Hydraulic support linkage self-moving device and hydraulic support linkage self-moving method

A hydraulic support and self-moving technology, which is applied to the mine roof support, earth square drilling, mining equipment, etc., can solve the problems of cumbersome construction process, offset and dislocation of three hydraulic supports, unable to maintain the empty roof area, etc., to eliminate Injury to people due to broken connectors and broken wire ropes, improved removal speed and support efficiency, construction safety, rapid removal and roof support effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

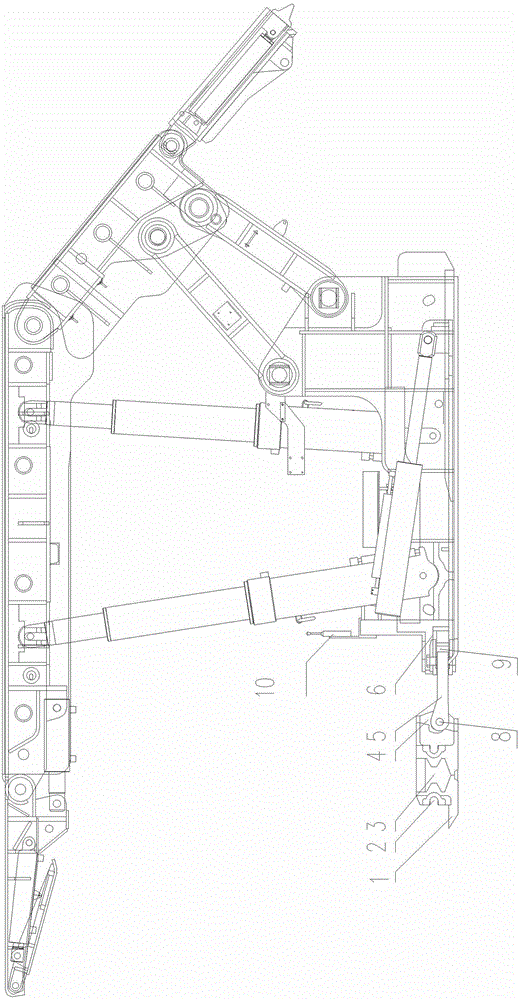

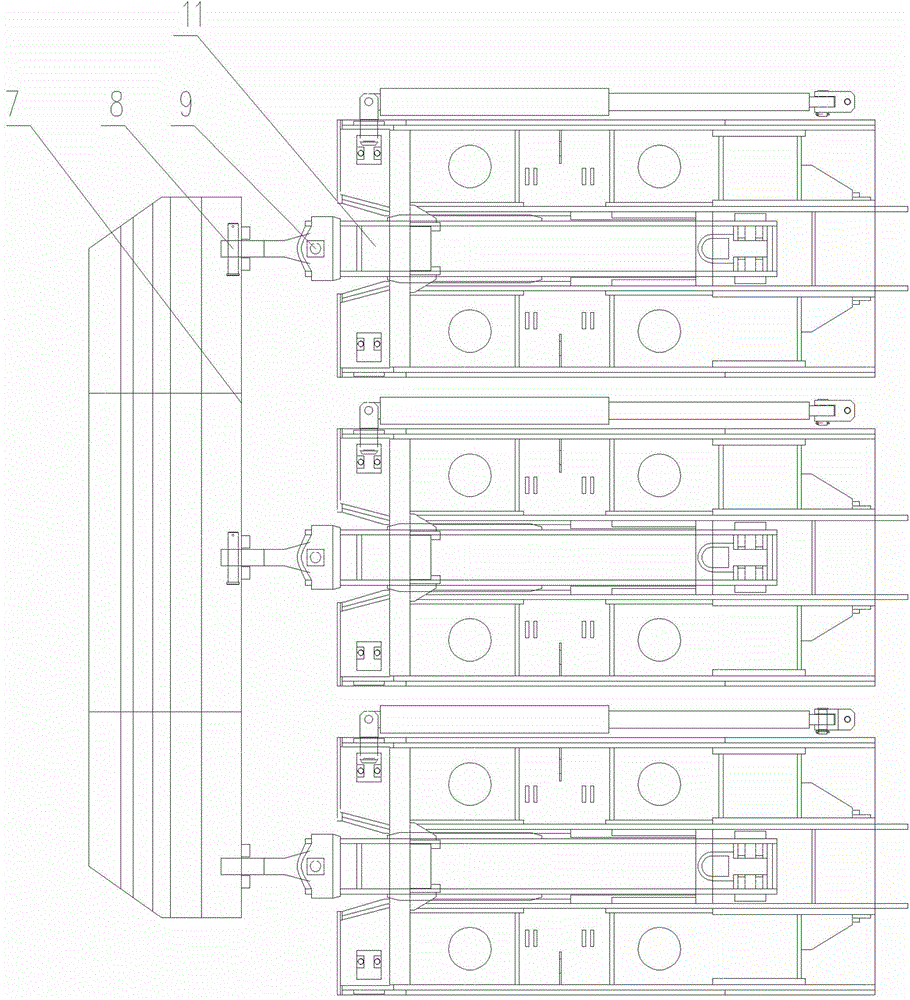

[0018] The present invention as figure 1 as shown,

[0019] A hydraulic support combined self-moving device, including a hydraulic support 6 with a horizontal hydraulic push rod 5 and a control valve group, characterized in that the hydraulic support 6 is three groups of hydraulic support a, hydraulic support b and hydraulic support c. It also includes a cross bar 3 and a push rod 5. The front end of the cross bar 3 is provided with a shovel plate 1, and the rear end of the cross bar 3 is provided with a pin lug 4 to connect three groups of uniformly distributed push rods 5 through the pin shaft a8. The push rod 5 It is connected with the horizontal hydraulic push rod 11 of the hydraulic support 6 through the pin b9.

[0020] According to the hydraulic support 6 combined self-moving device, it is characterized in that the cross bar 3 is divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com