Multilayer positive plate, production method of positive plate and lithium ion battery

A positive electrode sheet and positive electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as degradation, positive electrode material gram capacity attenuation, lithium source loss, etc., achieve good safety performance, increase gram capacity, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 A two-layer positive electrode sheet

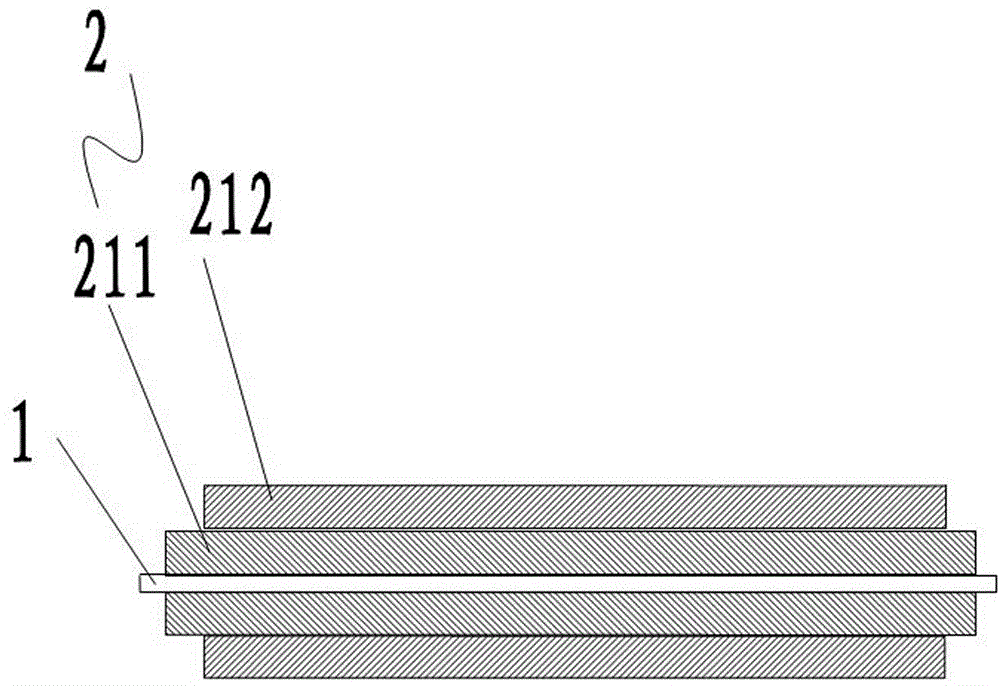

[0026] Such as figure 1 As shown, a two-layer positive electrode sheet includes a current collector 1 and an electrode material layer 2 coated on the surface of the current collector 1; the electrode material layer 2 includes two mixed slurry layers; the two mixed slurry layers 2 are successively layer coated on the surface of current collector 1. The mixed slurry layer 2 is a mixture of positive electrode material, conductive agent and binder. Lithium cobalt oxide and lithium nickel cobalt manganese oxide are selected as the positive electrode material. The lithium cobalt oxide, the conductive agent and the binder are mixed according to the ratio of 94.5:2.5:3 by weight to prepare the lithium cobalt oxide mixture. Mix nickel-cobalt-lithium-manganese-oxide, conductive agent and binder according to the ratio of 95:2:3 by weight to make nickel-cobalt-lithium-manganese-oxide mixture. The lithium cobalt oxide mixture is f...

Embodiment 2

[0029] Example 2 Preparation of 100 kg of two-layer positive electrode sheet

[0030] A method for making a two-layer positive electrode, comprising the following steps:

[0031] (1) Lithium cobalt oxide and lithium nickel cobalt manganese oxide were selected as positive electrode materials, and conductive carbon black was used as conductive agent to dry and remove moisture. The drying conditions are controlled as follows: the temperature is 70° C. to 120° C., and the time is 2 to 4 hours.

[0032] (2) Use carbon black as the conductive agent, use polyvinylidene fluoride as the binder, and use N-methylpyrrolidone as the dispersant to make the positive electrode material, conductive agent and binder into a slurry; 35 kg of N -Methylpyrrolidone and 3 kg of polyvinylidene fluoride binder are put into a container and stirred to form a glue, then 2.5 kg of carbon black conductive agent is placed in the glue for dispersion, and finally dried in step (1) The final 95 kg of lithium ...

