In-situ composite system based on carbon quantum dot/manganese dioxide nanometer sheet layer and using method for detecting content of glutathione

A technology of glutathione content and carbon quantum dots, applied in the field of biological analysis, can solve the problems of high cost of gold and silver nanoclusters, unsuitable for large-scale promotion, destruction of biological samples, etc. High, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, adding carbon quantum dots to the 2-(N-morpholine) ethanesulfonic acid buffer system to prepare a carbon quantum dot solution with a concentration of 0.1 mg / ml;

[0031] Step 2. Add 5 mL of 0.2 mM potassium permanganate aqueous solution to 60 μL of the above-mentioned carbon quantum dot solution. After fully mixing, add 3 mL of deionized water to the mixed solution to prepare a reaction mixture;

[0032] Step 3: Sonicate the above reaction mixture for 20 minutes until a brown precipitate is formed. After centrifugal purification, carbon quantum dots / manganese dioxide sheet nanocomposites are obtained, and then dispersed in 8 mL of deionized water to obtain carbon quantum dots. / Manganese dioxide sheet nanocomposite system.

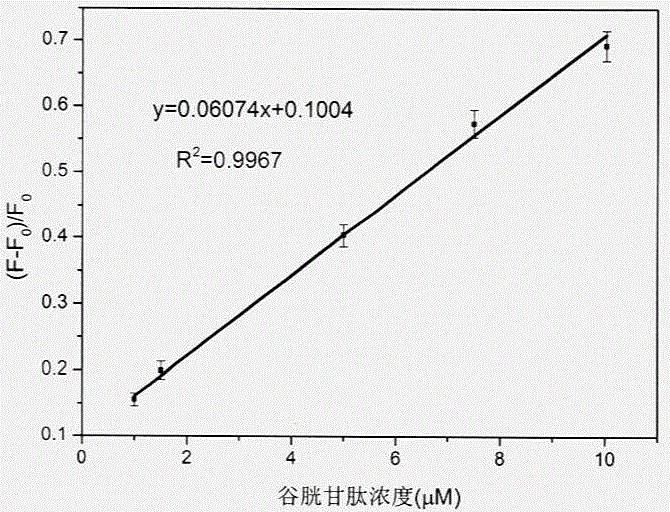

[0033] Step 4. Use the in-situ composite system based on carbon quantum dots / manganese dioxide nanosheets obtained above as a detection solution, and combine it with glutathione at concentrations of 0 μM, 1 μM, 1.5 μM, 5 μM, 7.5 μM, and 10 μ...

Embodiment 2

[0036] Step 1, adding carbon quantum dots to the 2-(N-morpholine) ethanesulfonic acid buffer system to prepare a carbon quantum dot solution with a concentration of 0.5 mg / ml;

[0037] Step 2. Add 3 mL of 0.5 mM potassium permanganate aqueous solution to 18 μL of the above-mentioned carbon quantum dot solution, and after fully mixing, add 4.5 mL of deionized water to the mixed solution to prepare a reaction mixture;

[0038] Step 3. Ultrasonic the above reaction mixture for 25 minutes until a brown precipitate is formed. After centrifugal purification, carbon quantum dots / manganese dioxide lamellar nanocomposites are obtained, and then dispersed into 12mL deionized water to obtain carbon quantum dots. / Manganese dioxide sheet nanocomposite system.

[0039] Step 4. Use the in-situ composite system based on carbon quantum dots / manganese dioxide nanosheets obtained above as a detection solution, and combine it with glutathione at concentrations of 0 μM, 1 μM, 1.5 μM, 5 μM, 7.5 μM...

Embodiment 3

[0043] Step 1, adding carbon quantum dots to the 2-(N-morpholine) ethanesulfonic acid buffer system to prepare a carbon quantum dot solution with a concentration of 1.0 mg / ml;

[0044] Step 2. Add 2 mL of potassium permanganate aqueous solution with a concentration of 1.0 mM to 12 μL of the above-mentioned carbon quantum dot solution, and after fully mixing, add 6 mL of deionized water to the mixed solution to prepare a reaction mixture;

[0045] Step 3. Ultrasonic the above reaction mixture for 35 minutes until a brown precipitate is formed. After centrifugal purification, carbon quantum dots / manganese dioxide lamellar nanocomposites are obtained, and then dispersed into 16 mL of deionized water to obtain carbon quantum dots. / Manganese dioxide sheet nanocomposite system.

[0046] Step 4. Use the in-situ composite system based on carbon quantum dots / manganese dioxide nanosheets obtained above as a detection solution, and combine it with glutathione at concentrations of 0 μM, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com