System for improving stability of stainless steel wire drawing

A stable, stainless steel technology, applied in the system field, can solve the problems affecting the drawing quality, loss, uneven surface of the drawing panel, etc., to achieve stable and effective contact and avoid movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

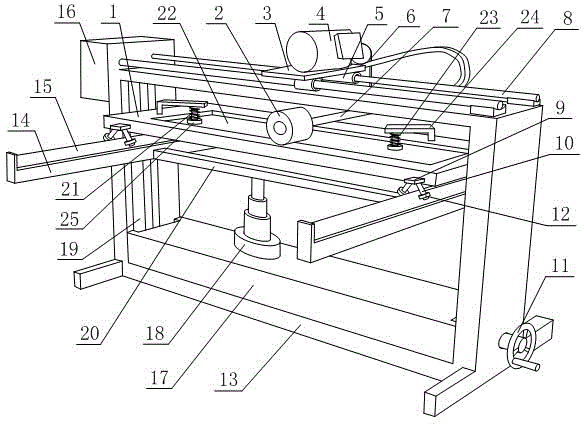

[0012] Such as figure 1As shown, the system for improving the stability of stainless steel wire drawing includes an internal hollow support frame 13, a support platform 1 is provided in the cavity of the support frame 13, and a limit frame is provided below the support platform 1, and the support platform 1 can be along the The limit frame slides horizontally, and the top surface of the support platform 1 is recessed to form a mounting groove 22. The center of the mounting groove 22 is arranged on the center line of the support platform 1. Several support arms 24 are provided on the top surface of the support platform 1 to support The bottom of arm 24 is all fixed with the top surface of support platform 1, and support arm 24 is L-shaped structure, and support arm 24 is all provided with compression spring 23, and the top of compression spring 23 is fixed with the inboard of support arm 24, presses The compression springs 23 are all arranged directly above the installation gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com