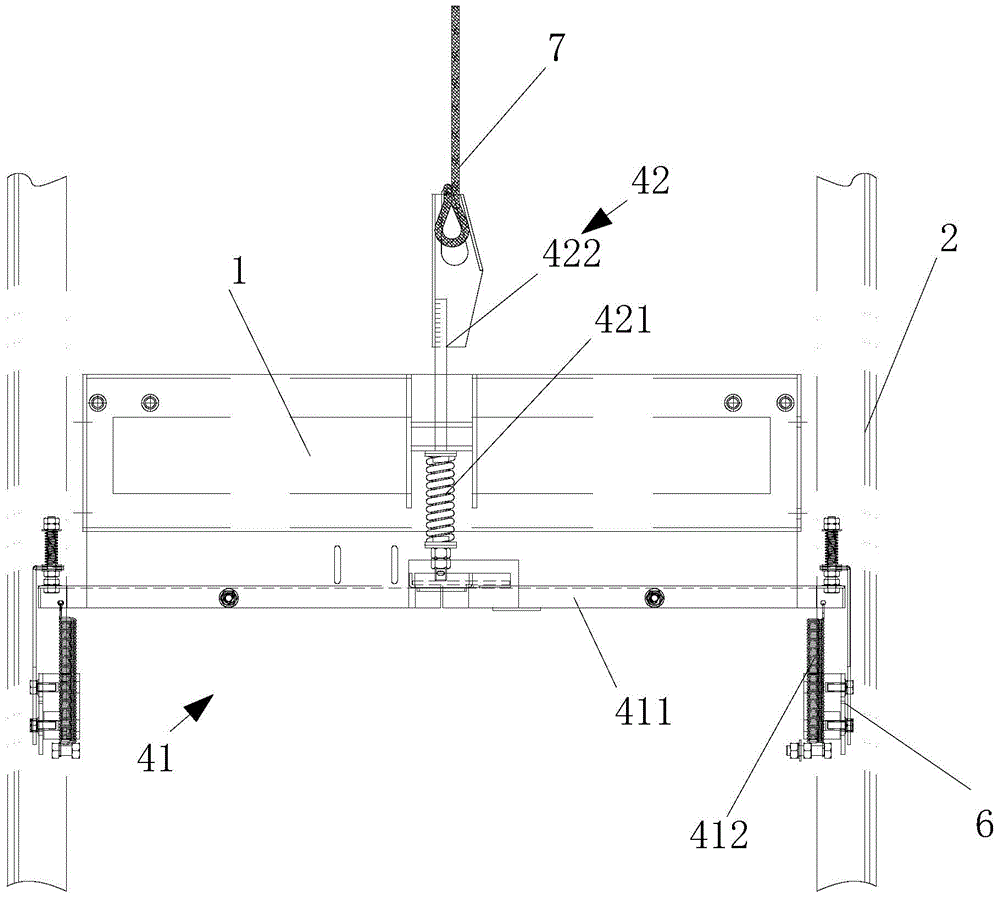

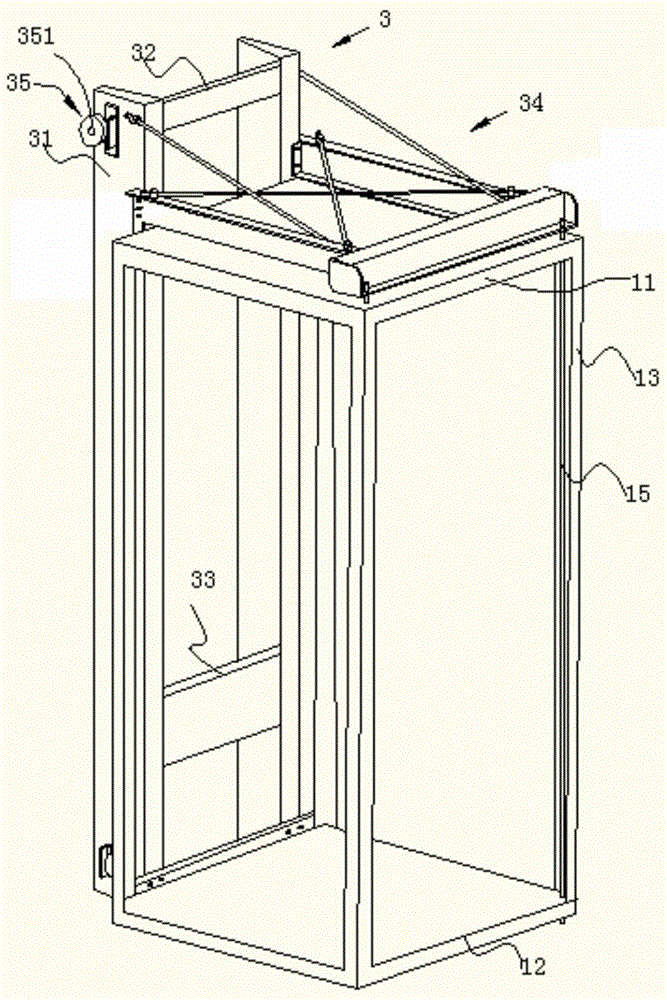

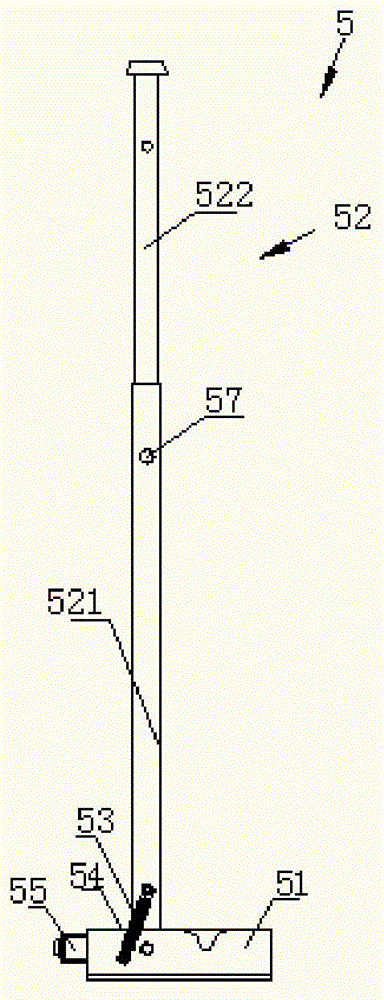

[0025] A home elevator, which includes a car 1, a backpack frame 3 that is slidably connected to the elevator guide rail 2 and used to fix the car 1, a safety gear trigger device 4 installed on the backpack frame 3, and installed on the car 1. The upper end or the safety protection device 5 installed at the pit bottom of the elevator shaft;

[0026]The car 1 includes a cuboid car top 11, a cuboid car bottom 12, a column 13 connecting the car top 11 and the car bottom 12, and a car wall 14 installed between the columns 13. The backpack rack 3 It includes two straight beams 31 arranged in parallel, an upper beam 32 perpendicular to the straight beams 31 and connected between the upper ends of the two straight beams 31, and a lower beam 33 connected between the lower parts of the two straight beams 31, for The car 1 is suspended on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com