A combined leaf moistening feeder

A feeding machine and combined technology, which is applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of unguaranteed absorption of material liquid and overflow of atomized material liquid, so as to reduce material liquid overflow, increase accuracy, and facilitate adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

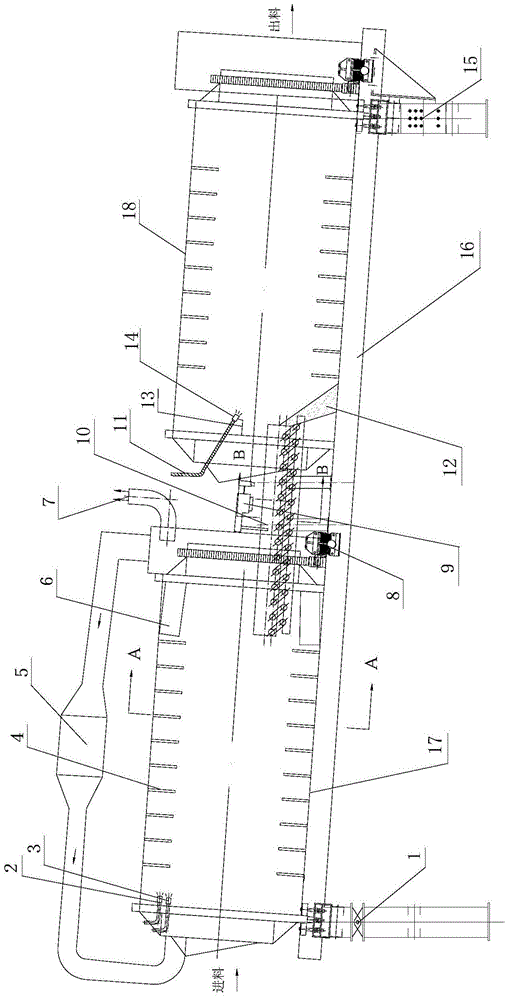

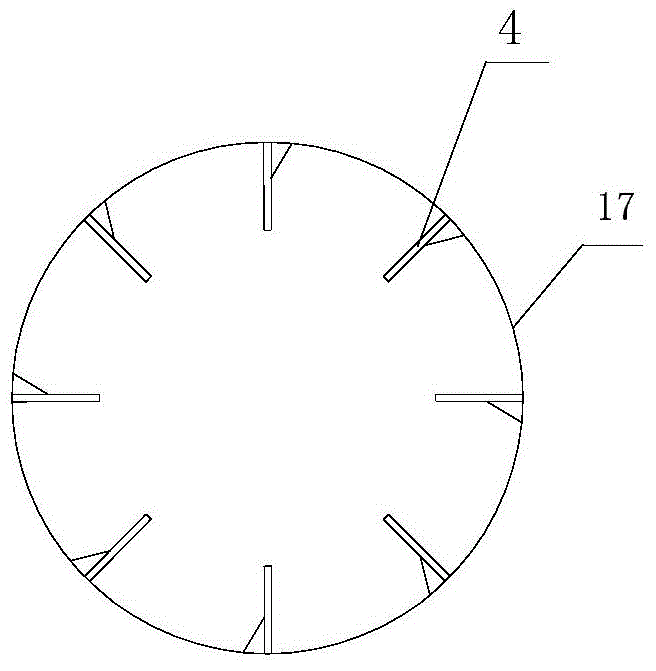

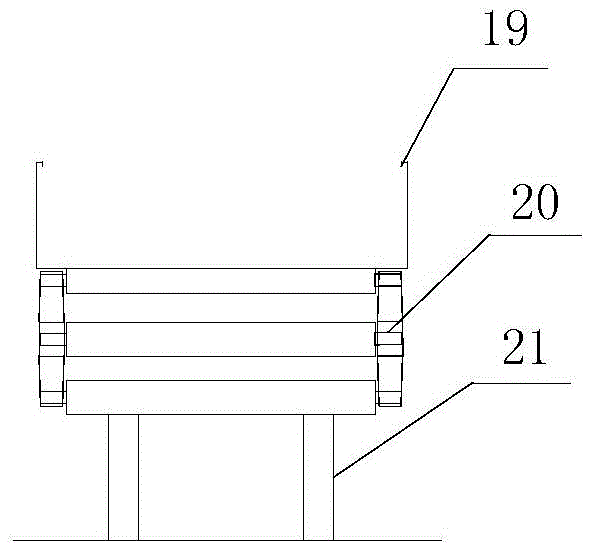

[0020] Such as figure 1 As shown, the combined leaf moistening feeder of the present invention includes a frame, a drum, a drive motor and a control system, which separates the two major links of the feeding process to form two drums, which are arranged on the frame 16 according to the front and rear positions, wherein The front cylinder is the leaf moistening cylinder 17, and the rear cylinder is the feeding cylinder 18. The leaf moistening cylinder 17 plays the function of the leaf moistening section in the work, and its difference with the traditional feeder is that the feeding link is stripped off, and the water adding nozzle 2 (water adding system), the steam adding nozzle 3 (humidifying system), the hot air System 5 and moisture removal system 7 are four systems. Under the action of these four systems, tobacco leaves are processed into tobacco leaves that meet the feeding requirements and process standards. The specific moisture and temperature control is detected by moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com