Automatic Feeding Device for Clutch Brake Wheel of Washing Machine

A technology for automatic feeding and braking of wheels, applied in washing devices, other washing machines, loading/unloading, etc., can solve the problems of high labor intensity and large workload of feeding workers, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

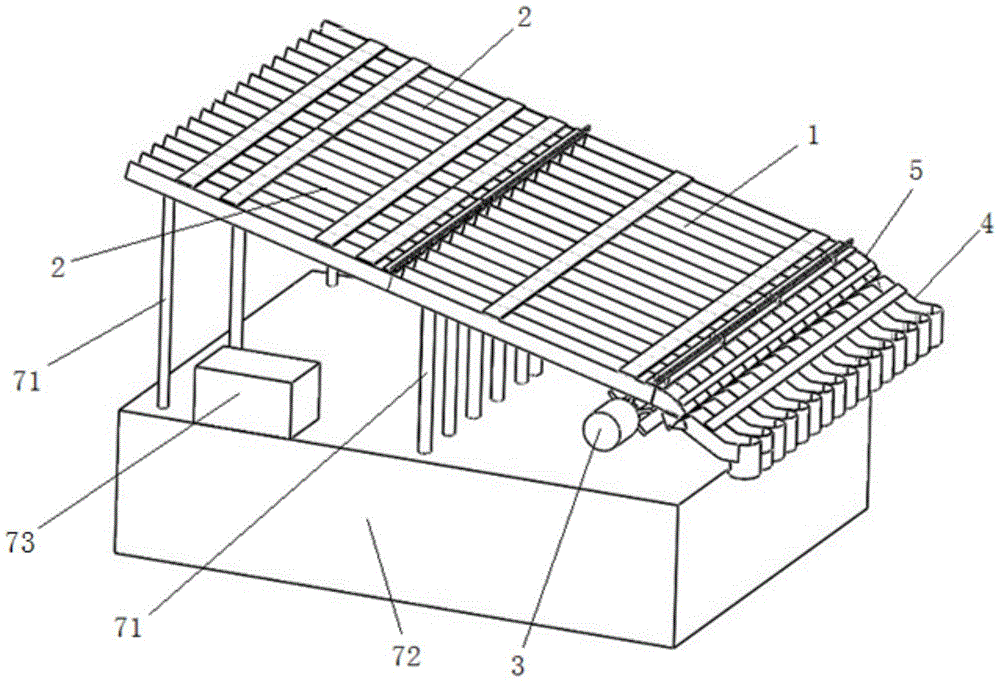

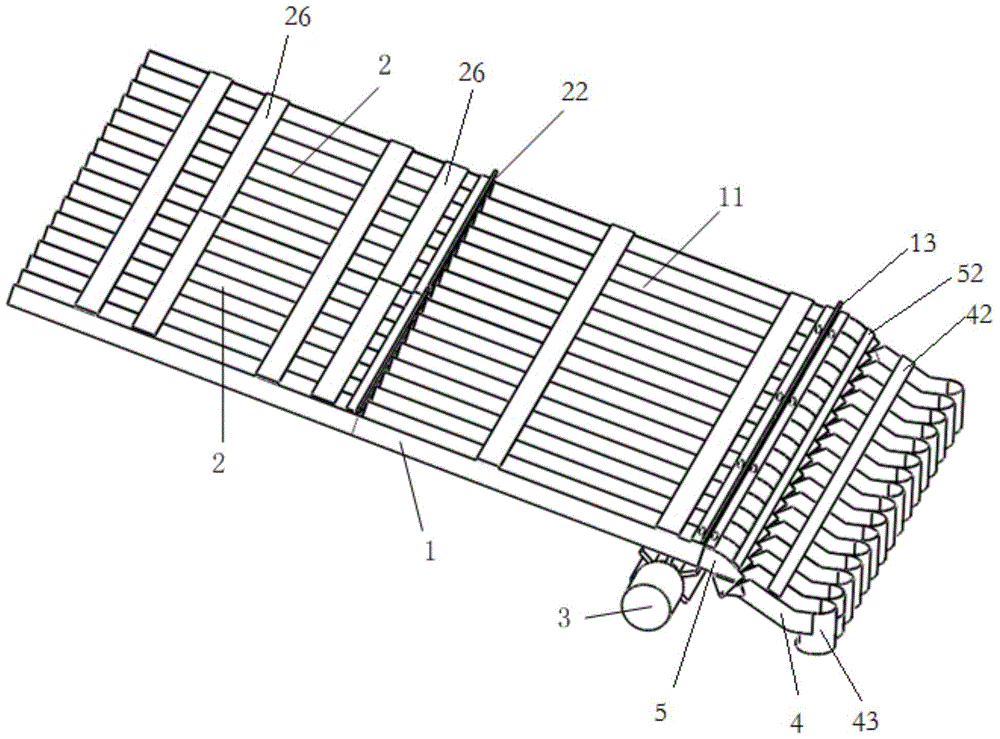

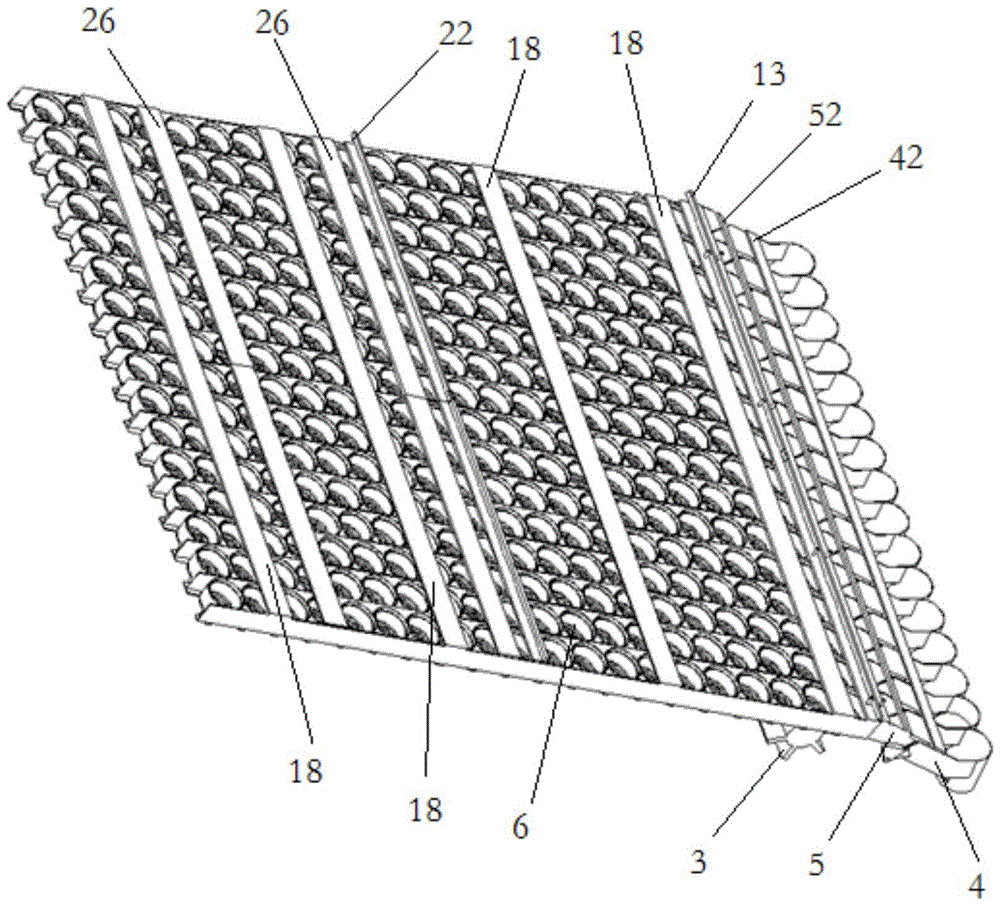

[0036] refer to Figure 1-10 : The automatic feeding device for the clutch brake wheel of the washing machine, including an inclined silo 1, the front of the inclined silo 1 is inclined downward, and the front part of the inclined silo 1 is arranged side by side with a plurality of first slides for the single row of brake wheels to slide. Rail 11, the first slide rail 11 is horizontally arranged, and the rear portion of inclined feed bin 1 is provided with support rail 12, and support rail 12 is inserted in the rear portion of inclined feed bin 1 side by side for a plurality of movable feed bins 2, and movable feed bin 2 It can be extracted and set on the support rail 12, and each movable bin 2 has a plurality of second slide rails 21 for single-row brake wheels to slide, and the exit of the second slide rail 21 corresponds to the entrance of the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com