Air-staged cooling device for batteries of electric vehicle

An air grading and cooling device technology, applied in the direction of batteries, electrical components, secondary batteries, etc., can solve the problems of rapid battery aging, battery pack temperature rise, battery pack failure, etc., and achieve a simple and reliable structure and uniform temperature distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

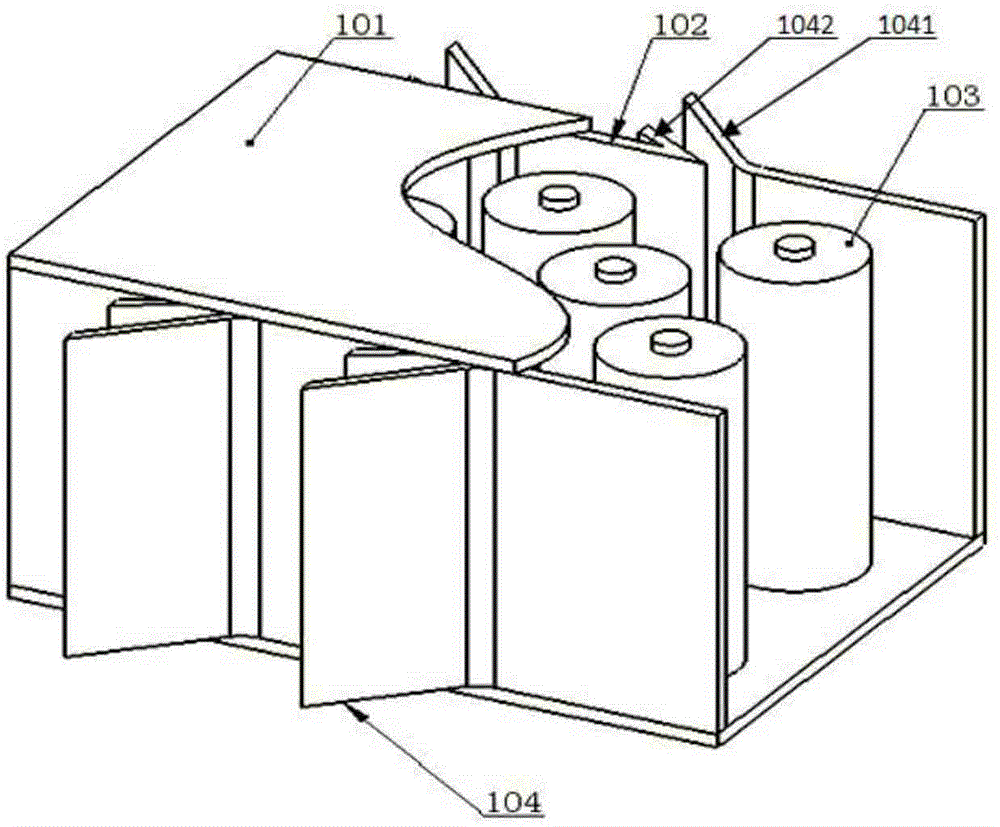

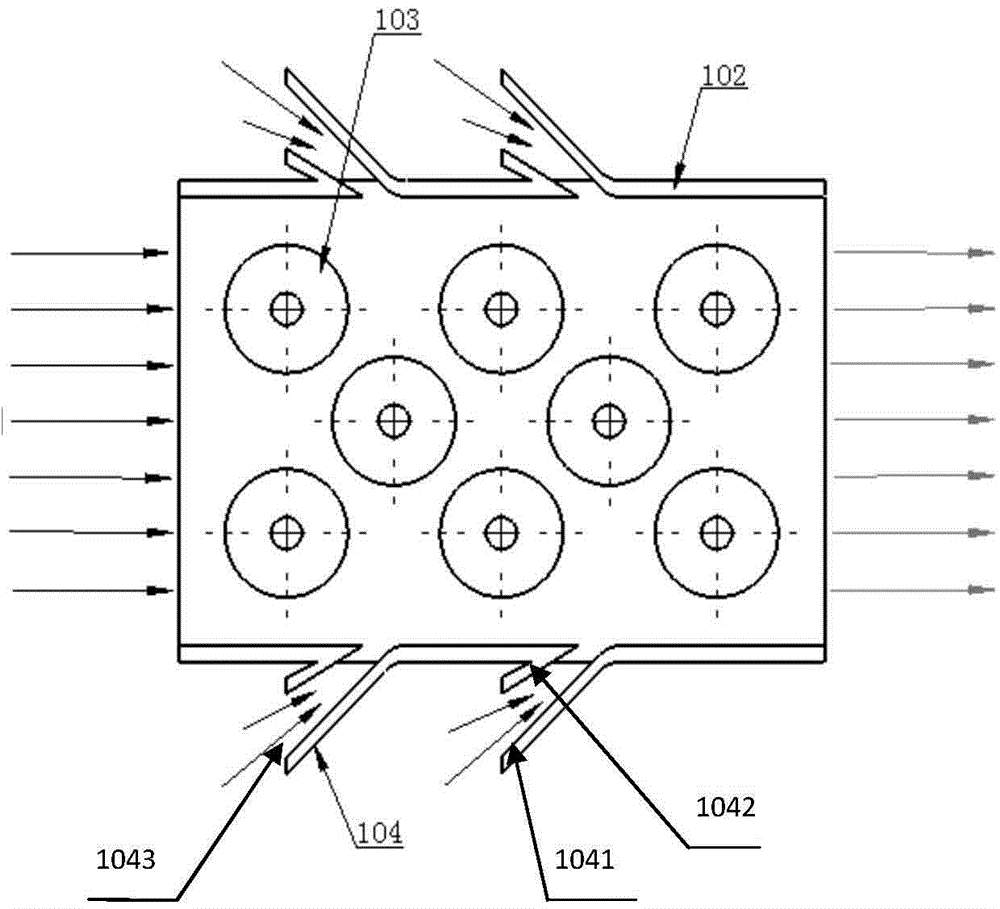

[0027] Such as figure 1 and figure 2 As shown, an electric vehicle battery air classification cooling device includes a rectangular parallelepiped battery box 101 for installing battery modules 103, eight cylindrical battery modules 103 are arranged laterally in the battery box 101 along the cooling air flow direction, each The battery modules 103 are arranged in a staggered arrangement. The battery box side walls 102 on the left and right sides of the battery box 101 are symmetrically provided with four air classification guides 104 that extend outwards and guide air into the battery box 101 along the direction of air flow. The height of the guides 104 is It is the same height as the side of the battery case.

[0028] The air classification deflector 104 includes a first wind deflector 1041 and a second wind deflector 1042 connected to the side wall 102 of the battery box, and is sealed and connected with the first wind deflector 1041 and the second wind deflector 1042 T...

Embodiment 2

[0034] see Figure 4 ~ Figure 5 The difference between this embodiment and Embodiment 1 is that in this embodiment, the battery modules 103 are arranged in a row, the number of battery modules 103 is also eight, and the flow guiding device 104 is located in two rows of battery modules Between 103.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is that: the battery case 101 is cylindrical, and the battery modules 103 are longitudinally arranged in the battery case 101 along the cooling air flow direction.

[0037] The above-mentioned embodiments can also be used to deal with occasions other than electric vehicles that require cooling of battery packs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com