Embodiment 3

[0037] Example 3 A lithium-ion battery containing two layers of positive electrodes

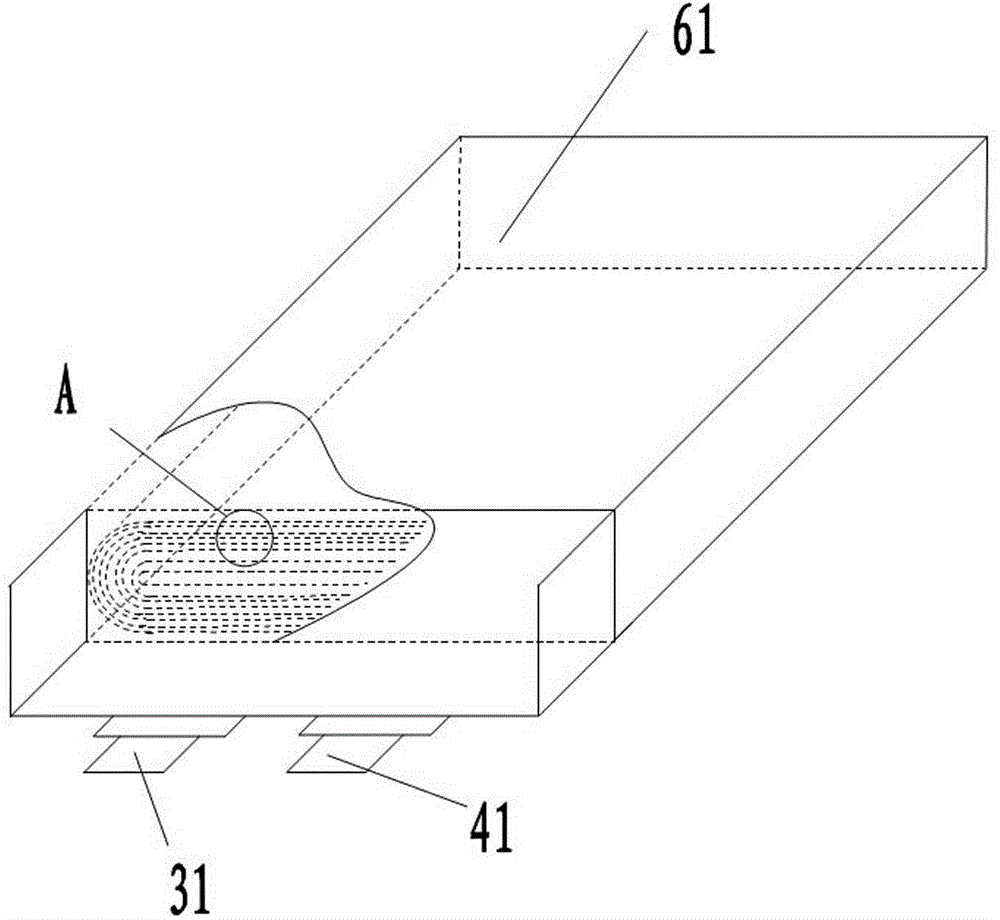

[0038] Such as figure 2 and image 3 As shown, a lithium ion battery comprising the two-layer positive electrode sheet described in Example 1. Such as figure 2 Shown, a kind of lithium ion battery comprises two layers of positive electrode sheet 31, negative electrode sheet 41 and is arranged between two layers of positive electrode sheet 31 and negative electrode sheet 41 and is provided with PE separator 51, described two layers of positive electrode sheet 31, negative electrode sheet 41 and the PE diaphragm 51 are packaged in the aluminum-plastic film 61, and the electrolyte is injected into the aluminum-plastic film to form a lithium-ion battery.

[0039] Such as image 3 As shown, the two-layer positive electrode sheet in this embodiment includes a current collector 1 and an electrode material layer 2 coated on the surface of the current collector 1; the electrode material layer 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com