Preparation method of wheat protolysate

A technology for wheat hydrolyzed protein and wheat protein, which is applied in the field of food processing, can solve the problems of long time consumption, bitter taste in the taste of enzymatic hydrolysis products, and large amount of enzymes, and achieves increased solubility, suitable for large-scale production, and small peptides. high content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

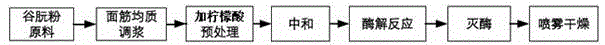

[0069] Example 1 A preparation method of wheat hydrolyzed protein, comprising the steps of:

[0070] (1) Blending : Wheat protein is used as raw material, which is dispersed and input into the feeding tank through a homogenizer while adding water for slurry adjustment, and a wheat protein suspension with a mass concentration of 20% is prepared.

[0071] (2) Pretreatment: In terms of mass percentage, the mass concentration of citric acid in the wheat protein suspension is 0.15%. The reaction temperature is 70°C, the stirring speed is 8r / min, and the pretreatment is 15min.

[0072] (3) Neutralization: After pretreatment, adjust the pH to 6.0 with 10% sodium oxide solution.

[0073] (4) Enzymolysis reaction: Add 1‰ alkaline protease and 4‰ neutral protease according to the dry matter weight of the above feed solution, and perform enzymolysis reaction for 2 hours at 50°C and stirring speed 8r / min.

[0074] (5) Enzyme inactivation: heat up the material obtained in (4) to 85°...

Embodiment 2

[0077] Embodiment 2 A kind of preparation method of wheat hydrolyzed protein, comprises the steps:

[0078] (1) Slurry: Wheat protein is used as raw material, which is dispersed and input into the feeding tank through a homogenizer while adding water to prepare a wheat protein suspension with a mass concentration of 20%.

[0079] (2) Pretreatment: In terms of mass percentage, the mass concentration of citric acid in the wheat protein suspension is 0.1%. The reaction temperature is 80°C, the stirring speed is 10r / min, and the pretreatment is 25min.

[0080] (3) Neutralization: After pretreatment, adjust the pH to 6.0 with 10% sodium oxide solution.

[0081] (4) Enzymolysis reaction: add 1.5‰ alkaline protease and 2.5‰ neutral protease according to the dry matter weight of the above feed solution, and perform enzymolysis reaction for 2 hours at 50°C and stirring speed 8r / min.

[0082] (5) Enzyme inactivation: heat up the material obtained in (4) to 85°C, maintain for 20 min fo...

Embodiment 3

[0085] Embodiment 3 A kind of preparation method of wheat hydrolyzed protein, comprises the steps:

[0086] (1) Slurry mixing: Wheat protein is used as raw material, which is dispersed into the feeding tank through a homogenizer while adding water for slurry mixing, and made into a wheat protein suspension with a mass concentration of 25%.

[0087] (2) Pretreatment: In terms of mass percentage, the mass concentration of citric acid in the wheat protein suspension is 0.2%. The reaction temperature is 80°C, the stirring speed is 10r / min, and the pretreatment is 10min.

[0088] (3) Neutralization: After pretreatment, adjust the pH to 6.0 with 10% sodium oxide solution.

[0089] (4) Enzymolysis reaction: Add 2‰ alkaline protease and 4‰ neutral protease according to the dry matter weight of the above feed solution, and perform enzymolysis reaction for 3 hours at 50°C and stirring speed 8r / min.

[0090] (5) Enzyme inactivation: heat the material obtained in (4) to 88°C, maintain f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com