Novel drying machine

A dryer, a new type of technology, applied in the direction of dryer, drying, progressive dryer, etc., can solve the problems of high labor cost, low degree of automation, poor drying efficiency, etc., and achieve the improvement of drying efficiency and automation High degree of effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Although the present invention has been described with reference to specific embodiments, those skilled in the art will be able to make obvious modifications and modifications to the present invention after reading the above description without departing from the intent and essence of the present invention. The present invention intends to include such modifications and modifications within the scope of the claims.

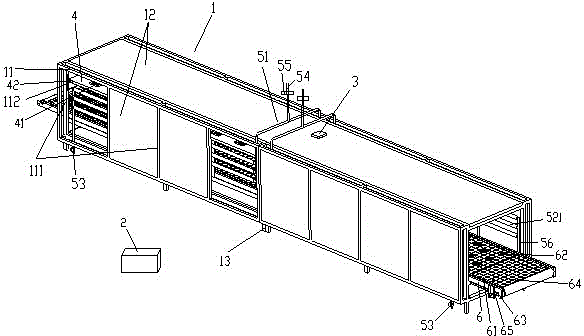

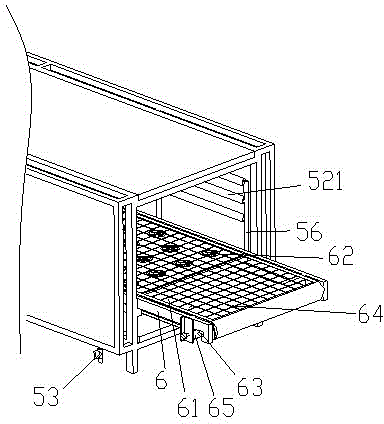

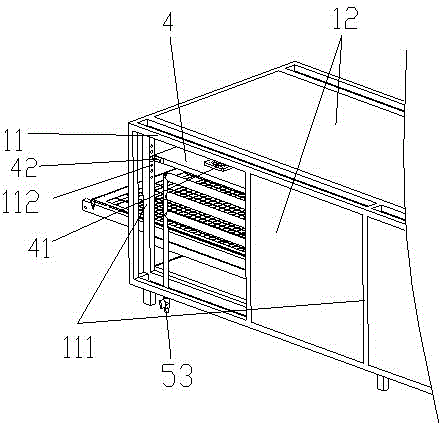

[0026] A new type of dryer such as Figure 1 to Figure 7 As shown, it includes a chassis 1 and an electric control cabinet 2. The chassis 1 is a long chassis structure with openings at both ends. The length of the chassis 1 is set according to the time required for drying the product and the speed at which the product is put in. Definitely, the drying machine of the present invention is applied to the drying of the foam products that are automatically put in after the molding process of the molding machine. The speed of drying the products and the speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap