Fixed-torque gasket

A technology of constant torque and washer, applied in the direction of threaded fasteners, connecting components, screws, etc., can solve the problems of insufficient screwing of bolts and screwing standards, and achieve the effect of improving work efficiency, easy implementation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

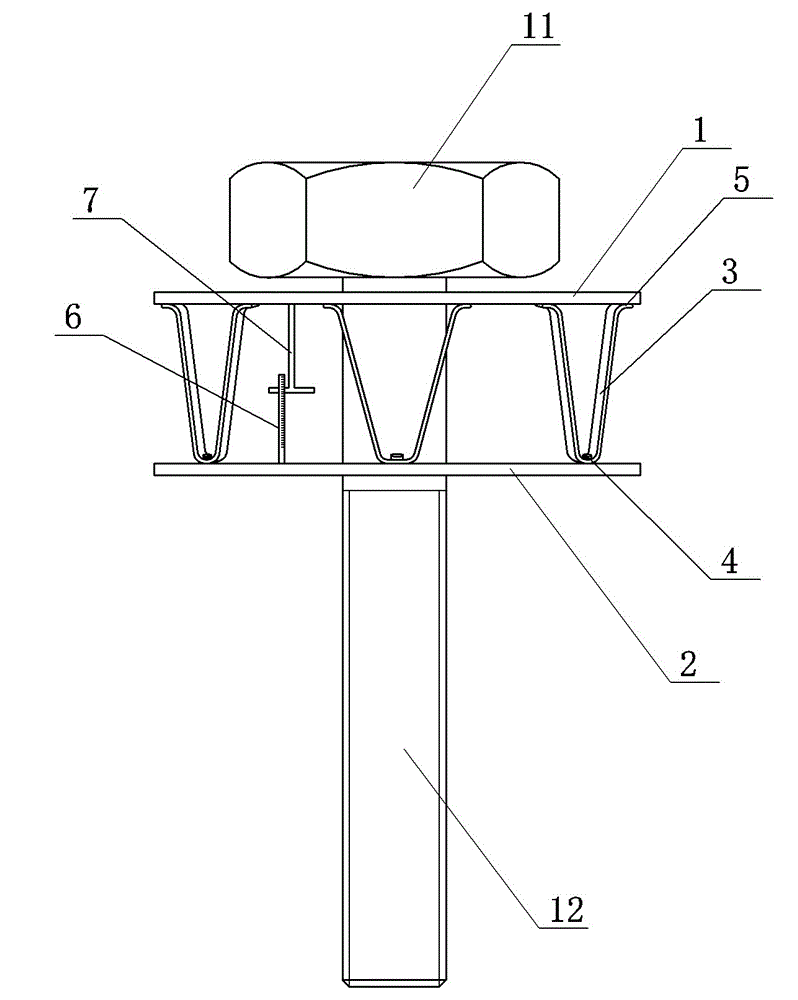

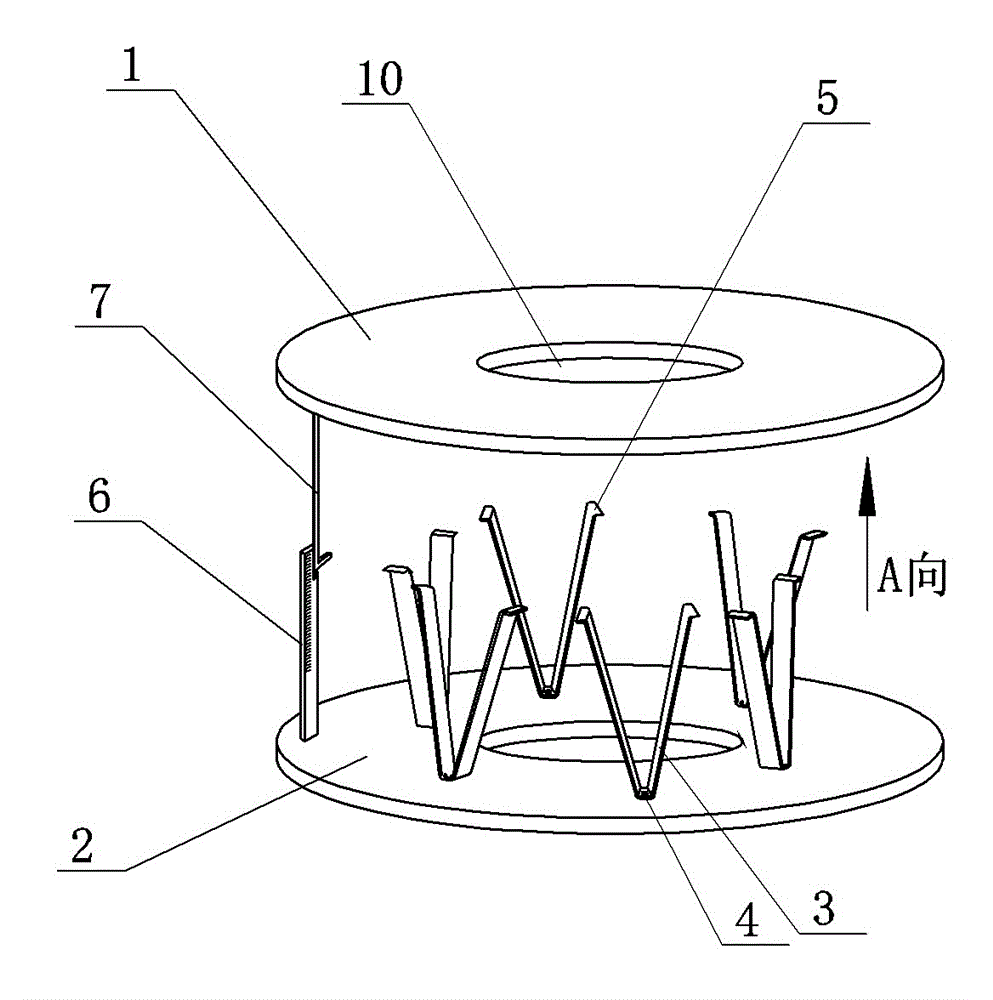

[0029] Embodiment 1: The first constant torque washer, see figure 1 and figure 2 , The middle parts of the upper washer 1 and the lower washer 2 are respectively provided with corresponding central holes 10 for passing through the mounting bolts. A plurality of symmetrical elastic bodies are distributed and fixed around the central hole 10 of the lower gasket 2 , such as V-shaped elastic pieces 3 . The upper end of each symmetrical elastic body is slidingly matched with the inner surface of the upper gasket 1; and a positioning mechanism for determining the distance between the upper gasket 1 and the lower gasket 2 is provided.

[0030] In this embodiment, the positioning mechanism is to respectively fix the scale 6 and the reference rod 7 on the inner surfaces of the two washers along the axial direction, and the side or end of the reference rod 7 is provided with a reference line corresponding to the marking line of the scale 6 . In order to prevent the upper washer 1 and...

