Magnetic nanomaterial supported ruthenium catalyst and application of magnetic nanomaterial supported ruthenium catalyst in preparation of 2, 5-dimethylfuran by catalyzing 5-hydroxymethylfurfural

A technology of hydroxymethylfurfural and magnetic nanometers, which is applied in the preparation and application of new catalyst materials, can solve the problems of unfavorable large-scale production and inconvenient catalyst recovery, and achieve simple recovery and reuse, not easy to deactivate, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

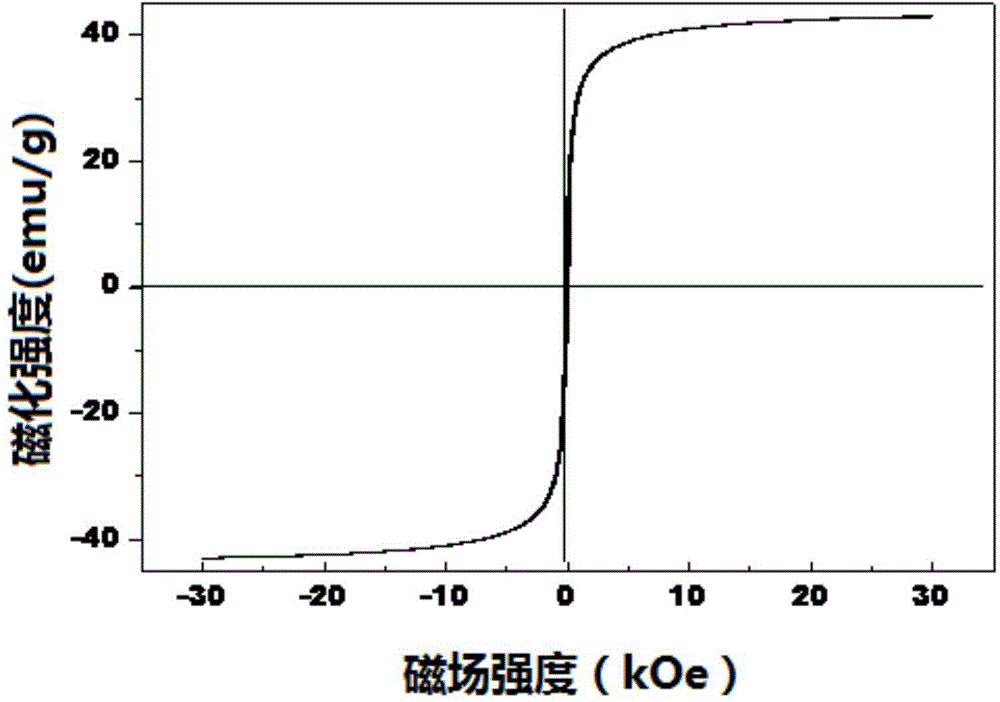

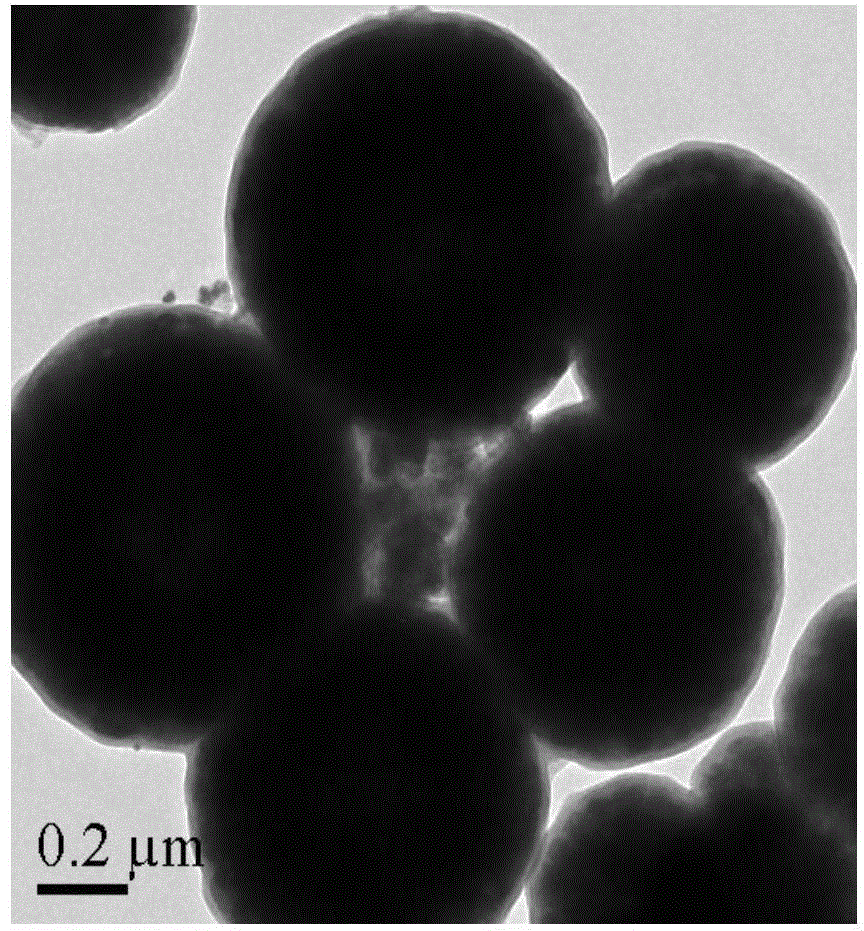

[0036] A magnetic nanomaterial loaded with ruthenium (Fe 3 o 4 C-Ru) the preparation method of catalyst, its step is as follows:

[0037] 1. Fe 3 o 4 Preparation of nanomaterials: synthesized according to the method designed by Diao Guowang et al. (J Phys Chem C 2011; 115:18923-34.). 1.5g FeCl 3 ·6H 2 O. 1g of polyvinylpyrrolidone (average molecular weight 1300000) and 2g of sodium acetate were added to 30mL of ethylene glycol, stirred vigorously for 2h, then the resulting mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and reacted at 200°C 8h, the resulting black precipitate was collected with a magnet, washed twice with ethanol, and then vacuum-dried at 60°C for 24h to obtain a black solid, namely Fe 3 o 4 nanomaterials.

