Hydraulic control system

A technology of hydraulic control system and controller, which is applied in fluid pressure actuation system components, fluid pressure actuation devices, accumulator devices, etc., and can solve problems such as difficulty in adaptation and difficulty in carrying large accumulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

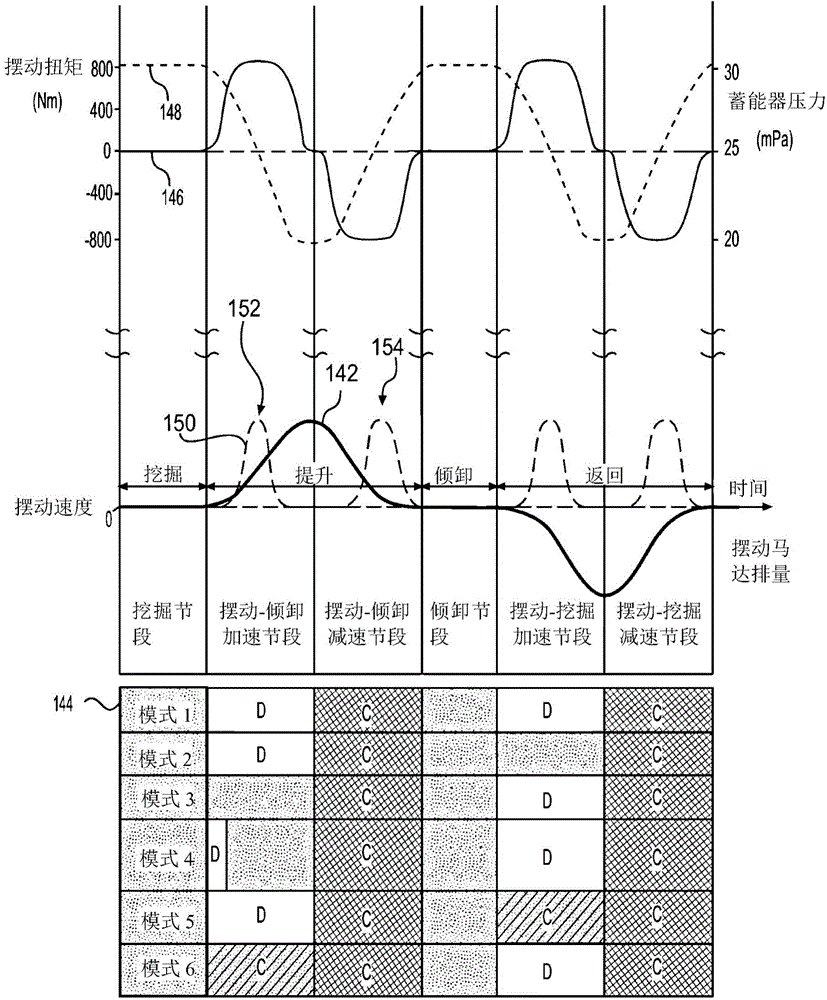

Image

Examples

Embodiment Construction

[0012] figure 1 An exemplary machine 10 is shown having a number of systems and components that cooperate to excavate and load material onto nearby transport vehicles 12 . In one example, machine 10 may embody a hydraulic excavator. It is contemplated, however, that machine 10 may embody another swing-type excavation or material handling machine, such as a backhoe, face shovel, dragline, or other similar machine. Among other things, machine 10 may include an implement system 14 configured to move implement 16 between a digging position 18 in a ditch or at a pile of ground and a dumping position 20 (eg, on top of transport vehicle 12 ). In addition, machine 10 may include an operator station 22 for manually controlling implement system 14 . It is contemplated that machine 10 may perform operations other than truck loading, such as lifting, trenching, and material handling, if desired.

[0013] Implement system 14 may include linkage structures actuated by fluid brakes to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com