Embodiment 2

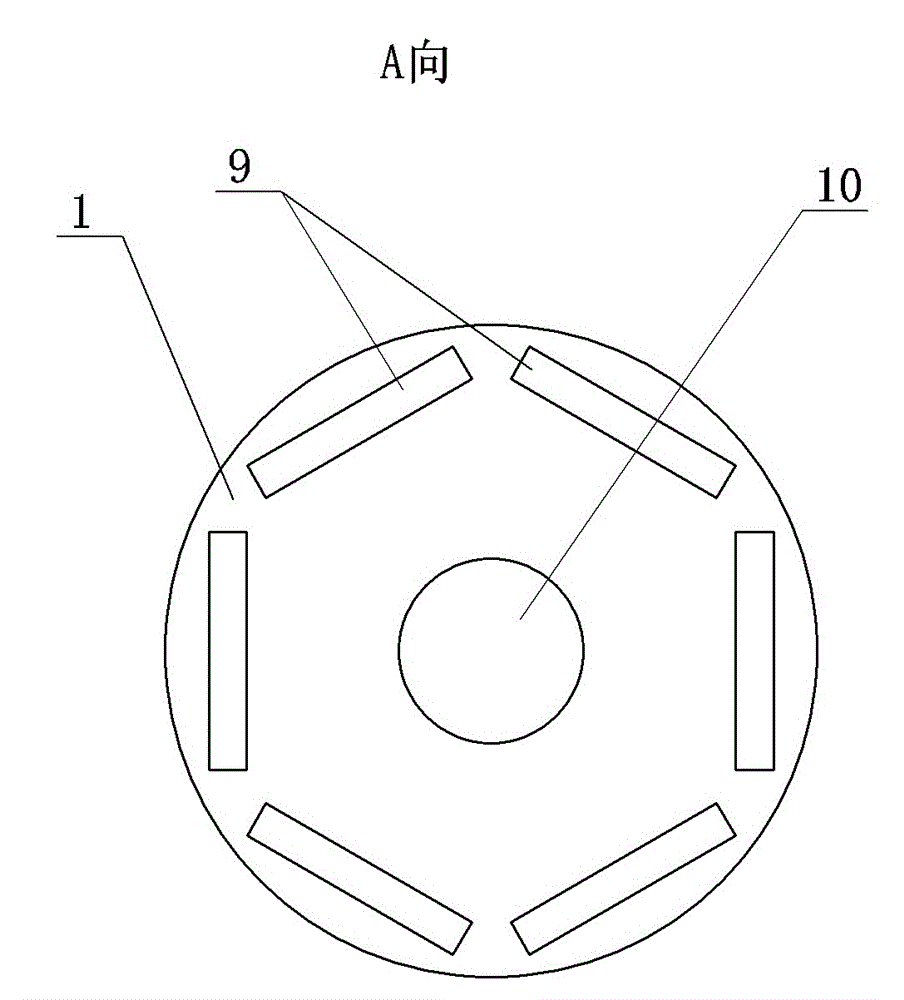

[0033] Embodiment 2: The second constant torque washer, see figure 1 , figure 2 and image 3 , The middle parts of the upper washer 1 and the lower washer 2 are respectively provided with corresponding central holes 10 for passing through the mounting bolts. A plurality of V-shaped elastic pieces 3 are distributed and fixed around the central hole 10 of the lower gasket 2 . The corners of the V-shaped shrapnel 3 are fixed on the inner surface of the lower gasket 2 by rivets or welding spots 4, and the upper ends of the V-shaped shrapnel 3 are respectively provided with sliding feet 5 . The inner surface of the upper gasket 1 is provided with chutes 9 corresponding to the number and corresponding positions of the V-shaped shrapnel 3. Each chute 9 is arranged around the center hole 10 of the upper washer 1. respectively located in the chute 9, and sliding fit.

[0034] The combination of the chute 9 and the sliding foot 5 can not only prevent the relative rotation of the up...

Embodiment 3

[0036] Embodiment 3: The third constant torque washer, see figure 1 , figure 2 and Figure 4 , The middle parts of the upper washer 1 and the lower washer 2 are respectively provided with corresponding central holes 10 for passing through the mounting bolts. A plurality of V-shaped elastic pieces 3 are distributed and fixed around the central hole 10 of the lower gasket 2 . The corners of the V-shaped shrapnel 3 are fixed on the inner surface of the lower gasket 2 by rivets or welding spots 4, and the upper ends of the V-shaped shrapnel 3 are respectively provided with sliding feet 5 . The inner surface of the upper gasket 1 is provided with chutes corresponding to the number and positions of the V-shaped shrapnel 3, and the chute intervals are misplaced: the adjacent chute is divided into an outer layer chute 9a and an inner layer chute 9b, adjacent The center of the chute is not on the same circumferential surface, and the sliding feet 5 on the upper ends of each V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com