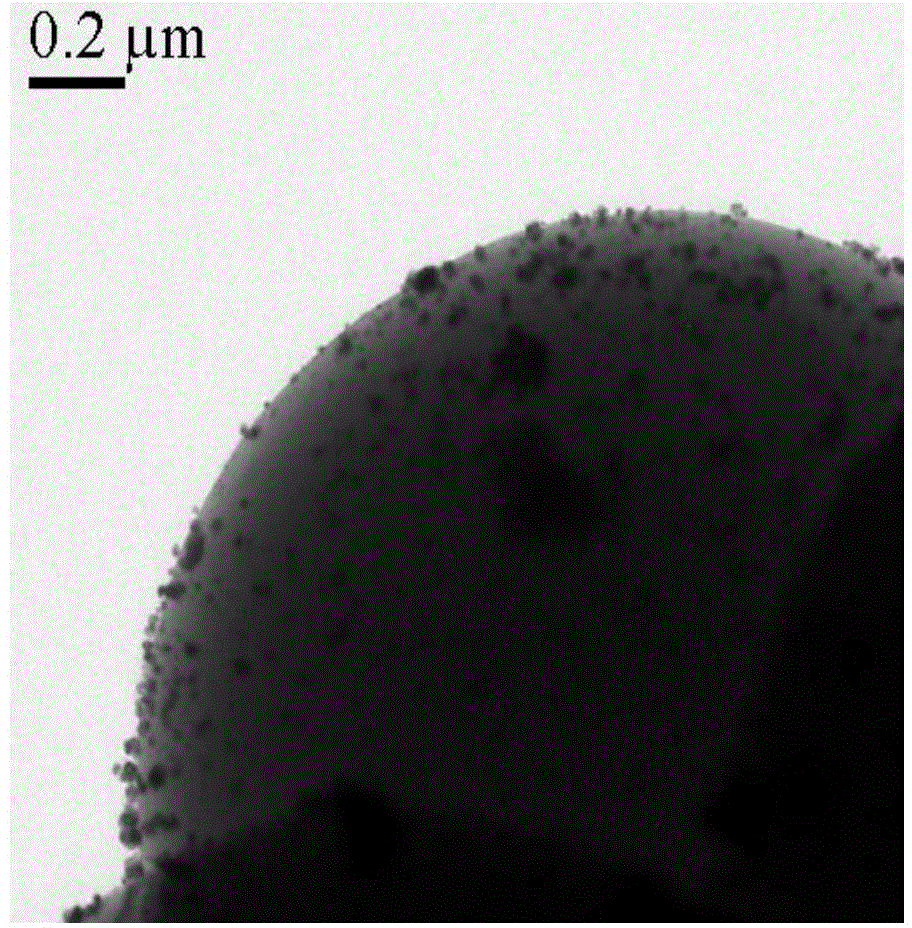

[0038] 2. Fe 3 o 4 C Preparation of magnetic nanomaterials: synthesized according to the method designed by Li Shenghai et al. (Langmuir 2010; 26:6676-80.). Fe obtained in step 1 3 o 4 Nanomaterials immers...

Embodiment 2

[0041] Utilize the Fe prepared by embodiment 1 3 o 4 C-Ru Catalyst Hydrogenation Reduction of 5-Hydroxymethylfurfural to Prepare 2,5-Dimethylfuran:

[0042] With HMF (50.4mg), tetrahydrofuran (THF, 12mL) and the Fe prepared in Example 1 3 o 4 The C-Ru catalyst (65mg) was added into a 50mL stainless steel reaction kettle, and the air was replaced with hydrogen three times, and the resulting mixture was heated to 130° C. and stirred for 6 hours under a hydrogen pressure of 1 to 30 bar. Detected by high performance liquid chromatography, the HMF conversion rate and the resulting DMF yield are shown in the table below.

[0043] hydrogen pressure

[0044] 1 bar

Embodiment 3

[0045] The Fe of different ruthenium mass fractions of embodiment 3 3 o 4 Preparation and Catalytic Activity of C-Ru Catalyst

[0046] Fe with different ruthenium mass fractions 3 o 4 The preparation method of C-Ru catalyst is the same as embodiment 1, only changes RuCl in step 3 3 ·xH 2 The addition amount of O (2.5-25mg), can obtain the active component metal ruthenium mass percentage in 1%~10% Fe 3 o 4 C-Ru catalyst.

[0047] HMF (50.4mg), THF (12mL) and the above-mentioned ruthenium mass fraction are 1%~10% Fe 3 o 4 The C-Ru catalyst (65mg) was added into a 50mL stainless steel reaction kettle, and the air was replaced with hydrogen three times, and the resulting mixture was heated to 130° C. under 15 bar hydrogen pressure and stirred for 6 hours. Detected by high performance liquid chromatography, HMF conversion rate and gained DMF yield are as follows:

[0048] The mass fraction of Ru in the catalyst

[0049] 10%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com